Seawater corrosion resistance submerged arc welding wire rod, welding wire and application thereof

A technology of submerged arc welding wire and seawater resistance is applied in the field of corrosion-resistant welding materials and seawater-resistant welding materials, which can solve the problems of high cost and low Cr element content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

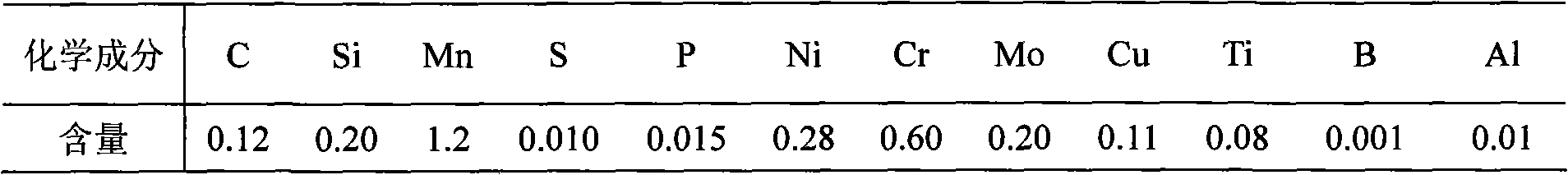

[0029] According to the composition design scheme of the present invention, that is to use Cr-Cu-Mo alloy system, low C, low Si, low S, low P, a certain amount of Ni, a small amount of Ti and Al, and make it according to the conventional welding wire production process, select SJ101 as flux. The chemical composition of the deposited metal of the obtained welding wire is shown in Table 1 below, and its mechanical properties are shown in Table 6.

[0030] Table 1 The finished chemical composition (wt%) of the welding wire of Example 1

[0031]

Embodiment 2

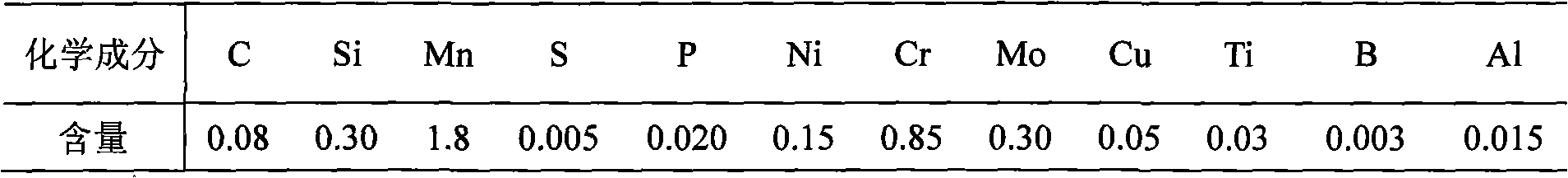

[0033] Production technology is identical with embodiment 1. The chemical composition of the deposited metal of the welding wire is shown in Table 2 below, and its mechanical properties are shown in Table 6.

[0034]The finished product chemical composition (wt%) of table 2 embodiment 2 welding wire

[0035]

Embodiment 3

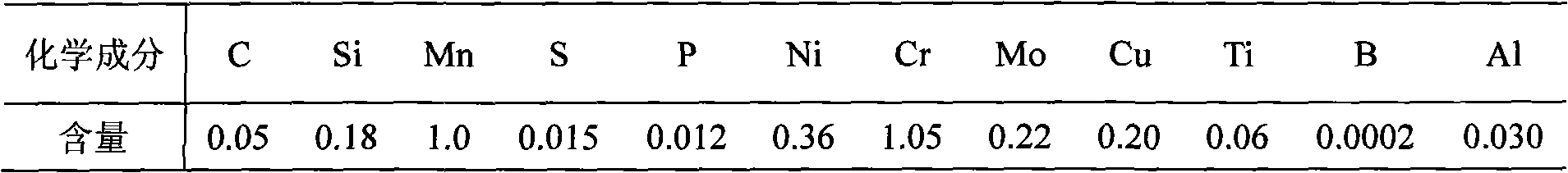

[0037] Production technology is identical with embodiment 1. The chemical composition of the deposited metal of the obtained welding wire is shown in Table 3 below, and its mechanical properties are shown in Table 6.

[0038] The finished product chemical composition (wt%) of table 3 embodiment 3 welding wire

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com