Sea water corrosion-resistant steel with low cost

A seawater-resistant and low-cost technology, applied in the field of steel, can solve the problems of increasing the production cost of corrosion-resistant steel and the difficulty of the production process, restricting the development of corrosion-resistant steel, and being difficult to satisfy, so as to be conducive to popularization and application and improve the corrosion resistance of seawater. , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

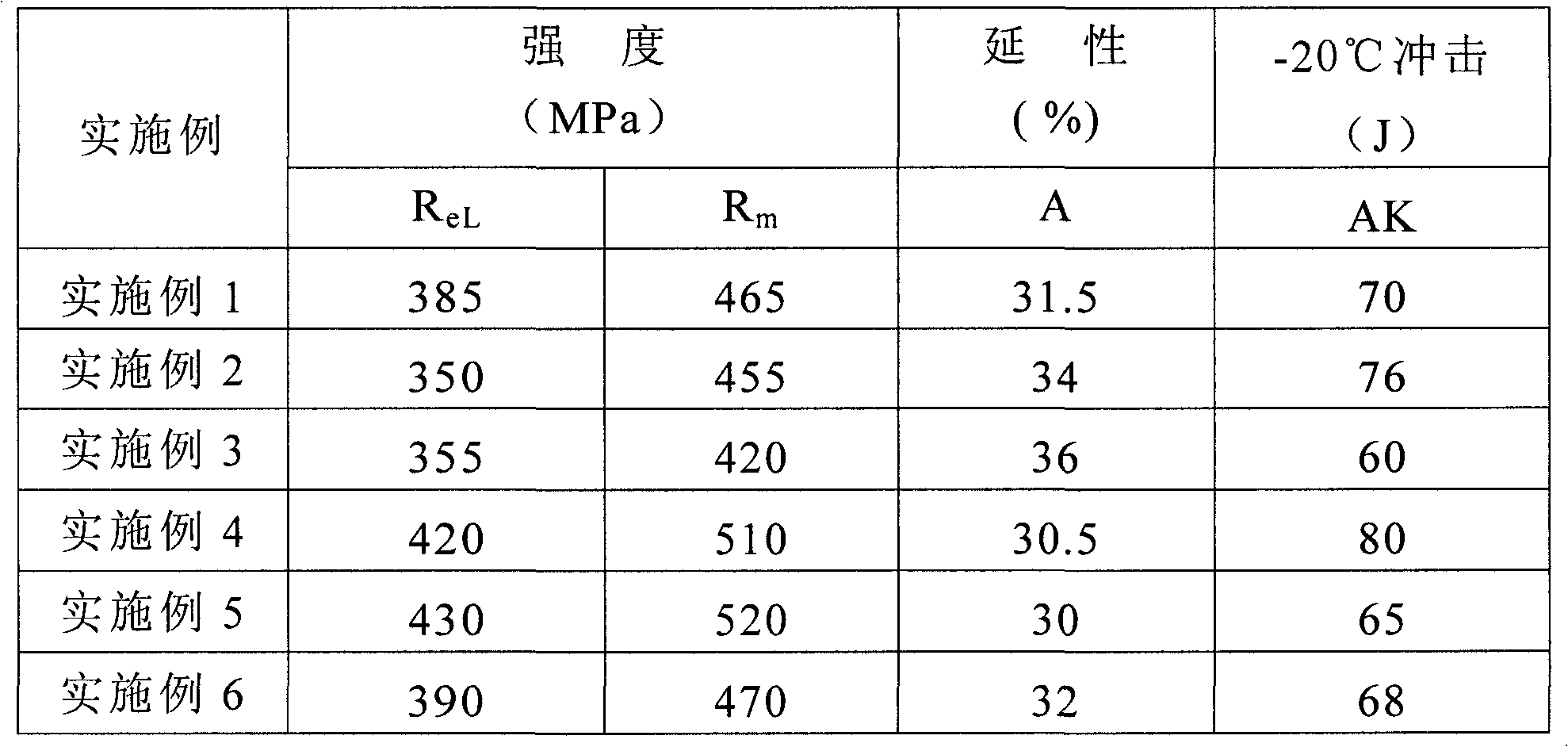

Examples

Embodiment 1

[0019] The chemical composition of low-cost seawater corrosion-resistant steel is calculated by weight percentage: C: 0.06, Si: 0.16, Mn: 0.70, P: 0.013, S: 0.016, Als: 0.070, O: 0.0050.

[0020] The steel was immersed in NaCl solution for 20 days, and the average corrosion rate was 4.58g / m 2 .h, the corrosion resistance is equivalent to 97.6% of MARINER steel.

Embodiment 2

[0022] The chemical composition of the low-cost seawater corrosion-resistant steel is C: 0.10, Si: 0.22, Mn: 0.75, P: 0.010, S: 0.011, Als: 0.039, O: 0.0040 by weight percentage.

[0023] In the 20-day weekly immersion test of the steel in NaCl solution, the average corrosion rate is 4.53g / m 2 .h, the corrosion resistance is equivalent to 98.7% of MARINER steel.

Embodiment 3

[0025] The chemical composition of low-cost seawater corrosion-resistant steel is C: 0.07, Si: 0.28, Mn: 0.50, P: 0.030, S: 0.019, Als: 0.004, O: 0.0061 by weight percentage.

[0026] The steel was immersed in NaCl solution for 20 days, and the average corrosion rate was 4.28g / m 2 .h, the corrosion resistance is equivalent to 104% of MARINER steel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com