Method for preparing cold ramming paste for electrolytic aluminum

A technology for cold pounding and electrolysis of aluminum, applied in the field of aluminum electrolysis, can solve problems such as physical injury of construction workers and environmental pollution, and achieve the effects of reducing labor intensity, simple process, and improving physical and chemical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

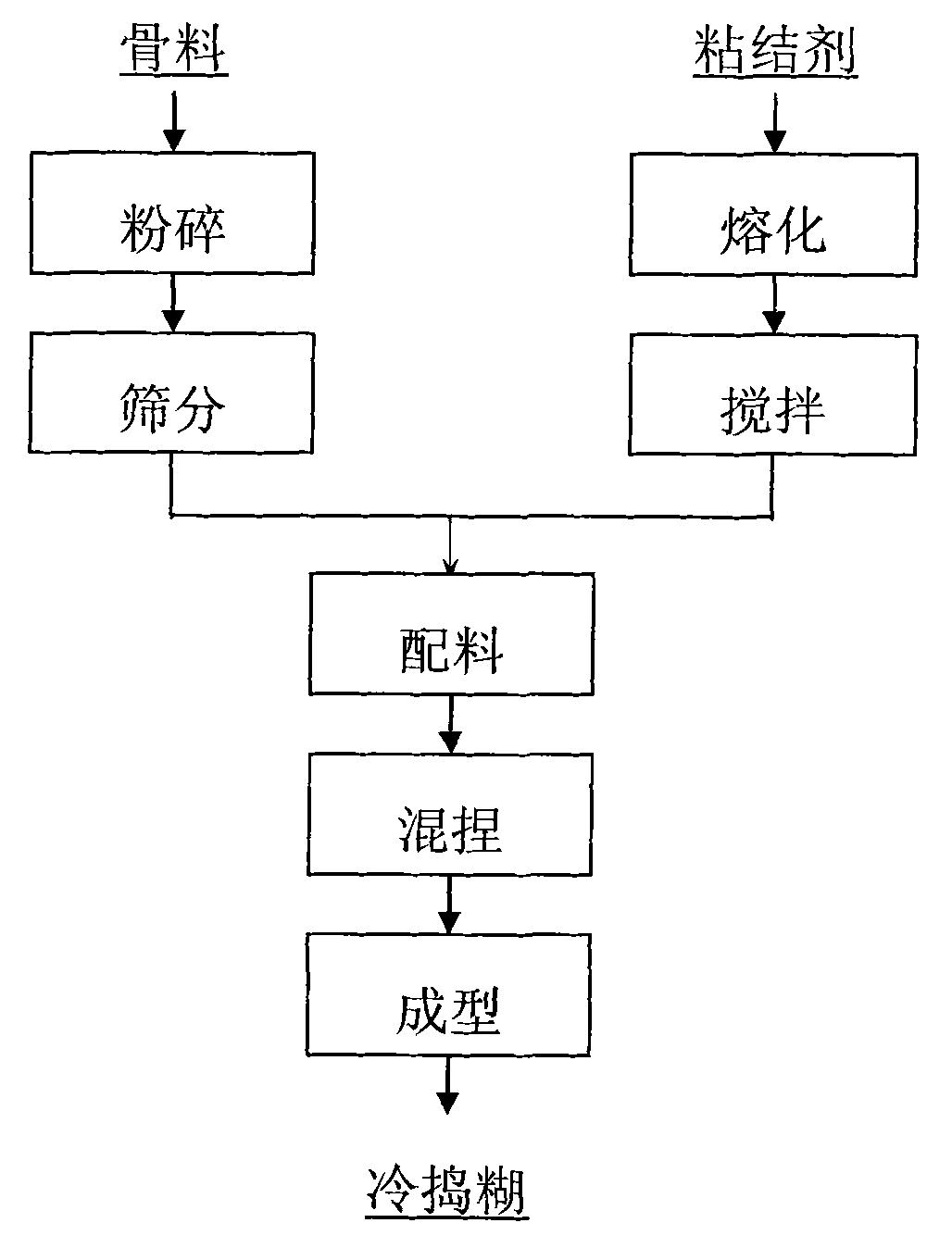

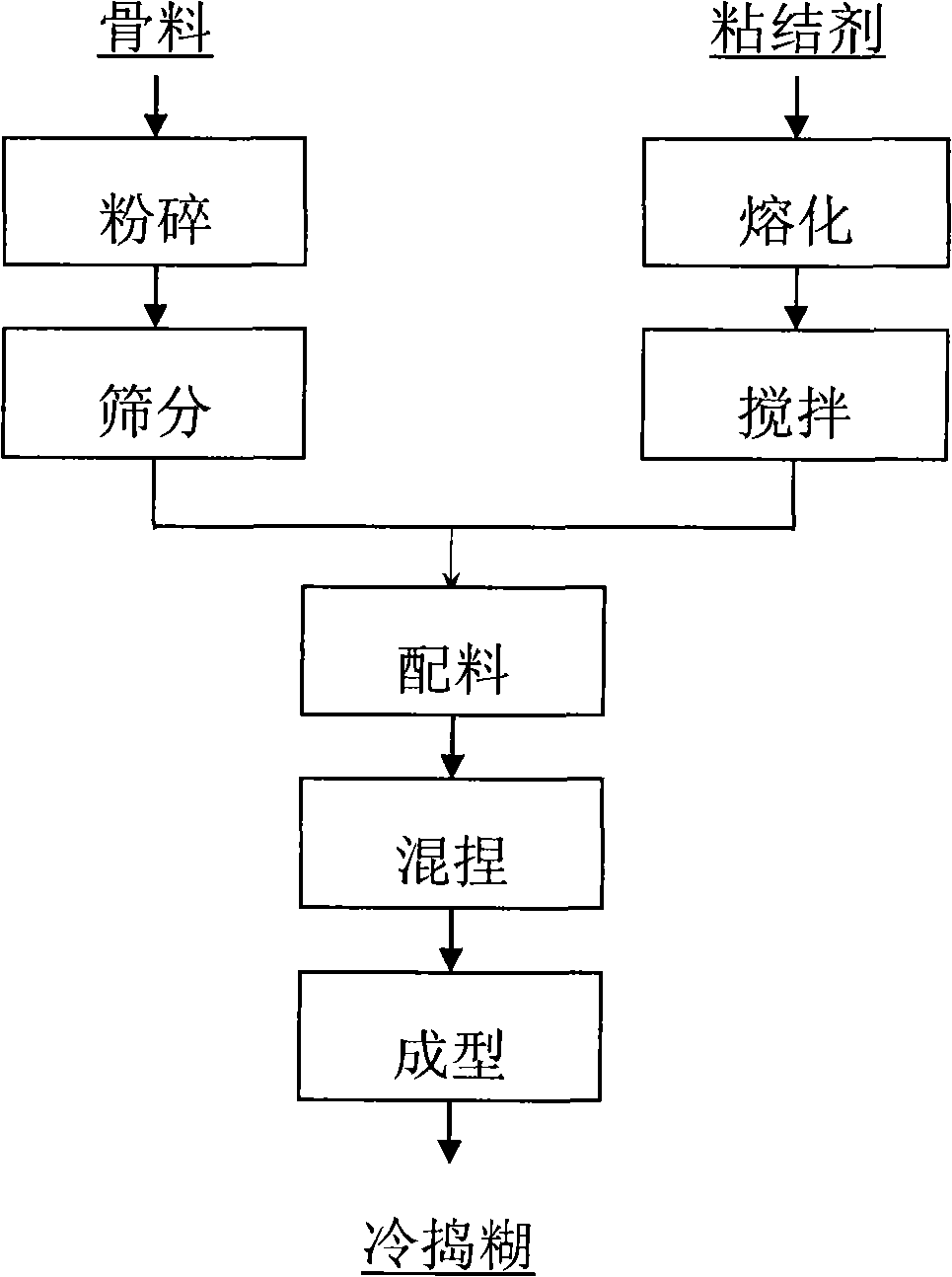

Method used

Image

Examples

Embodiment 1

[0016] Electric calcined anthracite with a carbon content of 95wt% is used as the aggregate raw material. The raw materials are crushed by a crusher, ball milled by a ball mill, and the aggregate is screened by a sieving machine to obtain an aggregate powder with a particle size of 150 μm; according to a weight ratio of 1:1:1, phenolic resin, furfural resin, and asphalt are weighed as viscose. The binder is melted. The electric calcined anthracite aggregate and the melted binder were sequentially introduced into a kneader according to a weight ratio of 5:1, and mixed and stirred for 1 hour, and the kneading temperature was 90°C. Then the kneaded material is poured into a molding machine for molding treatment to obtain a cold rammed product of a specified size.

[0017] Implementation results: the resistivity of the cold rammed product is 65μΩ·m, the compressive strength is 25MPa, and the bulk density is 1.5g / cm 3 . The product is capable of tamping operations at room temper...

Embodiment 2

