Processing system and processing method of strong brine from reverse osmosis of coking

A processing system and processing method technology are applied in the field of processing systems for coking reverse osmosis concentrated brine, and can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

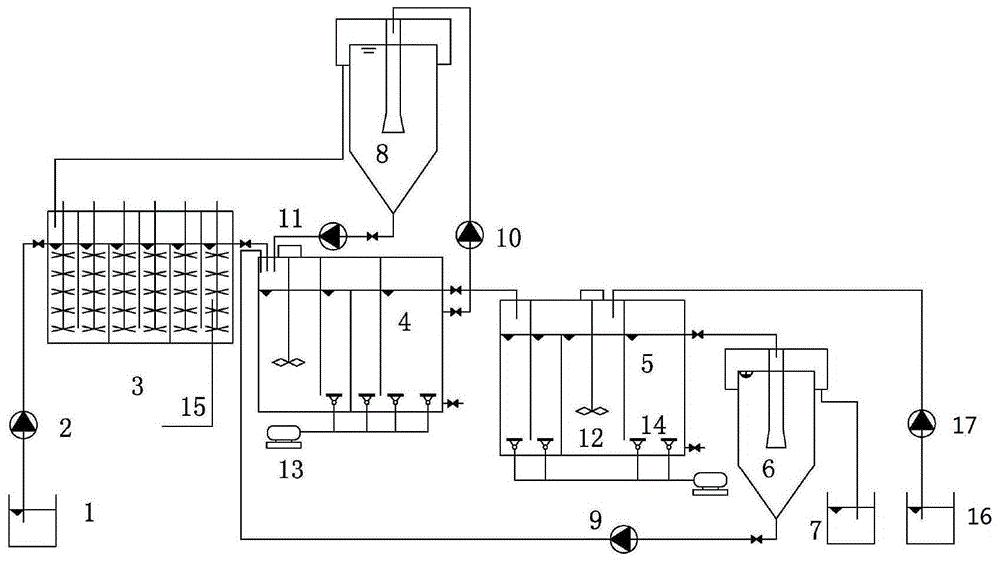

[0038] A coking reverse osmosis concentrated brine treatment system, including a water inlet tank, a water inlet pump, a packing tank, a large aerobic tank, a small aerobic tank, a biological sedimentation tank, a water outlet tank, a nitrification sedimentation tank, a sludge return pump, and a nitrification sedimentation tank inlet Water pumps, nitrification sedimentation tank sludge pumps, mechanical mixers, air pumps, aeration sand heads, combined packing, sludge discharge valves, carbon source solvent pools and metering pumps.

[0039] The water quality conductivity of the reverse osmosis concentrated brine of the coking wastewater is 11000-19000 μs / cm, the chloride ion is 1500-5000 mg / L, the sulfate ion is 300-700 mg / L, the pH is 6-9, and the total nitrogen is 60-170 mg / L. L, nitrate nitrogen is 30~140mg / L, ammonia nitrogen is 25~75mg / L, COD is 40~520mg / L, BOD is 20~60mg / L.

[0040] The coking reverse osmosis concentrated brine flows into the water inlet tank through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com