Landfill leachate treatment agent and landfill leachate treatment method

A landfill leachate and treatment method technology, which is applied in the field of landfill leachate treatment agent and landfill leachate treatment, can solve the problems of stench, wide range of water quality changes, and difficult treatment, so as to reduce the content of organic matter, reduce the migration ability, Promotes the effect of sediment removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

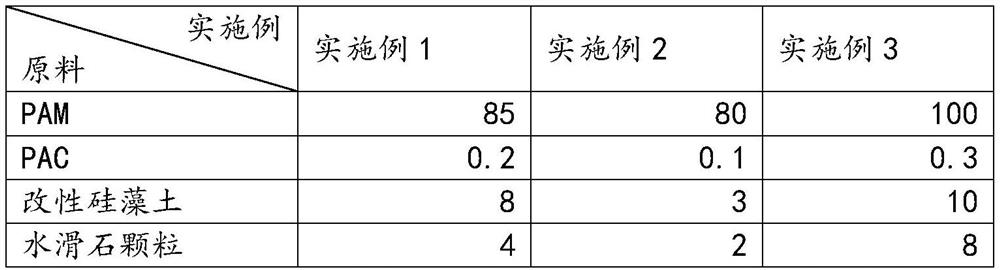

Examples

preparation example 1

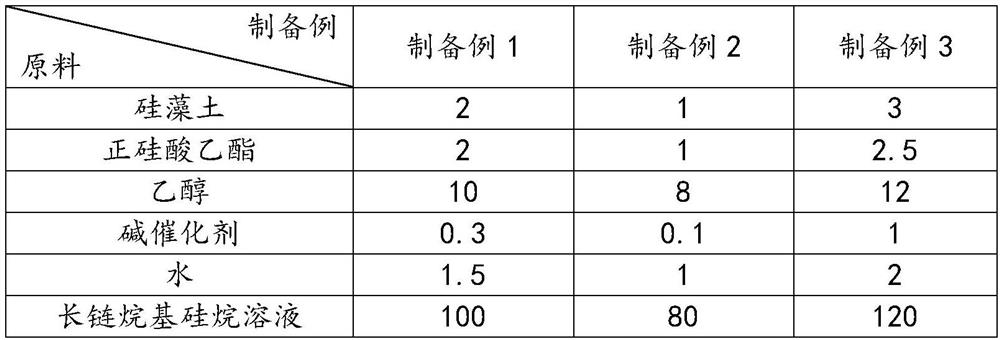

[0044] Preparation example 1, a modified diatomite, the selection of each raw material component is shown in Table 1, and it is prepared according to the following method:

[0045] S1-1: Mix tetraethyl orthosilicate, ethanol and water and stir evenly to obtain a mixed solution, soak diatomite with an average particle size of 100-200 mesh in the mixed solution, heat to 70°C and stir, and stir At the same time, dropwise add ammonia water (alkali catalyst) with a concentration of 10 wt% to the mixed solution, soak for 1 hour and filter to obtain particulate matter, and dry the particulate matter to constant weight to obtain pretreated diatomite;

[0046] S1-2: Add the pretreated diatomite to the toluene solution (long-chain alkylsilane solution) of 2wt% octadecyltrimethoxysilane, soak for 1h, filter and wash with ethanol, at 70°C Dry to constant weight to obtain modified diatomite.

preparation example 2

[0047] Preparation example 2, a modified diatomite, the selection of each raw material component is shown in Table 1, and it is prepared according to the following method:

[0048]S1-1: Mix tetraethyl orthosilicate, ethanol and water and stir evenly to obtain a mixed solution, soak diatomite with an average particle size of 200-300 meshes in the mixed solution, heat to 75°C and stir. At the same time, dropwise add a sodium hydroxide aqueous solution (alkaline catalyst) with a concentration of 5wt% to the mixed solution, soak for 0.5h and filter to obtain particulate matter, dry the particulate matter to constant weight, and obtain pretreated diatomite;

[0049] S1-2: adding the pretreated diatomite to the petroleum ether solution (long-chain alkylsilane solution) of octadecyltrichlorosilane with a concentration of 1.5wt%, soaking for 2h, cleaning with ethanol after filtering, and then washing at 80 Dry at ℃ to constant weight to obtain modified diatomite.

preparation example 3

[0050] Preparation Example 3, a modified diatomite, differs from Preparation Example 1 in that the selection of each raw material component is shown in Table 1.

[0051] Selection and consumption (kg) of each raw material in table 1, preparation examples 1~3

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com