Surfacing flux-cored wire and manufacturing method thereof

A technology of welding wire and welding flux, applied in the field of surfacing flux-cored welding wire and its preparation, can solve the problems of unsatisfactory and uneven surfacing layer, and achieve the effect of saving raw material cost and beautiful welding seam shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

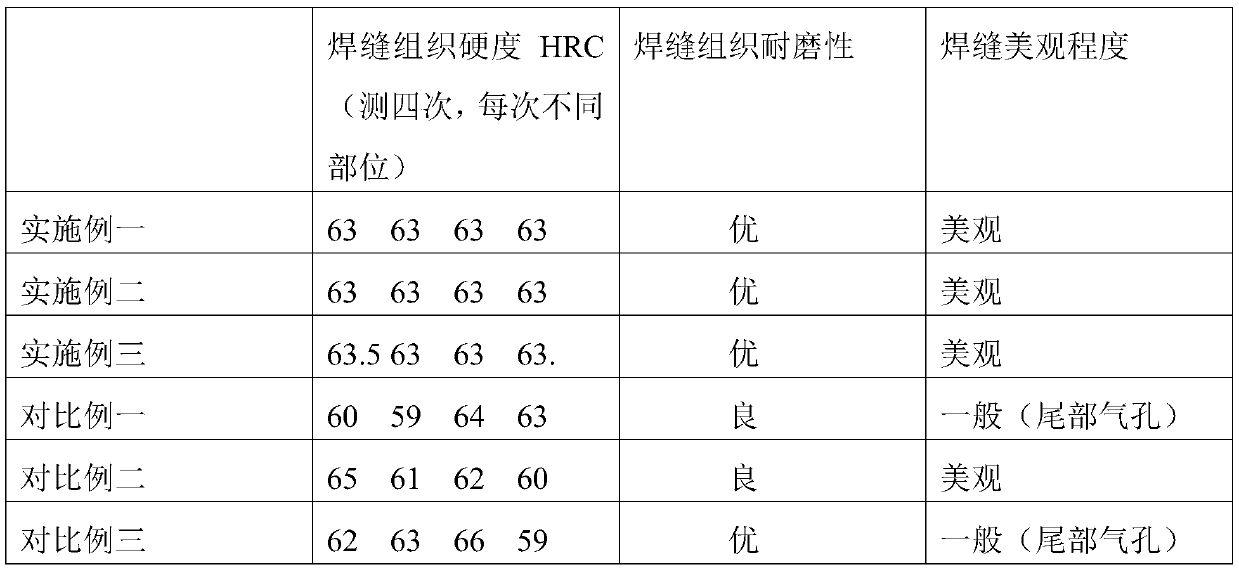

Examples

preparation example Construction

[0037] The present invention also provides a preparation method of surfacing welding flux-cored wire, the steps of the method include:

[0038] The powder of each component is sieved separately;

[0039] Dry the sifted powder;

[0040] Mix the dried components according to the corresponding mass percentages, fully mix the prepared medicinal powder with a three-dimensional powder mixer to obtain a mixture, keep it dry until it is loaded into the medicinal powder hopper of the molding production line;

[0041] When the U-shaped steel strip passes through the powder feeder of the forming production line, the mixture is added to the U-shaped steel strip to make surfacing flux-cored wire.

[0042] The addition of alloying elements refines the structure of the surfacing layer, and the refinement of the structure is equivalent to an increase in the number of hard phases. To a certain extent, the harmful effects caused by grinding and peeling are reduced, thereby improving wear resis...

Embodiment 1

[0049] A surfacing welding flux-cored welding wire, the components it contains and the mass percentage of each component are as follows:

[0050] Marble 3%;

[0051] Fluorite 4%;

[0052] Silicate 2%;

[0053] graphite 5%;

[0055] High carbon ferrochrome 66%.

[0056] The steps of the preparation method of the surfacing flux-cored wire include:

[0057] The powder of each component is sieved separately;

[0058] Dry the sifted powder;

[0059] Mix the dried components according to the corresponding mass percentages, fully mix the prepared medicinal powder with a three-dimensional powder mixer to obtain a mixture, keep it dry until it is loaded into the medicinal powder hopper of the molding production line;

[0060] When the U-shaped steel strip passes through the powder feeder of the forming production line, the mixture is added to the U-shaped steel strip to make surfacing flux-cored wire.

[0061] The surfacing welding flux-cored wire pre...

Embodiment 2

[0063] A surfacing welding flux-cored welding wire, the components it contains and the mass percentage of each component are as follows:

[0064] Marble 7%;

[0065] Fluorite 8%;

[0066] Silicate 6%;

[0067] graphite 9%;

[0068] Metal chromium 10%;

[0069] High carbon ferrochrome 60%, 100% total.

[0070] The steps of the preparation method of the surfacing flux-cored wire include:

[0071] The powder of each component is sieved separately;

[0072] Dry the sifted powder;

[0073] Mix the dried components according to the corresponding mass percentages, fully mix the prepared medicinal powder with a three-dimensional powder mixer to obtain a mixture, keep it dry until it is loaded into the medicinal powder hopper of the molding production line;

[0074] When the U-shaped steel strip passes through the powder feeder of the forming production line, the mixture is added to the U-shaped steel strip to make surfacing flux-cored wire.

[0075] The surfacing welding flux-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com