[0019] Petroleum coke with a carbon content of 98wt% is used as the aggregate raw material. The raw materials are crushed by a crusher, ball milled by a ball mill, and the aggregate is screened by a sieving machine to obtain aggregate powder with a particle size of 250 μm; epoxy resin, furan resin, and coal tar are weighed according to a weight ratio of 1:2:1 Melted as a binder. The petroleum coke aggregate and the melted binder were successively introduced into the kneader according to the weight ratio of 8:1 and mixed and stirred for 5 hours, and the kneading temperature was 120°C. Then the kneaded material is poured into a molding machine for molding treatment to obtain a cold rammed product of a specified size.

[0020] Implementation results: the resistivity of the cold rammed product is 55μΩ·m, the compressive strength is 35MPa, and the bulk density is 1.8g / cm 3 . The product is capable of tamping operations at room temperature. All indicators can meet the requiremen...

Embodiment 3

[0022] A mixture of high-carbon graphite with a carbon content of 97 wt% and metallurgical coke is used as the aggregate raw material, and the weight ratio of the two is 2:1. The raw materials were crushed by a crusher, ball milled by a ball mill, and the aggregate was sieved by a sieving machine to obtain an aggregate powder with a particle size of 250 μm; according to a weight ratio of 2:1:1, phenolic resin, asphalt, and anthracene oil were weighed as viscous The binder is melted. The mixed aggregate and the melted binder are successively introduced into the kneader according to the weight ratio of 15:1 and mixed and stirred for 8 hours, and the kneading temperature is 180°C. Then the kneaded material is poured into a molding machine for molding treatment to obtain a cold rammed product of a specified size.

[0023] Implementation results: the resistivity of the cold rammed product is 57μΩ·m, the compressive strength is 32MPa, and the bulk density is 1.6g / cm 3 . The produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com