Electrolytic aluminum anode waste separating and recovering method

An electrolytic aluminum anode, separation and recovery technology, applied in the direction of solid separation, magnetic separation, chemical instruments and methods, etc., can solve the problems of failure to recycle and reuse waste materials, achieve low cost, realize industrial automation flow production, and reduce labor demand small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

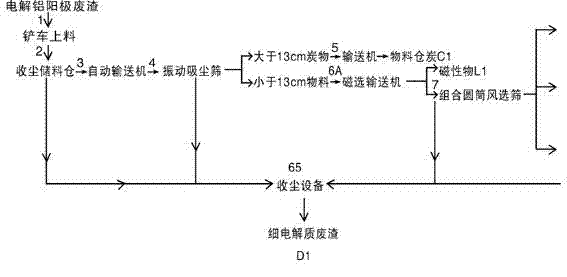

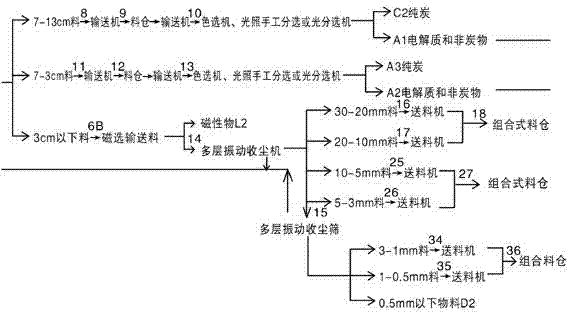

[0031] Such as Figure 1~5 shown, where figure 1 It is a general picture, because the width of the picture is too large, it is divided into four parts, and each of the four parts is a picture ( Figure 2 to Figure 5 ), the four figures are combined into a complete schematic diagram of the route of the present invention. Electrolytic aluminum waste, feeding (forklift 1), dust collection storage bin 2, automatic conveyor 3, vibrating dust collector sieve 4, separated into carbon materials larger than 13 cm and materials smaller than or equal to 13 cm, of which: The charcoal material larger than 13 cm is sent to the material bin carbon C1 through the conveyor 5; the material bin C1 is collected for use; the material smaller than or equal to 13 cm is separated into magnetic material L1 by the magnetic separation conveyor 6A, and the rest is combined by the cylinder Wind screen 7, decomposed into 7-13 cm material (greater than 7 cm, less than or equal to 13 cm, excluding 7 cm) a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com