Preparation method of normal temperature curing biomass pyrolysis oil-based structure adhesive

A biomass pyrolysis oil and structural adhesive technology, applied in the direction of in-line phenolic epoxy resin adhesive, can solve problems such as difficulty in adapting to the rapid development of wood structural materials, and achieve widening high-value utilization pathways , Improve wettability, easy to wet the wood surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

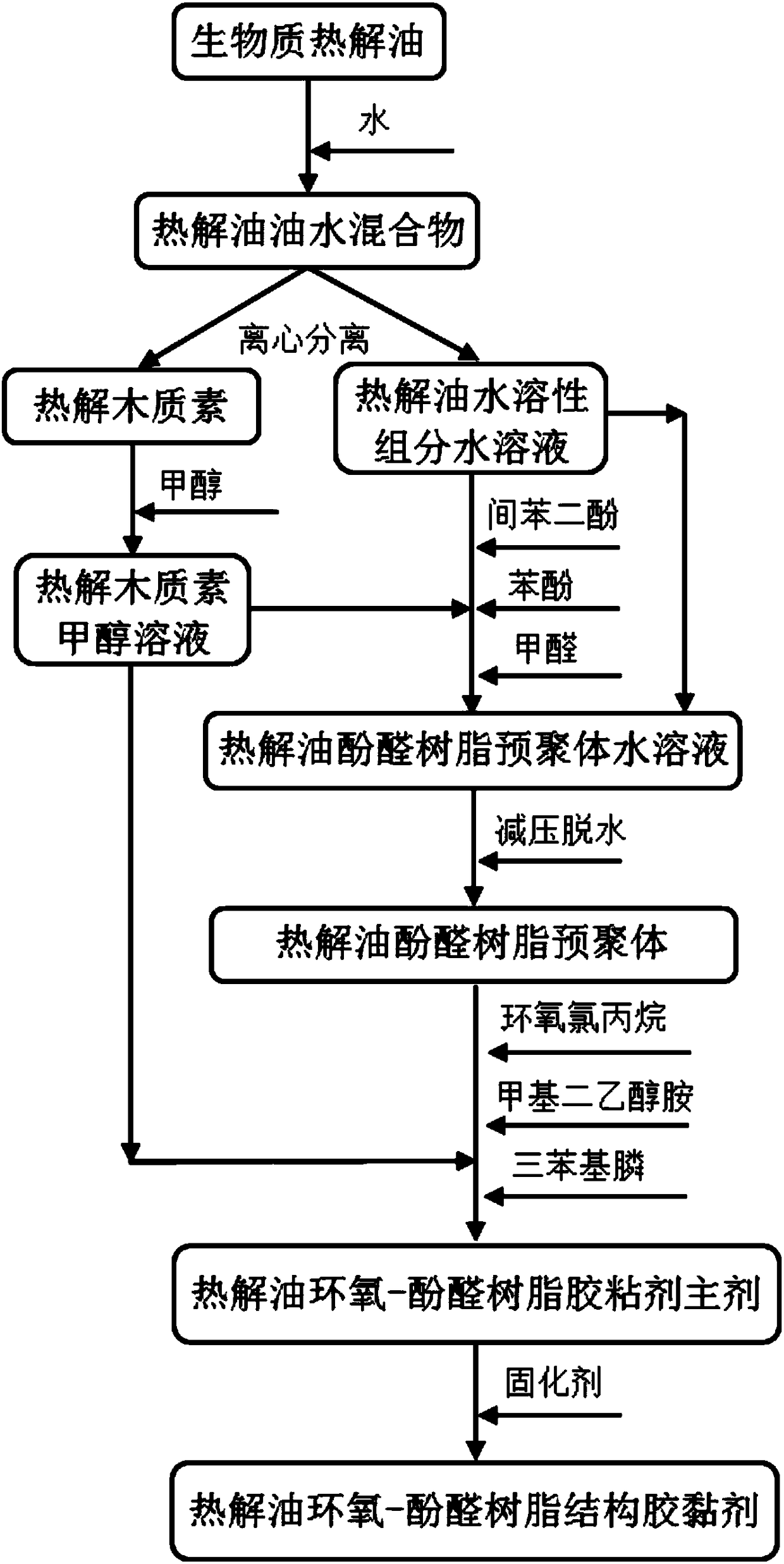

Method used

Image

Examples

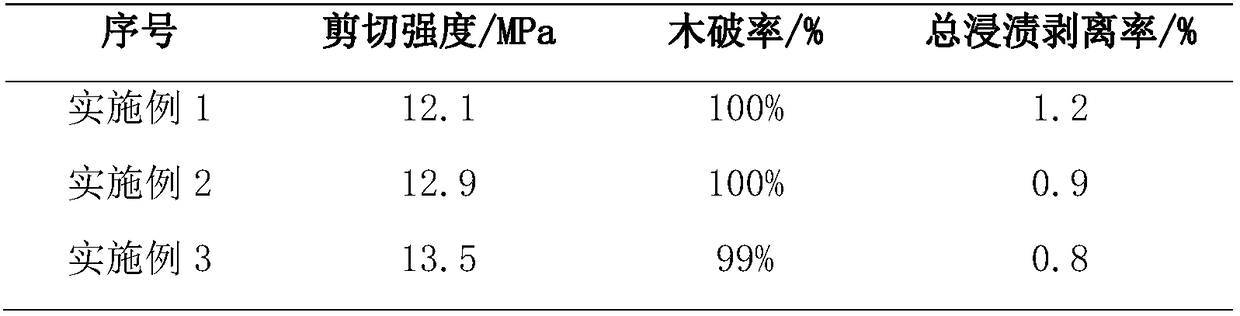

Embodiment 1

[0027] The normal temperature curing biomass pyrolysis oil-based structural adhesive was prepared by the following process:

[0028] (1) Take 40 parts of cotton stalk pyrolysis oil and add it to a centrifuge container, then add 160 parts of water, perform ultrasonic treatment for 30 minutes, and then centrifuge in a centrifuge at 3000 rpm for 25 minutes;

[0029] (2) filter the pyrolysis oil oil-water mixture after centrifugation, the filtrate is the aqueous solution (yield is about 190 parts) of water-soluble components in the pyrolysis oil, and the remaining solid insolubles are pyrolysis lignin components (yield about 10 copies);

[0030] (3) 10 parts of pyrolytic lignin components are dissolved in 20 parts of anhydrous methanol to prepare 30 parts of pyrolytic lignin methanol solution;

[0031] (4) Add 95 parts of pyrolysis oil water-soluble component aqueous solution, 35 parts of resorcinol, 35 parts of phenol, 75 parts of 37% formaldehyde solution and 15 parts of pyroly...

Embodiment 2

[0036] The normal temperature curing biomass pyrolysis oil-based structural adhesive was prepared by the following process:

