Ecological treatment system and method for cold-rolling reverse osmosis strong brine

A technology for ecological treatment and concentrated brine, applied in metallurgical wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve environmental pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

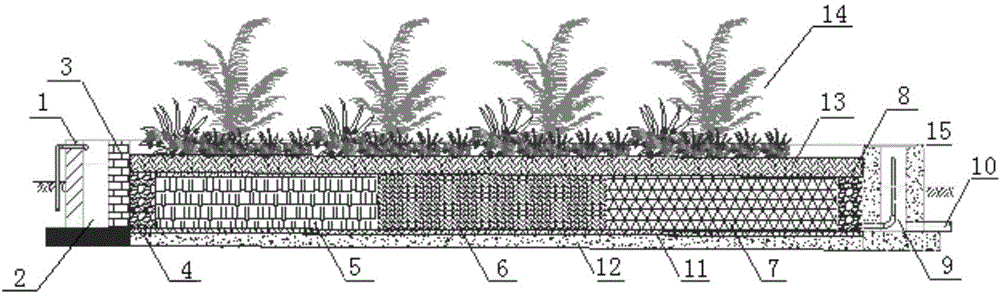

Embodiment 1

[0053] The water quality of the cold rolling wastewater reverse osmosis concentrated brine: conductivity 6800μs / cm, COD 55mg / L, pH 7.51, turbidity 16NTU, ammonia nitrogen 5.1mg / L, total nitrogen 11.3mg / L, total phosphorus 0.4mg / L L, oil 4.87mg / L, chromium 0.01mg / L, iron 0.7mg / L, Zn 0.2mg / L, Ni 0.2mg / L.

[0054] The cold-rolled reverse osmosis concentrated brine enters the water inlet tank through the water inlet pipe, and a triangular weir is designed on the water inlet tank, and the water inlet flow is adjusted by controlling the constant water level of the water distribution tank. The brine in the water inlet tank enters the water inlet gravel rectification area through the water distribution partition. The opening ratio of the water distribution partition is 35%, and the hole diameter is 40mm. The function of the influent gravel rectification area is that the energy of the waste water flow is eliminated in the inflow rectification area, so that the waste water flow enters ...

Embodiment 2

[0068] The water quality of the cold rolling wastewater reverse osmosis concentrated brine: conductivity 7600μs / cm, COD 58mg / L, pH 7.91, turbidity 18NTU, ammonia nitrogen 5.1mg / L, total nitrogen 11.3mg / L, total phosphorus 0.4mg / L L, oil 4.87mg / L, chromium 0.02mg / L, iron 0.9mg / L, Zn 0.3mg / L, Ni 0.3mg / L.

[0069] The cold-rolled reverse osmosis concentrated brine enters the water inlet tank through the water inlet pipe, and a triangular weir is designed on the water inlet tank, and the water inlet flow is adjusted by controlling the constant water level of the water distribution tank. The brine in the water inlet tank enters the water inlet gravel rectification area through the water distribution partition. The opening rate of the water distribution partition is 40%, and the hole diameter is 42mm. The function of the influent gravel rectification area is that the energy of the waste water flow is eliminated in the inflow rectification area, so that the waste water flow enters t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com