Abrasion-resistant grate bar

A sieve bar and screening technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of increasing the weight of the sieve bar, the failure of the sieve plate, and the coarsening of the material, so as to increase the strength of the mechanical connection, guarantee the service life, The effect of improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

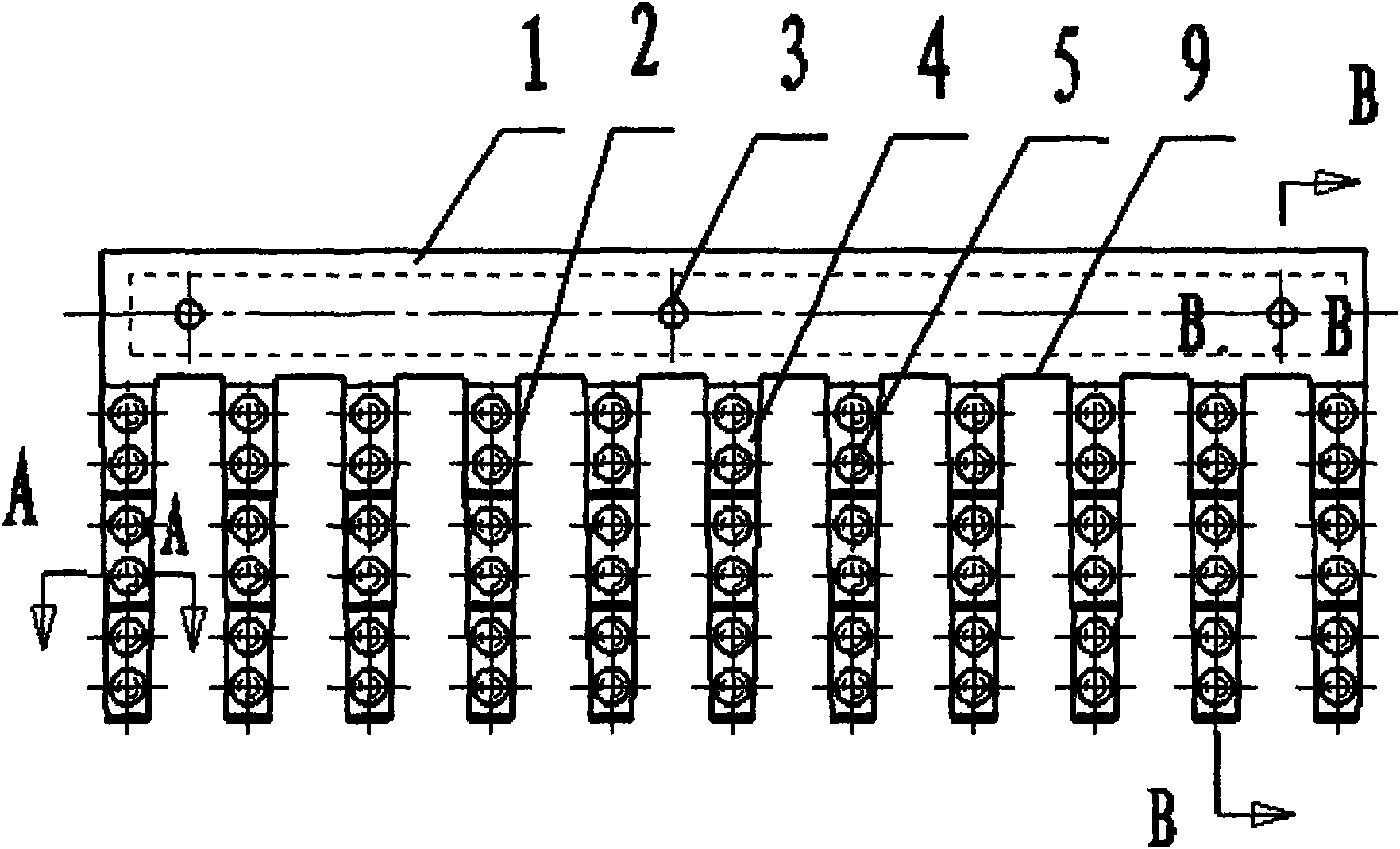

[0021] figure 1 Shown is the overall structure diagram of the wear-resistant sieve bar. In the figure, 1 is the back of the comb sieve bar, 2 is the comb part of the comb sieve bar, and 3 is the installation hole of the comb sieve bar. Through this hole, the comb The toothed sieve bar is installed on the sieve plate frame to form a comb sieve plate. 4 is a wear-resistant composite layer, and the wear-resistant composite layer is made of ceramic material, 5 is a hole on the wear-resistant composite layer, and 9 is the edge of the wear-resistant screen bar back.

