Seawater corrosion and aging resistant rubber outsole and preparation method thereof

A technology resistant to seawater and raw rubber, which is applied in shoe soles, climate change adaptation, applications, etc., and can solve problems such as functional durability and durability that cannot meet demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Embodiment 1, the preparation of the outsole of anti-seawater corrosion aging

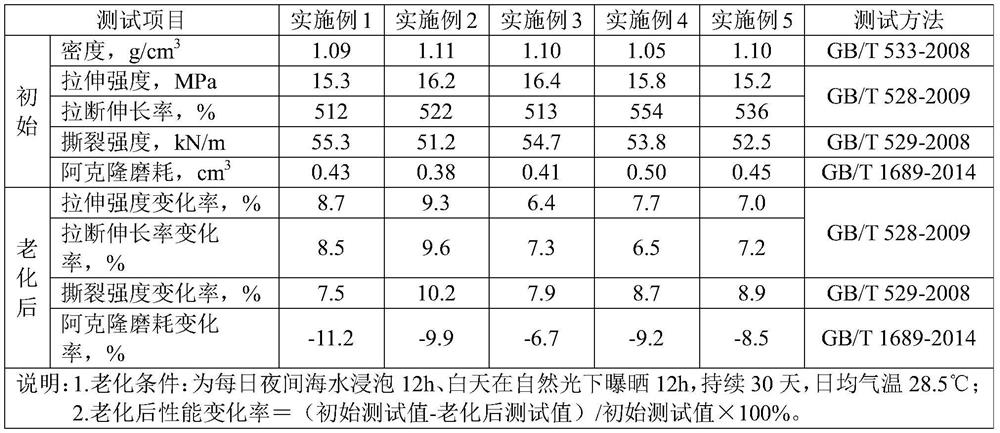

[0089] The formulations are shown in Table 1.

[0090] 1) Mix, vulcanize, and granulate the rubber according to the formula ratio, and set aside;

[0091] 2) Put the material evenly in the rubber mold, and press the middle plate of the mold for 10 seconds;

[0092] 3) Open the middle plate of the mold and cover it with 0.15mm thick high-temperature-resistant nylon fine-grain cloth, close the mold and press it, exhaust once every 10s, and close the mold for 5min after exhausting 3 times, the curing temperature is 160±5°C, the pressure 80MPa;

[0093] 4) Open the mold after vulcanization, gently tear off the nylon fine-grain cloth, and then take out the molded outsole.

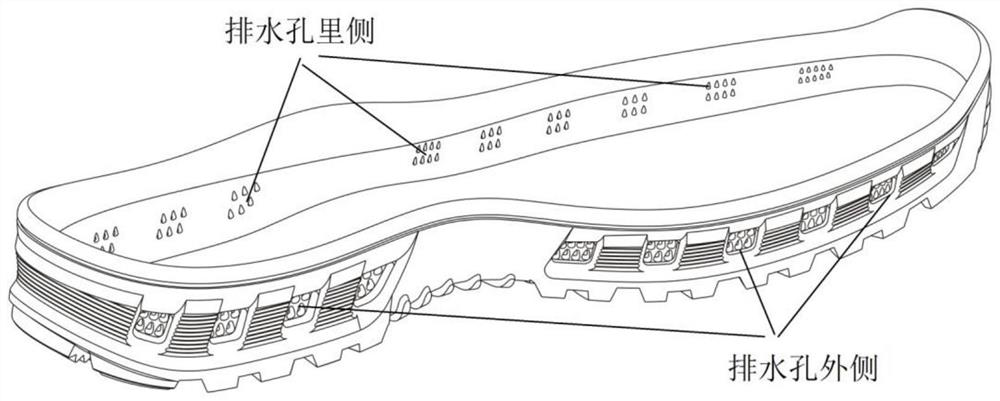

[0094] The properties of the rubber outsole semi-finished product thus obtained are shown in Table 2, and the structure is as follows figure 1 As shown, several drainage holes are formed on the side wall.

Embodiment 2

[0095] Embodiment 2, the preparation of the outsole of anti-seawater corrosion aging

[0096] The formulations are shown in Table 1.

[0097] 1) Mix, vulcanize, and granulate the rubber according to the formula ratio, and set aside;

[0098] 2) Put the material evenly in the rubber mold, and press the middle plate of the mold for 15 seconds;

[0099] 3) Open the middle plate of the mold and cover it with 0.15mm thick high-temperature-resistant nylon fine-grain cloth, close the mold and press it, exhaust once every 10s, and close the mold for 6 minutes after exhausting 3 times, the curing temperature is 160±5°C, 95MPa;

[0100] 4) Open the mold after vulcanization, gently tear off the fine nylon cloth, then take out the molded outsole, and form some drainage holes on the side wall.

[0101] The properties of the semifinished rubber outsole thus obtained are shown in Table 2.

Embodiment 3

[0102] Embodiment 3, the preparation of the outsole of anti-seawater corrosion aging

[0103] The formulations are shown in Table 1.

[0104] 1) Mix, vulcanize, and granulate the rubber according to the formula ratio, and set aside;

[0105] 2) Put the material evenly in the rubber mold, and press the middle plate of the mold for 12 seconds;

[0106] 3) Open the middle plate of the mold and cover it with 0.15mm thick high-temperature-resistant nylon fine-grain cloth, close the mold and press it, exhaust once every 10s, and then close the mold for 5.5min after exhausting for 3 times, the vulcanization temperature is 160±5°C, Pressure 90MPa;

[0107] 4) Open the mold after vulcanization, gently tear off the fine nylon cloth, then take out the molded outsole, and form some drainage holes on the side wall.

[0108] The properties of the semifinished rubber outsole thus obtained are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com