Treatment method and treatment system apparatus for improving biodegradability of surface finishing liquid wastewater

A treatment method and a treatment system technology, applied in the field of improving the biochemical properties of skinning wastewater, can solve the problems of difficult biological treatment, high COD concentration, and poor biodegradability, and achieve low production and treatment costs, simple operation, and improved The effect of biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

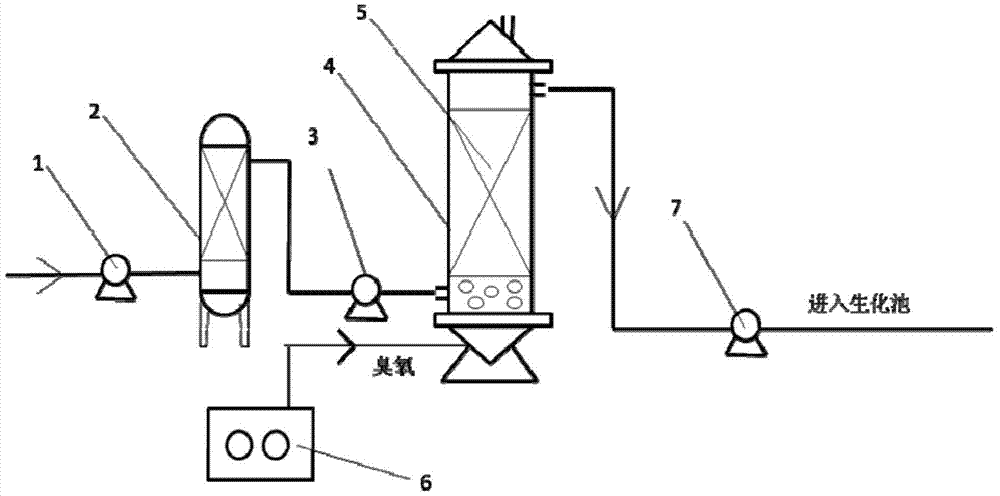

[0046] A treatment process system for improving the biochemical performance of skinning wastewater, including an inlet pump, a coarse sand filter, a first-stage lift pump, a contact reaction tower, a cordierite honeycomb ceramic loaded ferromanganese catalyst, an air source ozone generator, and an outlet water pump.

[0047] The COD of the water quality of the skinning wastewater is 9215 mg / L, the BOD is 630 mg / L, and the ratio of BOD / COD is 0.068.

[0048] The smoothing liquid waste water flows into the coarse sand filter through the water inlet pump, the filtration precision of the coarse sand filter is 55 microns, and the shell is made of carbon steel.

[0049] Then the skinning solution enters the contact reaction tower from the bottom through the primary lift pump, and the cordierite honeycomb ceramics loaded ferromanganese catalyst filler is placed in the contact reaction tower. The gas source of the ozone generator is the air source, and the ozone generated by the air ...

Embodiment 2

[0056] A treatment process system for improving the biochemical performance of skinning wastewater, including an inlet pump, a coarse sand filter, a first-stage lift pump, a contact reaction tower, a cordierite honeycomb ceramic loaded ferromanganese catalyst, an air source ozone generator, and an outlet water pump.

[0057] The COD of the water quality of the skinning wastewater is 11120 mg / L, the BOD is 680 mg / L, and the BOD / COD ratio is 0.061.

[0058] The smoothing wastewater flows into the coarse sand filter through the water inlet pump, and the main function of the coarse sand filter is to remove suspended solids and impurity particles in the wastewater. The coarse sand filter has a filtration rating of 55 microns and a carbon steel housing.

[0059] Then the skinning solution enters the contact reaction tower from the bottom through the primary lift pump, and the cordierite honeycomb ceramics loaded ferromanganese catalyst filler is placed in the contact reaction tower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com