Combined fixture for cast crossbeams

A beam and fixture technology, applied in the direction of manufacturing tools, clamping, support, etc., can solve the problems of difficult processing, increase production and manufacturing costs, and many handling times, and achieve the effect of reducing production and handling costs, ensuring angular accuracy, and reducing processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention.

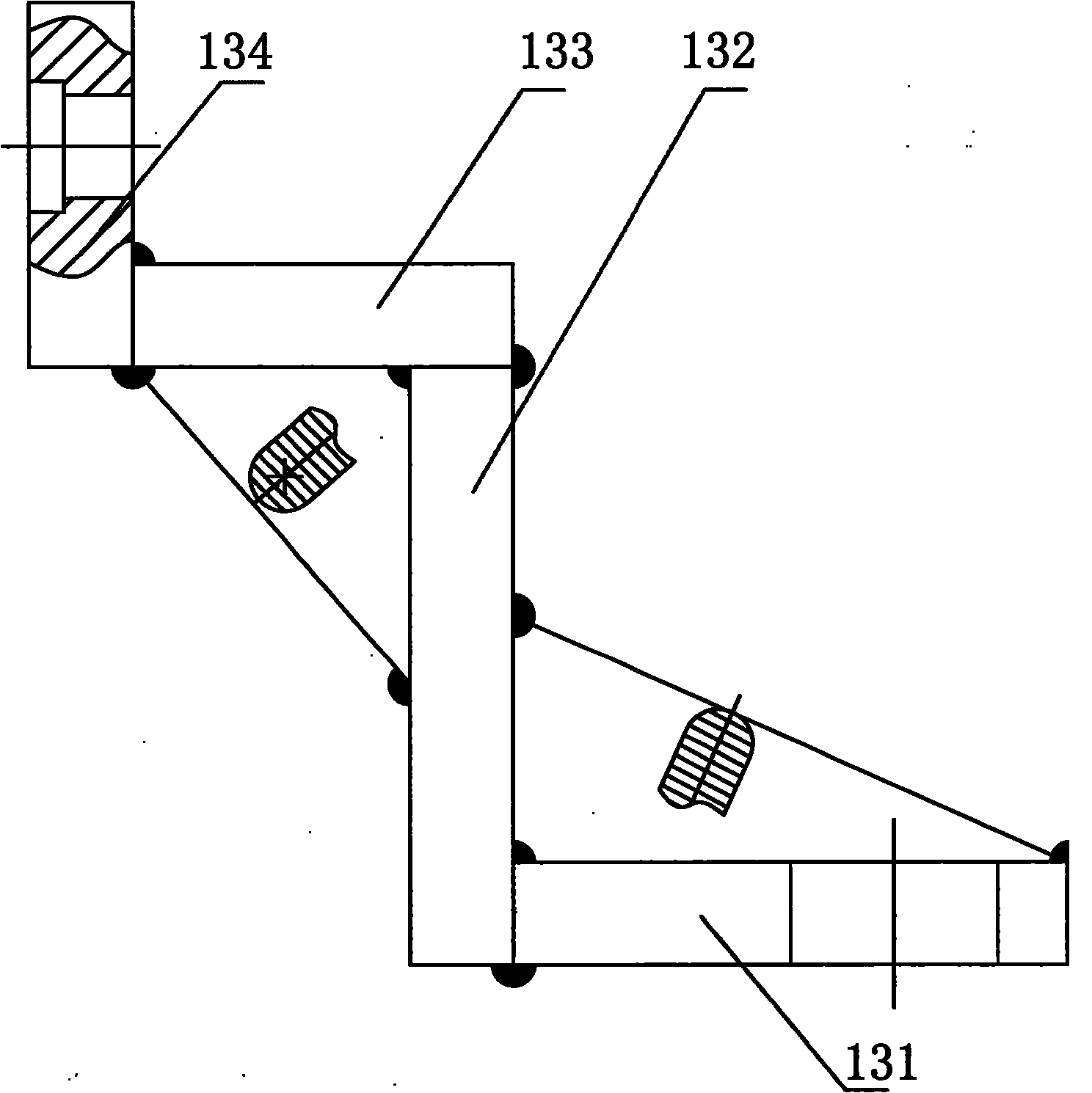

