Oil shale tailings beneficiation process

A technology for oil shale and final ore, which is applied in solid separation, sieve, grid, etc., can solve the problems of unusable conventional jig coal preparation technology, inability to effectively separate oil shale, and unfavorable subsequent transformation, etc. Achieve the effect of improving resource utilization, wide practicability and increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

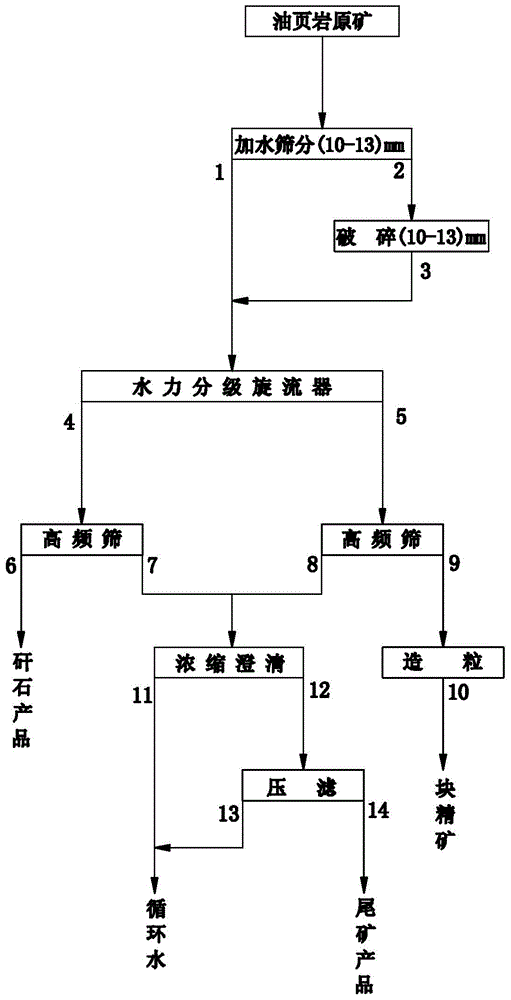

[0019] Such as figure 1 Shown, a kind of oil shale end ore beneficiation process step of the present invention is as follows:

[0020] a. Carrying out (10-13)mm sieving of the oil shale raw ore, producing the under-sieve product 1 with a particle size of -(10-13)mm and the over-sieve product 2 with a particle size of +(10-13)mm;

[0021] b. The product 2 on the sieve is crushed to less than (10-13) mm to become the crushed material 3 with a crusher, and mixed with the product 1 under the sieve;

[0022] c. The mixed material is classified by a hydroclassifying cyclone, and two kinds of materials are produced after classification, the underflow product 4 and the overflow product 5;

[0023] d. Underflow product 4 is dehydrated by high-frequency sieve to produce gangue product 6 and coal slime water 7;

[0024] e. The overflow product 5 is dehydrated by a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com