Submarine cable with increased current-carrying capacity

A submarine cable and flow technology, which is applied in the direction of submarine cables, power cables with shielding layers/conductive layers, etc., can solve problems such as poor seawater corrosion resistance, decreased current carrying capacity of cables, and weakened service life of aluminum wires, etc., to avoid Effects of partial discharge, increased carrying capacity, and low power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

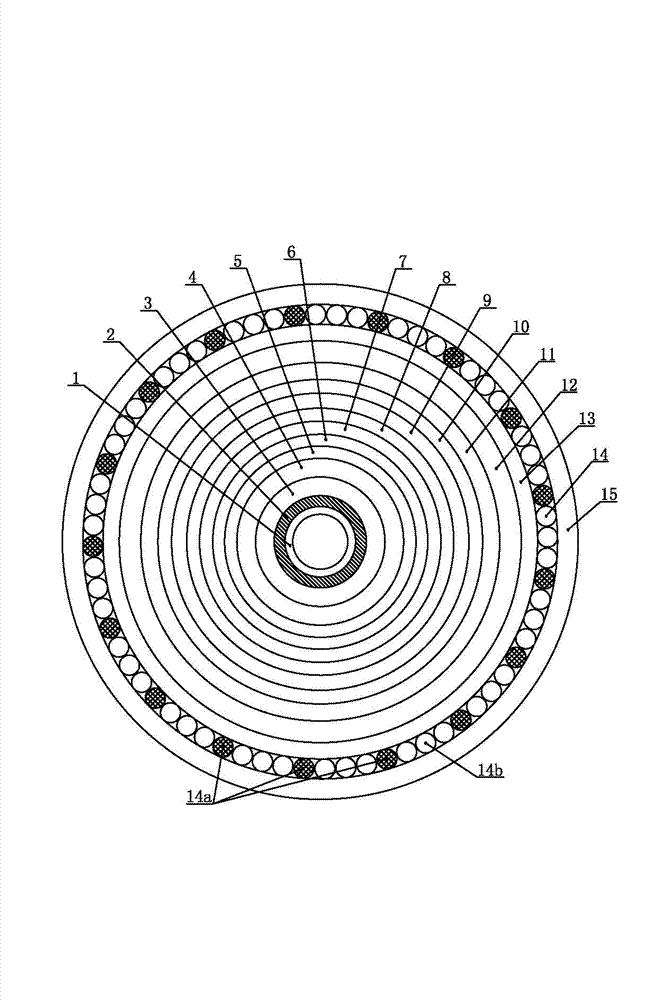

[0019] Such as figure 1 As shown, in a submarine cable with increased current carrying capacity of the present invention, the inner cavity of the tinned copper spiral tube 1 is provided with a hollow oil passage, and the aperture of the hollow oil passage is 18 mm; A highly conductive annealed annealed copper wire with a monofilament diameter of 2.57±0.03 mm constitutes the conductor layer 2 , and each highly conductive annealed annealed copper wire is spirally and closely arranged in a circular array on the outer periphery of the tinned copper spiral tube 1 .

[0020] The outer circumference of the conductor layer 2 is evenly wrapped with a carbon black paper conductor shielding layer 3, and the outer circumference of the carbon black paper conductor shielding layer 3 is evenly wrapped with an oil-filled high-voltage cable paper insulating layer 4. The thickness of the oil-filled high-voltage cable paper insulating layer 4 is 10±0.1mm. The outer circumference of the oil-fill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com