PE sheath material for submarine cable and preparation method thereof

A technology for submarine cables and sheathing materials, which is applied in the field of PE sheathing materials for submarine cables and their preparation, can solve the problems of shortened service life, performance degradation, poor performance of seawater corrosion resistance and microbial corrosion resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

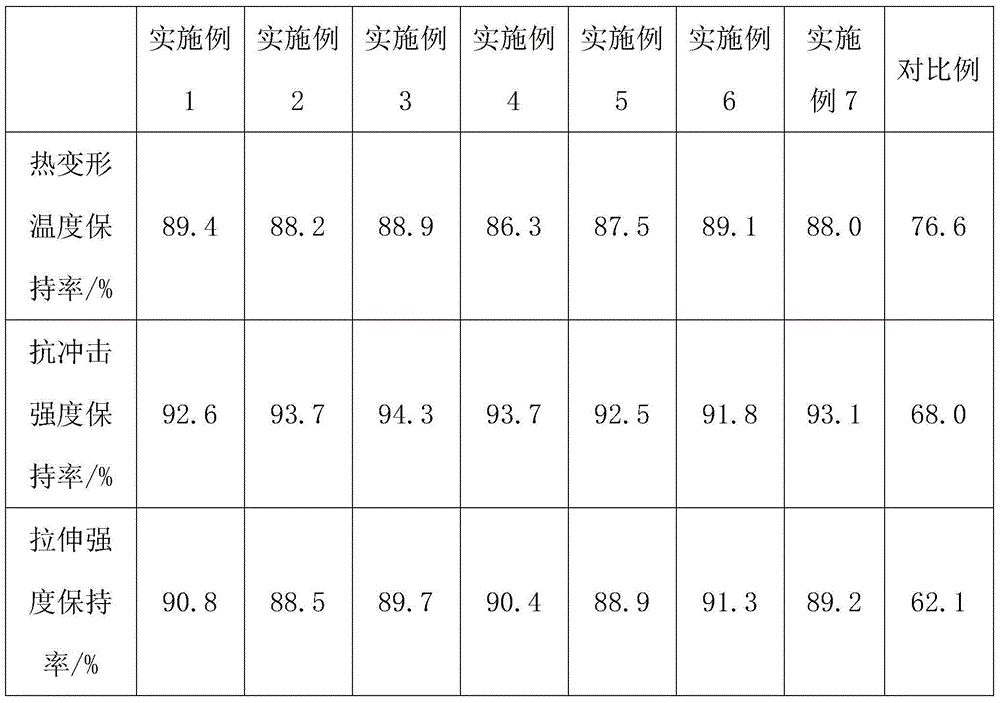

Examples

Embodiment 1

[0027] The PE sheath material for submarine cables consists of 100 parts by weight of HDPE, 9 parts of modified hemp fiber, 6 parts of modified magnesium oxide, 0.3 part of antioxidant CA, 9.4 parts of EVA, 2.5 parts of carbon black, calcium carbonate 3.8 parts, 0.1 part of calcium stearate, 0.1 part of titanate coupling agent.

[0028] The steps of its preparation method are as follows:

[0029] (1) After pulverizing the hemp fiber with a pulverizer, add a sodium hydroxide solution with a concentration of 2%, the solid-to-liquid ratio of the hemp fiber and the sodium hydroxide solution is 1:30, stir for 3 hours at 70 ° C, and use distilled water after discharging Wash until neutral, dry at 90°C for 2 hours to obtain alkalized fiber;

[0030] (2) After formic acid is dissolved in water and stirred evenly, a formic acid solution with a pH value of 4 is obtained, and the coupling agent A174 is added in the formic acid solution and stirred for 40 minutes to obtain a fiber modifi...

Embodiment 2

[0034] The PE sheath material for submarine cables consists of: 100 parts by weight of HDPE, 12 parts of modified hemp fiber, 9.5 parts of modified magnesium oxide, 0.2 part of antioxidant CA, 9 parts of EVA, 2.1 parts of carbon black, calcium carbonate 3.9 parts, 0.1 part of calcium stearate, 0.1 part of titanate coupling agent.

[0035] Its preparation method is the same as Example 1.

Embodiment 3

[0037] The PE sheath material for submarine cables consists of 100 parts by weight of HDPE, 11 parts of modified hemp fiber, 8 parts of modified magnesium oxide, 0.3 parts of antioxidant CA, 10 parts of EVA, 2.4 parts of carbon black, calcium carbonate 3.6 parts, 0.2 parts of calcium stearate, 0.1 parts of titanate coupling agent.

[0038] Its preparation method is the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com