[0037] (1) Take 60 parts of poplar wood pyrolysis oil and add it to the centrifuge container, then add 160 parts of water, carry out ultrasonic treatment for 30 minutes, and then centrifuge for 25 minutes in a centrifuge at 3000 rpm;

[0038](2) Filtrate the pyrolysis oil oil-water mixture after centrifugation, the filtrate is the aqueous solution (productivity is about 200 parts) of water-soluble components in the pyrolysis oil, and the remaining solid insolubles are pyrolysis lignin components (productivity about 20 copies);

[0039] (3) 20 parts of pyrolytic lignin components are dissolved in 40 parts of anhydrous methanol to prepare 60 parts of pyrolytic lignin methanol solution;

[0040] (4) Add 100 parts of pyrolysis oil water-soluble component aqueous solution, 40 parts of resorcinol, 40 parts of phenol, 80 parts of 37% formaldehyde solution and...

Embodiment 3

[0045] The normal temperature curing biomass pyrolysis oil-based structural adhesive was prepared by the following process:

[0046] (1) Get 40 parts of larch wood bark pyrolysis oil and add in the centrifuge container, then add 120 parts of water and carry out ultrasonic treatment for 30 minutes, then centrifuge in a centrifuge at 3000 rpm for 25 minutes;

[0047] (2) The pyrolysis oil oil-water mixture after centrifugation is filtered, and the filtrate is the aqueous solution (productivity is about 140 parts) of water-soluble components in pyrolysis oil, and the remaining solid insolubles are pyrolysis lignin components (productivity about 20 copies);

[0048] (3) 20 parts of pyrolytic lignin components are dissolved in 40 parts of anhydrous methanol to prepare 60 parts of pyrolytic lignin methanol solution;

[0049] (4) Add 70 parts of pyrolysis oil water-soluble component aqueous solution, 45 parts of resorcinol, 45 parts of phenol, 90 parts of 37% formaldehyde solution a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com