Self-elevating MOPU economical power system

A power system and economical technology, applied in the field of offshore marine engineering, can solve the problems of unsuitable construction cost and increase project construction cost, etc., and achieve the effects of reducing production and processing costs, saving space and layout, and increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

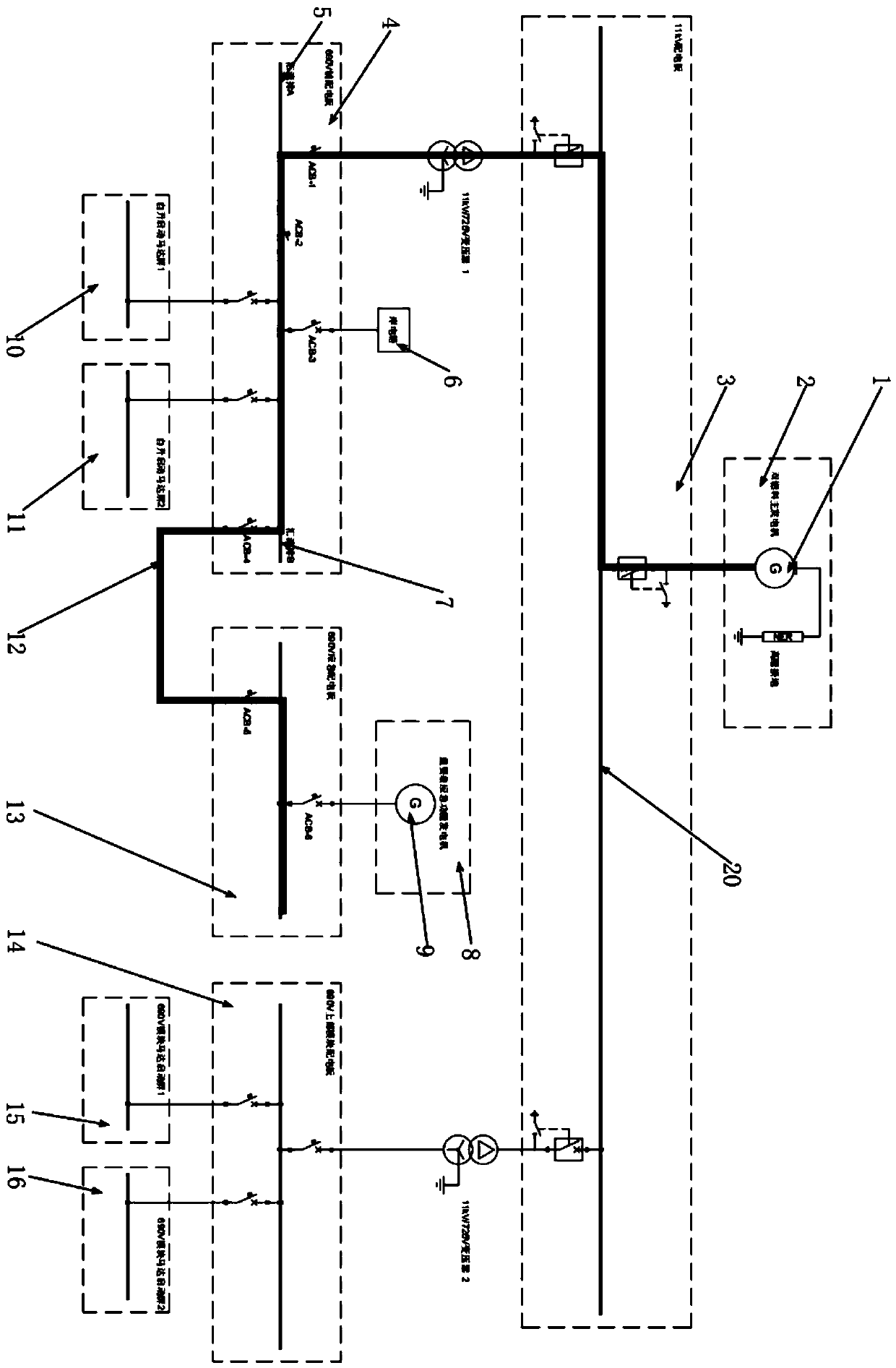

[0028] Embodiment 1: as attached figure 1 As shown, the platform is powered by the dual-fuel main generator 1 using the L-shaped power supply mode 12 to supply power to all equipment on the platform. The neutral point of the dual-fuel main generator 1 is grounded with high resistance. The 11KV electric energy is transmitted to the 690V marine auxiliary switchboard 4 through the 11KV / 725V transformer 1, and another 11KV / 725V transformer 2 is sent to the 690V upper module switchboard 14.