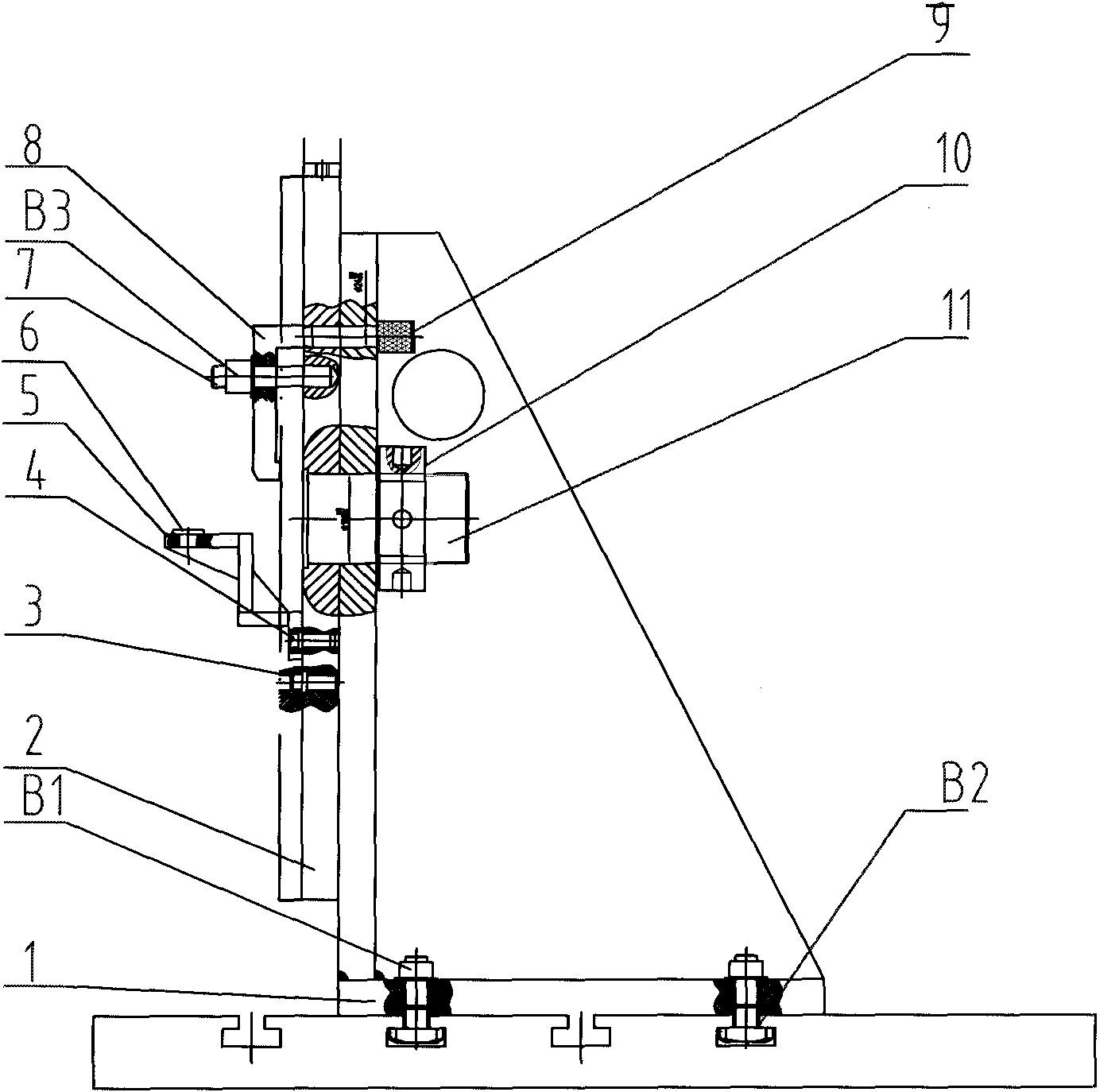

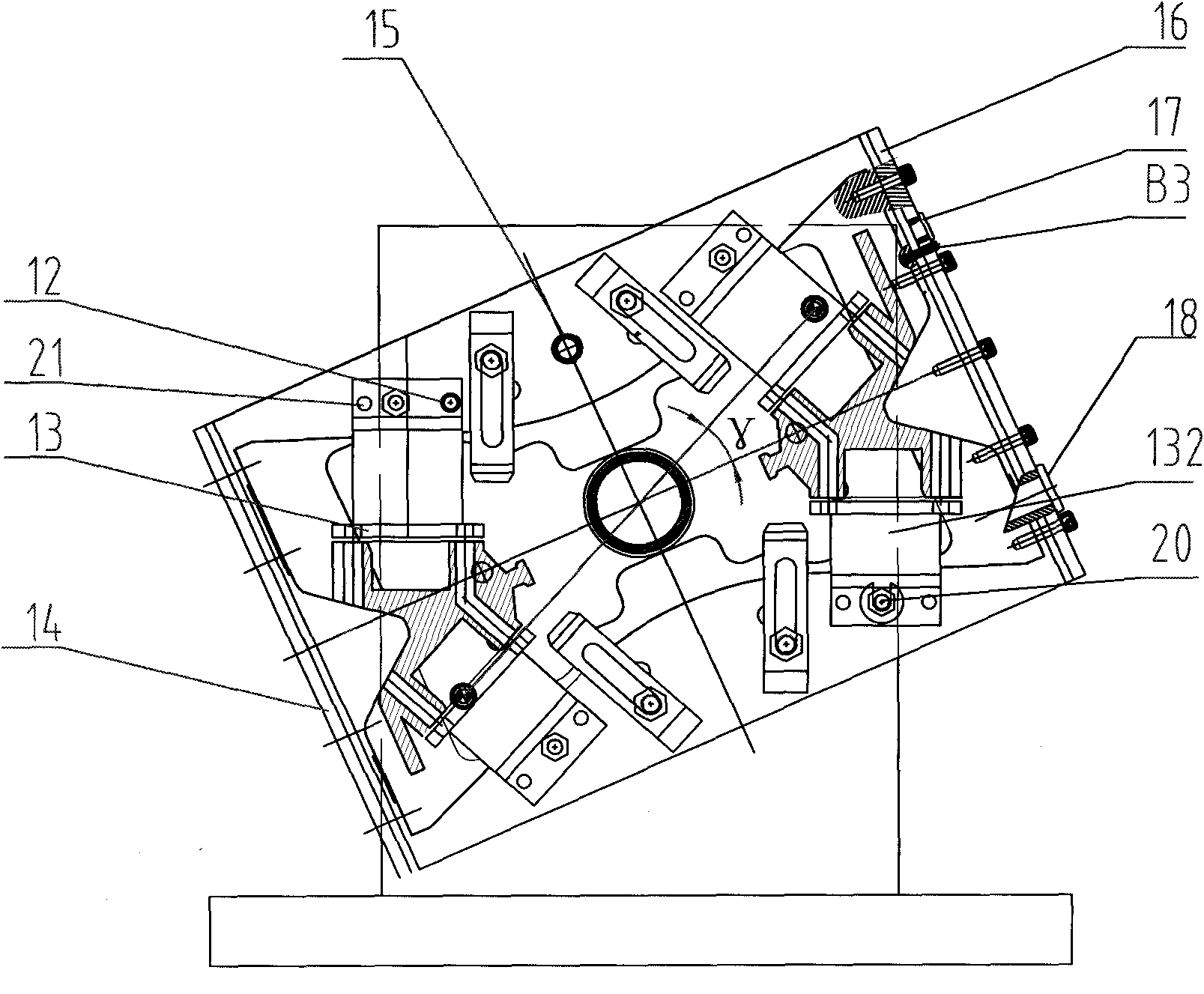

[0032] Such as figure 1 , 2 A casting crossbeam composite fixture is shown, comprising a fixed seat 1, a rotary plate 2, an end hole drilling template 14, at least two inclined hole drilling templates 13 and several clamping parts, and the fixed seat 1 has a The installation surface 1-1 and a fixed surface 1-2 perpendicular to the installation surface 1-1; the rotary plate 2 is rotatably mounted on the fixed surface 1-2 through the connecting shaft 11 and positioned by the shaft with the bushing 15; The two end hole drilling templates 14 are fixed on the two sides of the rotary plate 2, and the surface is provided with mold holes corresponding to the holes to be processed on both sides of the cast beam, and are positioned by the pin B3; the inclined hole d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com