Light-emitting diode epitaxial growth method

A light-emitting diode and epitaxial growth technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of uneven wavelength distribution of epitaxial wafers, increased testing and sorting costs, and large wavelength dispersion of epitaxial wafers. And sorting cost, uniformity improvement, and the effect of improving warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0038] Specific embodiment one: 1 time annealing

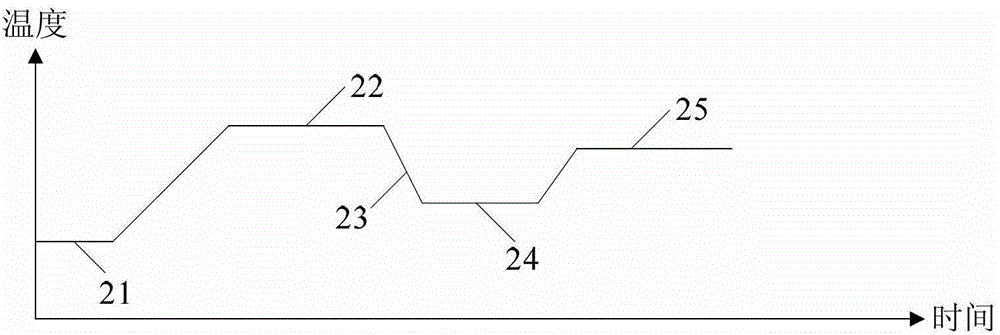

[0039] figure 2 It is a schematic diagram of the temperature structure for one-time annealing epitaxial growth. Combine below figure 2 The light-emitting diode epitaxial growth method provided in this embodiment is described in detail, and the method includes:

[0040] 1. Put the sapphire (Patterned Sapphire Substrate, PSS for short) substrate into the reaction chamber, N 2 :H 2 : NH 3 The flow rate ratio is (0:120:0) liters per minute (Standard Liter per Minute, referred to as SLM), the reaction chamber pressure is 500 Torr Torr, the temperature is raised to 1080 ° C, stabilized for 300 seconds, and the substrate is purified at high temperature .

[0041] 2. Lower the temperature to 550°C, N 2 :H 2 : NH 3 The flow rate ratio is (75:150:56) SLM, the reaction chamber pressure is controlled at 500 Torr, and a low-temperature GaN buffer layer 21 with a thickness of 35 nm is grown.

[0042] 3. Raise the temperature to ...

specific Embodiment 2

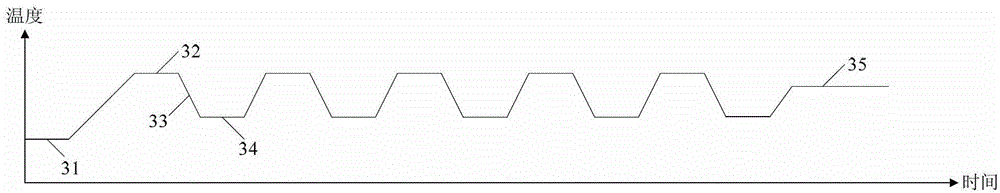

[0050] Specific embodiment two: 5 times of constant temperature annealing

[0051] image 3 It is a schematic diagram of the temperature structure for five times of isothermal annealing epitaxial growth. Combine below image 3 The light-emitting diode epitaxial growth method provided in this embodiment is described in detail, and the method includes:

[0052] 1. Put the sapphire PSS substrate into the reaction chamber, N 2 :H 2 : NH 3 The flow rate ratio is (0:120:0) SLM, the reaction chamber pressure is 500Torr, the temperature is raised to 1080°C, stabilized for 300 seconds, and the substrate is purified at high temperature.

[0053] 2. Lower the temperature to 550°C, N 2 :H 2 : NH 3 The flow rate ratio is (75:150:56) SLM, the reaction chamber pressure is controlled at 500 Torr, and a low-temperature GaN buffer layer 31 with a thickness of 35 nm is grown.

[0054] 3. Raise the temperature to 1080°C, N 2 :H 2 : NH 3 The flow rate ratio is (75:150:56) SLM, the reac...

specific Embodiment 3

[0063] Specific embodiment three: 3 times of variable temperature annealing

[0064] Figure 4 It is a schematic diagram of the temperature structure for epitaxial growth with three temperature-variable annealings. Combine below image 3 The light-emitting diode epitaxial growth method provided in this embodiment is described in detail, and the method includes:

[0065] 1. Put the sapphire PSS substrate into the reaction chamber, N 2 :H 2 : NH 3 The flow rate ratio is (0:120:0) SLM, the reaction chamber pressure is 500Torr, the temperature is raised to 1080°C, stabilized for 300 seconds, and the substrate is purified at high temperature.

[0066] 2. Lower the temperature to 540°C, N 2 :H 2 : NH 3 The flow rate ratio is (75:150:56) SLM, the reaction chamber pressure is controlled at 500 Torr, and a low-temperature GaN buffer layer 41 with a thickness of 35 nm is grown.

[0067] 3. Raise the temperature to 1020°C, N 2 :H 2 : NH 3 The flow rate ratio is (75:150:56) SL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com