Chlorine containing high-concentration NOX waste gas treatment method

A waste gas treatment and high-concentration technology, which is applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of reducing production costs, tail gas emissions that cannot meet standards, and oxidation efficiency that decreases over time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] A catalyst roasting process produces chlorine-containing high-concentration NOx exhaust gas: the exhaust gas flow rate is 3200Nm 3 / H, NOx concentration is 12500mg / m 3 , Cl 2 The concentration is 2144mg / m 3 , the rest is air, the oxygen content is about 20v%; the exhaust gas temperature is 200°C;

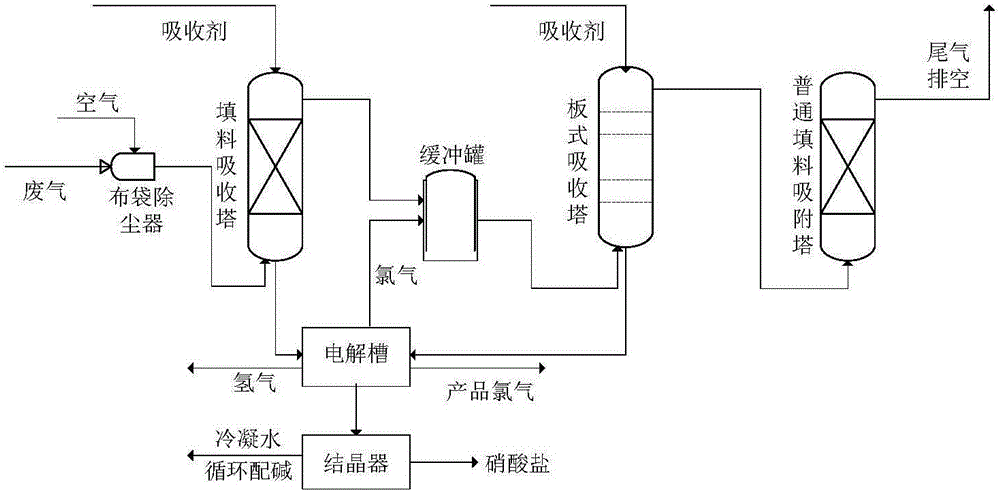

[0066] After the gas is dedusted by the bag 208, the dust concentration at the outlet is 20mg / m 3 . Add a stream of fresh air, the gas flow rate is 3200Nm 3 / H, after the two are mixed, the gas temperature is reduced to 100°C, and it is introduced from the bottom of the packed absorption tower through the induced draft fan. The packed absorption tower is 3-stage packing, and the semiconductor packing is TiO 2 , the wavelength of ultraviolet light is 300-350nm, the absorbent is 20wt% NaOH solution, the temperature of the absorbent is guaranteed to be 45-50°C through steam tracing, the absorbent is in countercurrent contact with the exhaust gas, the effective contact time o...

Embodiment 2

[0070] A catalyst roasting process produces chlorine-containing high-concentration NOx exhaust gas: the exhaust gas flow rate is 15000Nm 3 / H, NOx concentration is 5000mg / m 3 , Cl 2 The concentration is 500mg / m 3 , the rest is air, the oxygen content is about 20v%; the exhaust gas temperature is 100°C;

[0071] After the gas passes through the bag dust removal, the dust concentration at the outlet is detected to be 0. No air is introduced into it, and it is introduced from the bottom of the packed absorption tower through the induced draft fan. The packed absorption tower is 2-stage packing, and the semiconductor packing is TiO 2 , the wavelength of ultraviolet light is 350-400nm, the absorbent is 10wt% NaOH solution, the temperature of the absorbent is guaranteed to be 40-45°C through steam tracing, the absorbent is in countercurrent contact with the exhaust gas, the effective contact time of the gas is 5S, and the gas-liquid ratio is 8:1. The absorption liquid is recycl...

Embodiment 3

[0073] A catalyst roasting process produces chlorine-containing high-concentration NOx exhaust gas: the exhaust gas flow rate is 1500Nm 3 / H, NOx concentration is 25000mg / m 3 , Cl 2 The concentration is 3500mg / m 3 , the oxygen content is 15v%; the exhaust gas temperature is 100°C;

[0074] After the gas passes through the bag dust removal, the dust concentration at the outlet is detected to be 10mg / m 3 . A stream of fresh air is added through the induced draft fan, and the air flow rate is 750Nm 3 / H, the oxygen concentration in the exhaust gas is 19v% at this time, the two gases are mixed in the buffer tank, the gas temperature after mixing is 67°C, the gas is introduced from the bottom of the packed absorption tower, the packed absorption tower is 4-stage packing, and the semiconductor packing is TiO 2 , the wavelength of ultraviolet light is 250-300nm, and the absorber is

[0075] 15wt% NaOH solution, the temperature of the absorbing liquid is guaranteed to be 45-50°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com