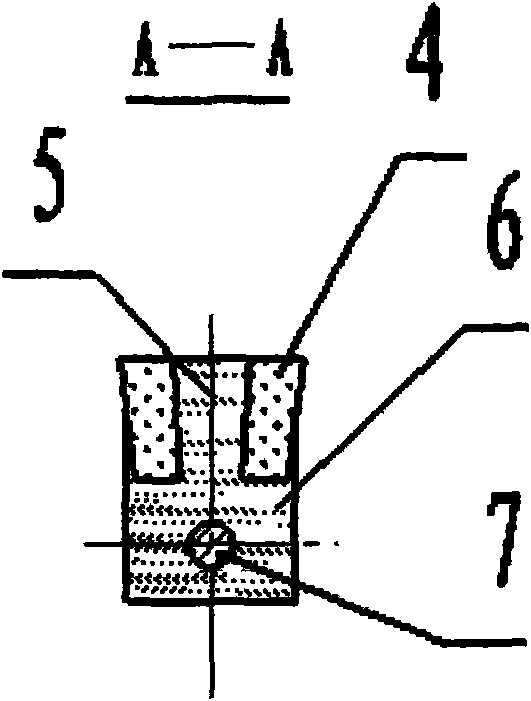

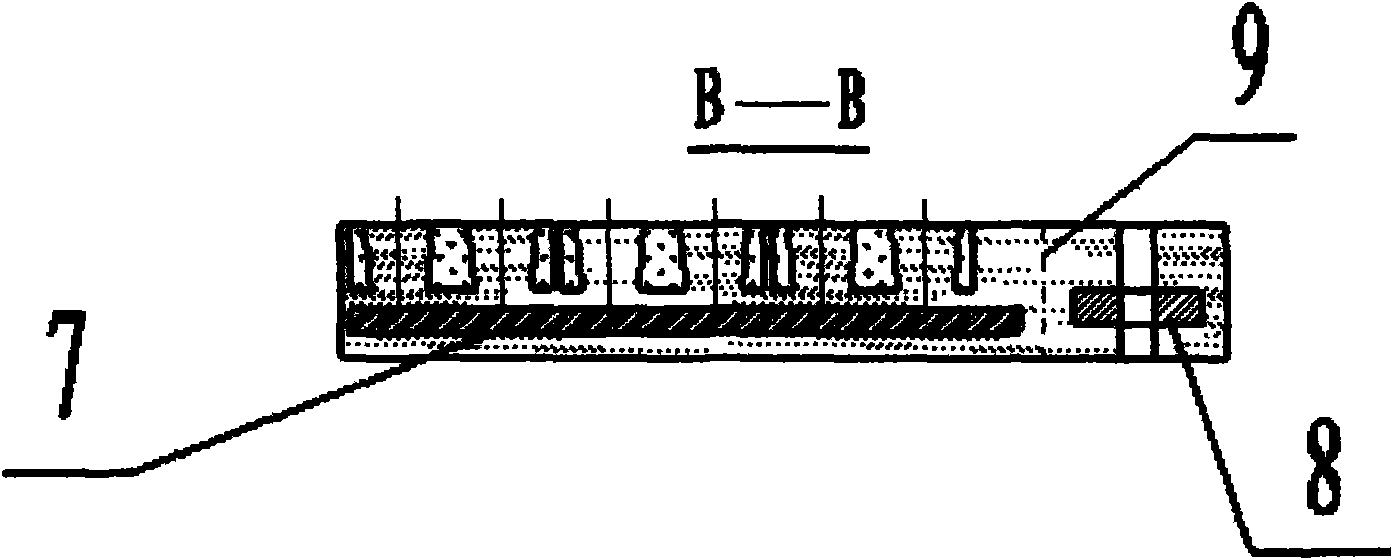

[0022] figure 2 show figure 1 The enlarged view of the subdivision structure along the A-A plane in the middle, in which 4 is the wear-resistant composite layer, 5 is the hole on the wear-resistant composite layer, and 6 is the matrix of polymer elastic material. In this embodiment, the matrix adopts polyurethane elastomer material, 7 is a spring steel wire vulcanized in polyurethane. It can be seen from these two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com