[0029] The 690V marine auxiliary switchboard 4 realizes power chain energy supply through the following switches: incoming line switch ACB-1, confluence isolating switch ACB-2, shore power incoming line switch ACB-3, and contact switch ACB-4 (used for and emergency distribution board connection).

[0030] The 690V emergency switchboard 13 realizes the power supply chain function through the following switches: contact switch ACB-5 (used to connect with the marine auxiliary switchboard), gener...

Embodiment 2

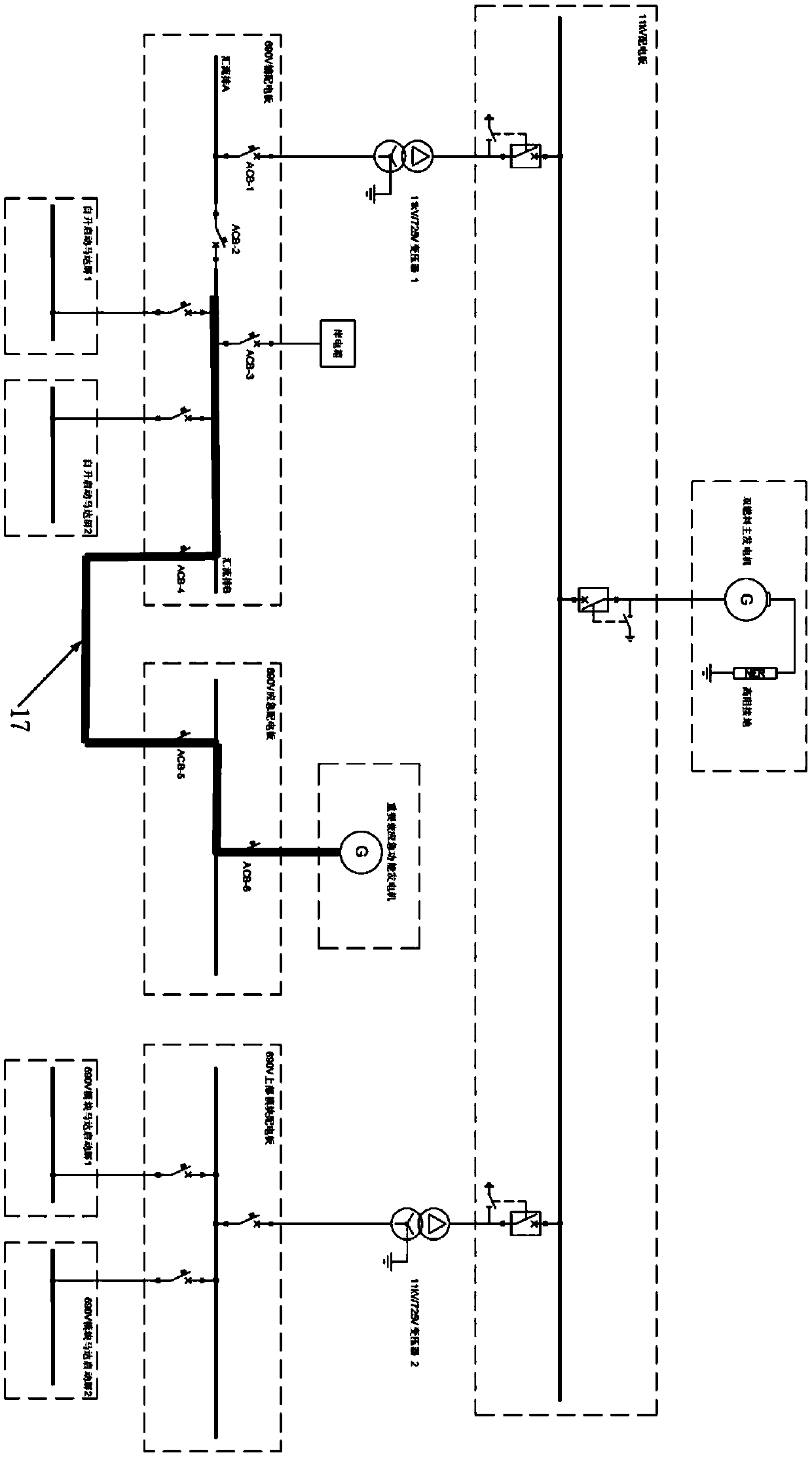

[0032] Embodiment 2: as attached figure 2 As shown, the power supply of the platform uses the reverse power supply mode 17 through the important and emergency function generator 9 to meet the power supply requirements of the platform's main important living equipment and platform self-elevating equipment. During this process, the power management system of the intelligent power station on the platform monitors the power failure of the main busbar, and the power management system disengages the incoming switch ACB-1, and the busbar A5 is automatically isolated by the busbar isolation switch ACB-2. The incoming line switch ACB-3 allows manual parallel closing, and the important and emergency function generator 9 starts automatically within 45 seconds. The important and emergency function generator 9 power supply switch ACB-6 automatically closes for reverse power supply. The switch ACB-5 and the contact switch ACB-4 are sent to the bus bar B7, and the 690V emergency distributio...

