System device for improving biodegradability of finishing liquid wastewater and treatment method

A fairing solution, biochemical technology, applied in the fields of metallurgical wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. Increases biodegradability, facilitates separation, increases efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The water quality pH of the finishing liquid wastewater was 7.9, the BOD5 was 345 mg / L, the BOD5 / CODcr was 0.07, and the suspended matter was 78 mg / L.

[0040] The fairing liquid waste water flows into the single-bag filter through the inlet pump, and the impurity particles in the fairing liquid are intercepted in the filter bag. The filtration precision of the single bag filter is 7 microns, the filter bag is made of polyester material, and the flow rate is 3m3 / h. After passing through the single-bag filter, the suspended solids of the fair-cleaning wastewater was 15 mg / L.

[0041] Then enter the ceramic membrane filter through the booster pump. The ceramic membrane filter is a precision ceramic filter material with a porous structure, which is sintered at high temperature such as alumina. The porous support layer, the filter layer and the microporous membrane layer are distributed asymmetrically. The filtration precision of the ceramic membrane filter is 0.5 microns...

Embodiment 2

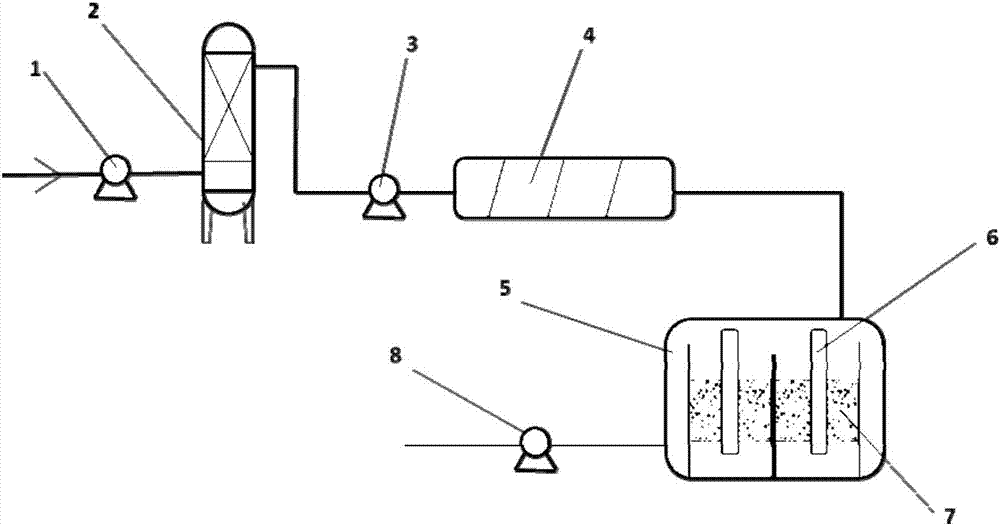

[0047] A treatment process system for improving biodegradability in fairing liquid wastewater, including an inlet pump, a single-bag filter, a booster pump, a ceramic filter, an ultraviolet photochemical reactor, a parallel UV lamp tube, and quartz sand-loaded titanium vanadium light Catalyst, drain pump.

[0048] The water quality pH of the finishing liquid wastewater was 8.4, the BOD5 was 402 mg / L, the BOD5 / CODcr was 0.13, and the suspended matter was 111 mg / L.

[0049] The fairing liquid waste water flows into the single-bag filter through the inlet pump, and the impurity particles in the fairing liquid are intercepted in the filter bag. The filtration precision of the single bag filter is 7 microns, the filter bag is made of polyester material, and the flow rate is 8m3 / h. After passing through the single-bag filter, the suspended solids of the finishing wastewater was 16 mg / L.

[0050] Then enter the ceramic membrane filter through the booster pump. The ceramic membrane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com