A method for comprehensively treating vanadium-containing slag and titanium dioxide waste acid

A technology of vanadium-containing slag and titanium dioxide waste acid, which is applied in the improvement of process efficiency and cement production, can solve the problems of high market share, high cost of purchasing raw materials, and high energy consumption in production, so as to reduce production and processing costs, reduce The effect of ecological pollution damage and waste water treatment cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

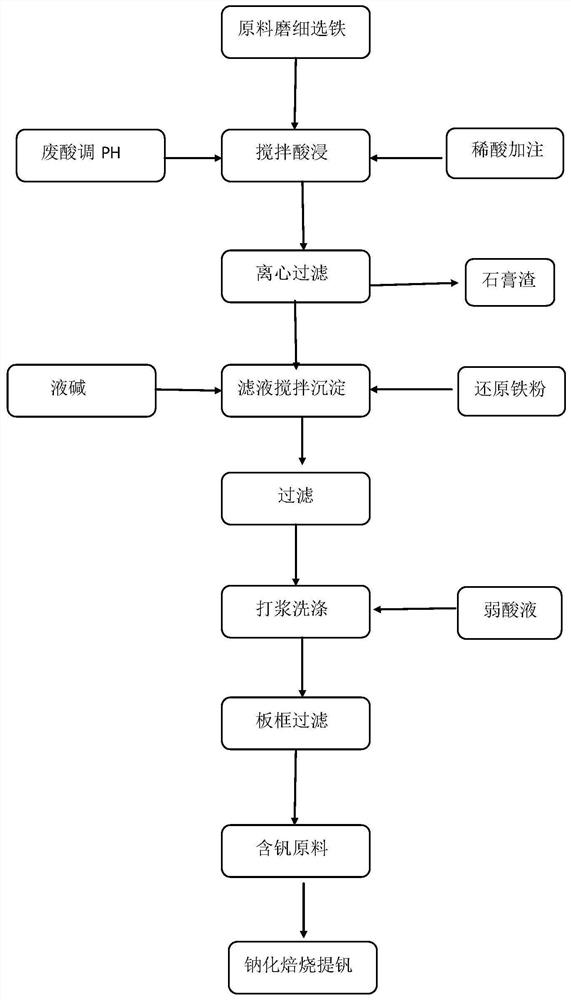

[0036] A method for comprehensively processing vanadium-containing slag and titanium dioxide waste acid, comprising the following steps:

[0037] (1) After crushing and grinding the vanadium-containing slag, pass it through a 120-mesh screen, and magnetically select 6% bright iron. Weigh 20kg of slag powder for later use; inject 60L of dilute acid into the reaction tank, gradually add 20kg of slag powder under the stirring condition of 300r / min rotating speed, and finish adding after about 5 minutes, at this time, a premixed solution is obtained, and its temperature is 42 ° C, pH The value is 3.3;

[0038] (2) Slowly add waste acid to the premix to adjust the pH to about 1.8, the reaction time is 45min, the reaction temperature is 50°C, and the waste acid is consumed 47L; Acid high-sulfur gray-white gypsum slag and 100L vanadium-containing solution; gypsum slag SO 3 Greater than 35%, moisture 22%, V 2 O 5 The content is 0.20%, the dry weight is 23.2KG, and the vanadium lea...

Embodiment 2

[0048] A method for comprehensively processing vanadium-containing slag and titanium dioxide waste acid, comprising the following steps:

[0049] (1) After crushing and grinding the vanadium-containing slag, pass through a 120-mesh sieve, and magnetically select open iron to obtain slag powder; according to the ratio of liquid-solid ratio of 1:4, add 20kg of slag powder to 80L of dilute acid, and stir Mixing, the rotating speed is 200r / min, after the addition is completed, a premixed solution is obtained, the temperature of which is 45 °C, and the pH value is 2.8;

[0050] (2) Slowly add waste acid to the premix to adjust pH to about 1.7, the reaction time is 50min, and the reaction temperature is 52°C; after the reaction is completed, solid-liquid separation is carried out with a negative pressure centrifuge to obtain 31.58kg of water-acid high-sulfur gray-white gypsum Slag and 118L vanadium-containing solution; SO in gypsum slag 3 40%, moisture 23%, V 2 O 5 The content is...

Embodiment 3

[0054] A method for comprehensively processing vanadium-containing slag and titanium dioxide waste acid, comprising the following steps:

[0055] (1) After crushing and grinding the vanadium-containing slag, pass through a 120-mesh sieve, and magnetically select open iron to obtain slag powder; according to the ratio of liquid-solid ratio of 1:2.5, 20kg of slag powder is added to 50L of dilute acid, and stirred Mixing, the rotating speed is 300r / min, after the addition is completed, a premix is obtained, the temperature of which is 50 °C, and the pH value is 3.5;

[0056] (2) Slowly add waste acid to the premix to adjust pH to 1.6, the reaction time is 60min, the reaction temperature is 55°C, and the waste acid consumption is 58L; after the reaction is completed, use a negative pressure centrifuge for solid-liquid separation to obtain 32.47KG of water Acid high-sulfur off-white gypsum slag and vanadium-containing solution; SO in gypsum slag 3 43%, moisture 23%, V 2 O 5 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com