Embodiment 3

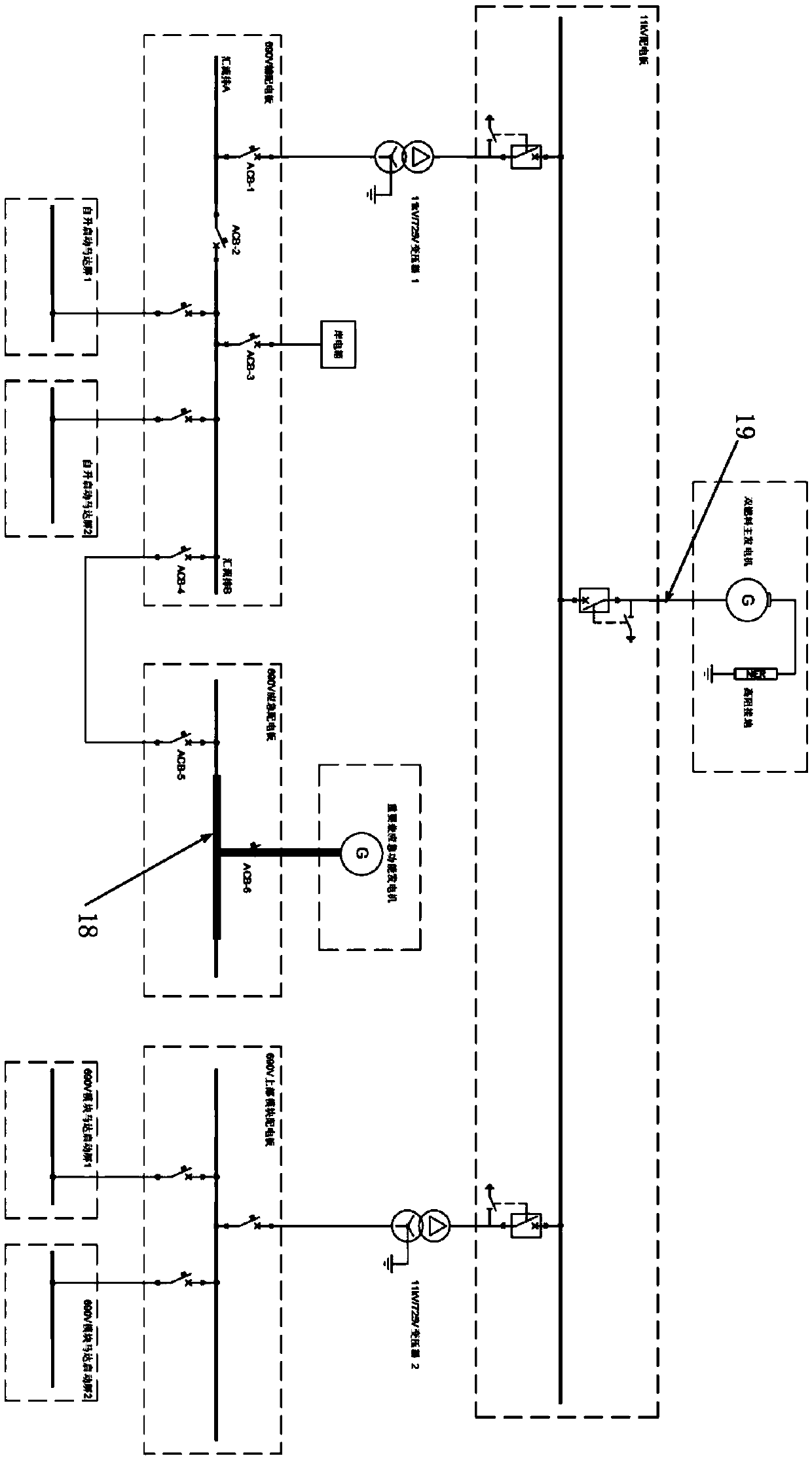

[0034] Embodiment 3: as attached image 3 As shown, when an emergency condition occurs on the platform, the emergency shutdown system sends an instruction signal and the contact switch ACB-5 will be automatically disengaged, the 690V emergency switchboard 13 will run in isolation, and the important and emergency function generator 9 will be within 45 seconds. The starter switches to emergency mode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com