Intelligent sorting system and working method thereof

A sorting system and working method technology, applied in sorting, stacking of objects, conveyors, etc., can solve the problems of slow overall progress of the packaging process, inability to achieve synchronization, and large floor space, so as to make full use of storage space , Improve space utilization, eliminate the effect of blind spot of light source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

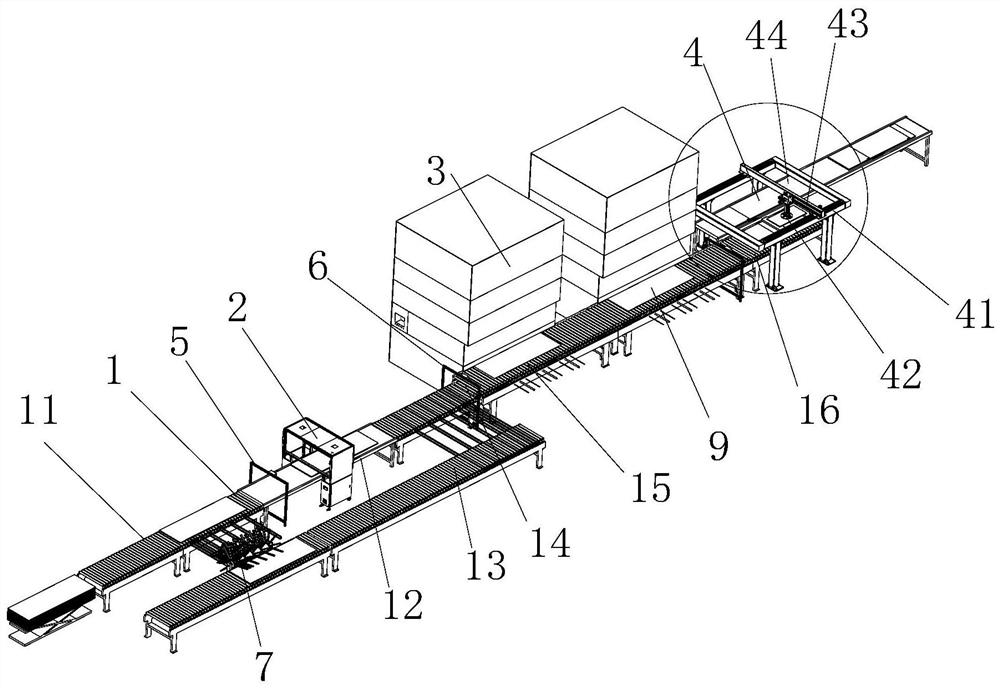

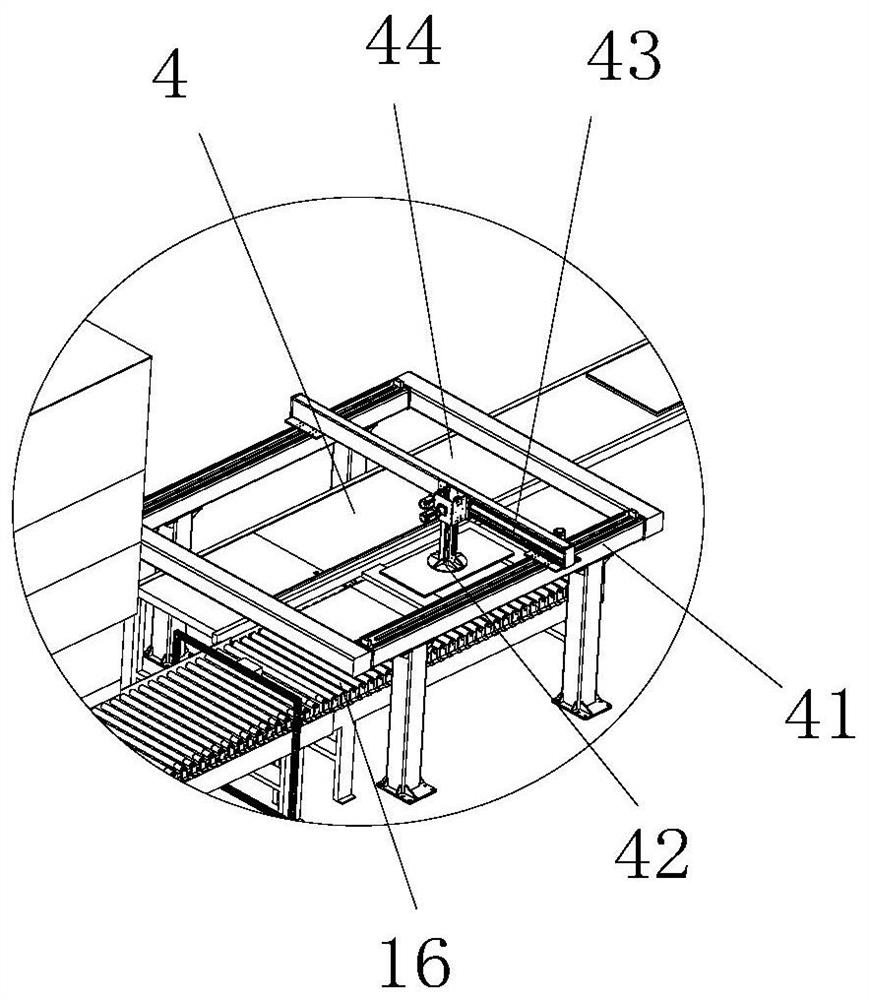

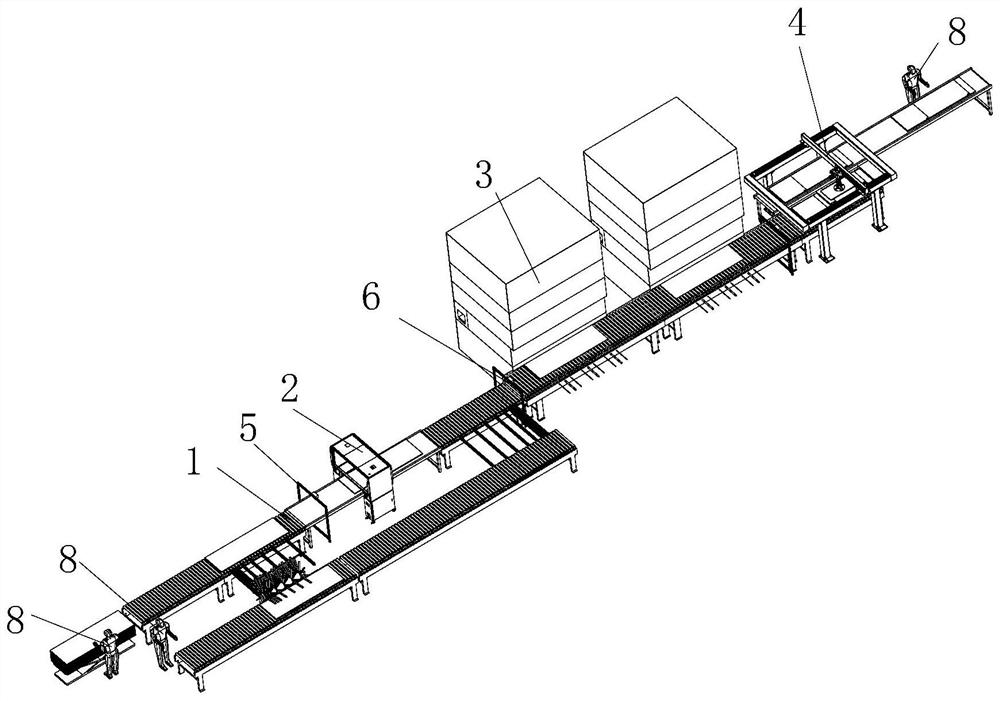

[0060] See Figure 1 to Figure 3 , an intelligent sorting system, including a conveying mechanism 1, a detection mechanism 2, a storage and sorting mechanism 3, a palletizing mechanism 4 and a control mechanism (not shown in the figure), the detection mechanism 2 and the storage and sorting mechanism 3 The input end is respectively provided with a first code scanning mechanism 5 and a second code scanning mechanism 6 .

[0061] The conveying mechanism 1 is used to convey the plate 9, which includes a conveying bracket and a feeding area, a detection area, a storage and sorting area and a stacking area successively arranged on the feeding bracket;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com