Epoxy powder primer used for anticorrosion paint for outer walls of deep sea oil transportation steel pipes and preparing method thereof

An oil transmission steel pipe, anti-corrosion coating technology, applied in anti-corrosion coatings, powder coatings, epoxy resin coatings and other directions, can solve the problems affecting the service life and safety of the seabed, poor mechanical properties at low temperature, poor adhesion of steel pipes, etc. The effects of seawater corrosion resistance, long service life, excellent water resistance and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

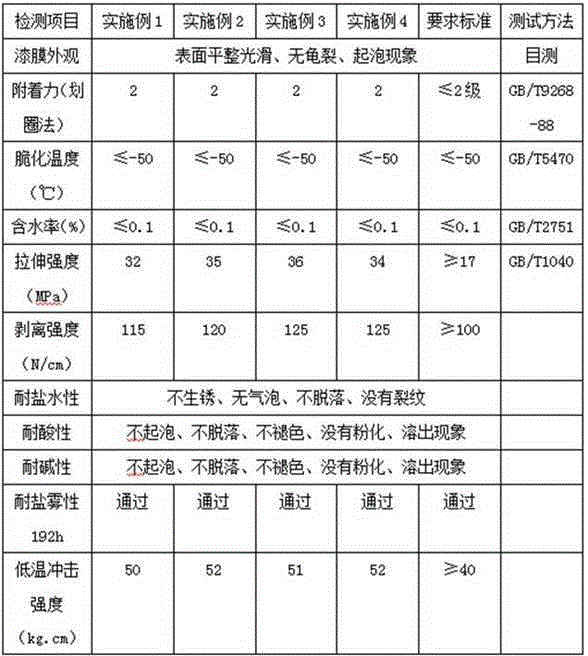

Examples

Embodiment 1

[0029] An epoxy powder primer used for the anticorrosion coating on the outer wall of deep-sea oil pipeline steel pipes consists of the following raw materials in parts by mass:

[0030] 40 parts of E-12 epoxy resin, 10 parts of novolak epoxy resin, 25 parts of filler, 9 parts of curing agent, 0.1 part of antioxidant, 0.2 part of coupling agent, 0.9 part of benzoate, 0.3 part of leveling agent 1 part, 1 part of graphene, 1 part of polyvinyl butyral, 3 parts of modified polytetrafluoroethylene wax micropowder, 0.2 part of rare earth chloride, and 1 part of pigment.

[0031] Described filler is made up of the raw material of following weight part:

[0032] 25 parts of precipitated barium sulfate, 6 parts of rutile titanium dioxide, 5 parts of active silica powder, 3 parts of mica powder, 1.5 parts of aluminum tripolyphosphate, and 0.2 parts of fumed silica.

[0033] The fineness of the precipitated barium sulfate, rutile titanium dioxide, active silicon micropowder and mica pow...

Embodiment 2

[0043] An epoxy powder primer used for the anticorrosion coating on the outer wall of deep-sea oil pipeline steel pipes consists of the following raw materials in parts by mass:

[0044] 45 parts of E-12 epoxy resin, 15 parts of novolak epoxy resin, 35 parts of filler, 10 parts of curing agent, 1 part of antioxidant, 0.5 part of coupling agent, 0.9 part of benzoate, 0.5 part of leveling agent 1 part, 2 parts of graphene, 1 part of polyvinyl butyral, 4 parts of modified polytetrafluoroethylene wax micropowder, 0.3 part of rare earth chloride, and 1 part of pigment.

[0045] Described filler is made up of the raw material of following weight part:

[0046] 30 parts of precipitated barium sulfate, 8 parts of rutile titanium dioxide, 7 parts of active silica powder, 4 parts of mica powder, 2.5 parts of aluminum tripolyphosphate, and 0.5 parts of fumed silica.

[0047] The fineness of the precipitated barium sulfate, rutile titanium dioxide, active silicon micropowder and mica pow...

Embodiment 3

[0057] An epoxy powder primer used for the anticorrosion coating on the outer wall of deep-sea oil pipeline steel pipes consists of the following raw materials in parts by mass:

[0058] 45 parts of E-12 epoxy resin, 20 parts of novolac epoxy resin, 40 parts of filler, 12 parts of curing agent, 0.5 parts of antioxidant, 0.7 parts of coupling agent, 1.4 parts of benzoate, 0.8 parts of leveling agent 2 parts, 2 parts of graphene, 2 parts of polyvinyl butyral, 4 parts of modified polytetrafluoroethylene wax micropowder, 0.4 part of rare earth chloride, 2 parts of pigment.

[0059] Described filler is made up of the raw material of following weight part:

[0060] 35 parts of precipitated barium sulfate, 10 parts of rutile titanium dioxide, 7 parts of active silica powder, 5 parts of mica powder, 3 parts of aluminum tripolyphosphate, and 1 part of fumed silica.

[0061] The fineness of the precipitated barium sulfate, rutile titanium dioxide, active silicon micropowder and mica po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com