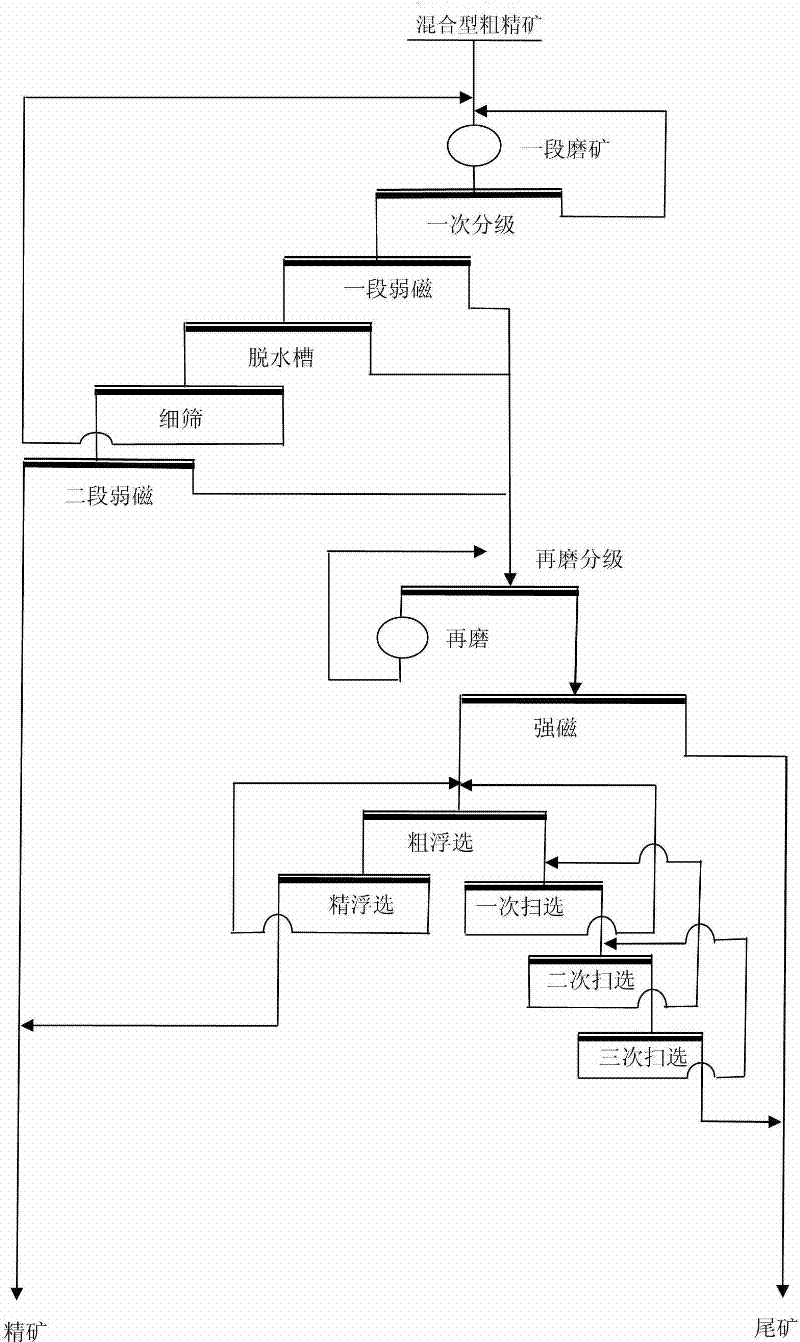

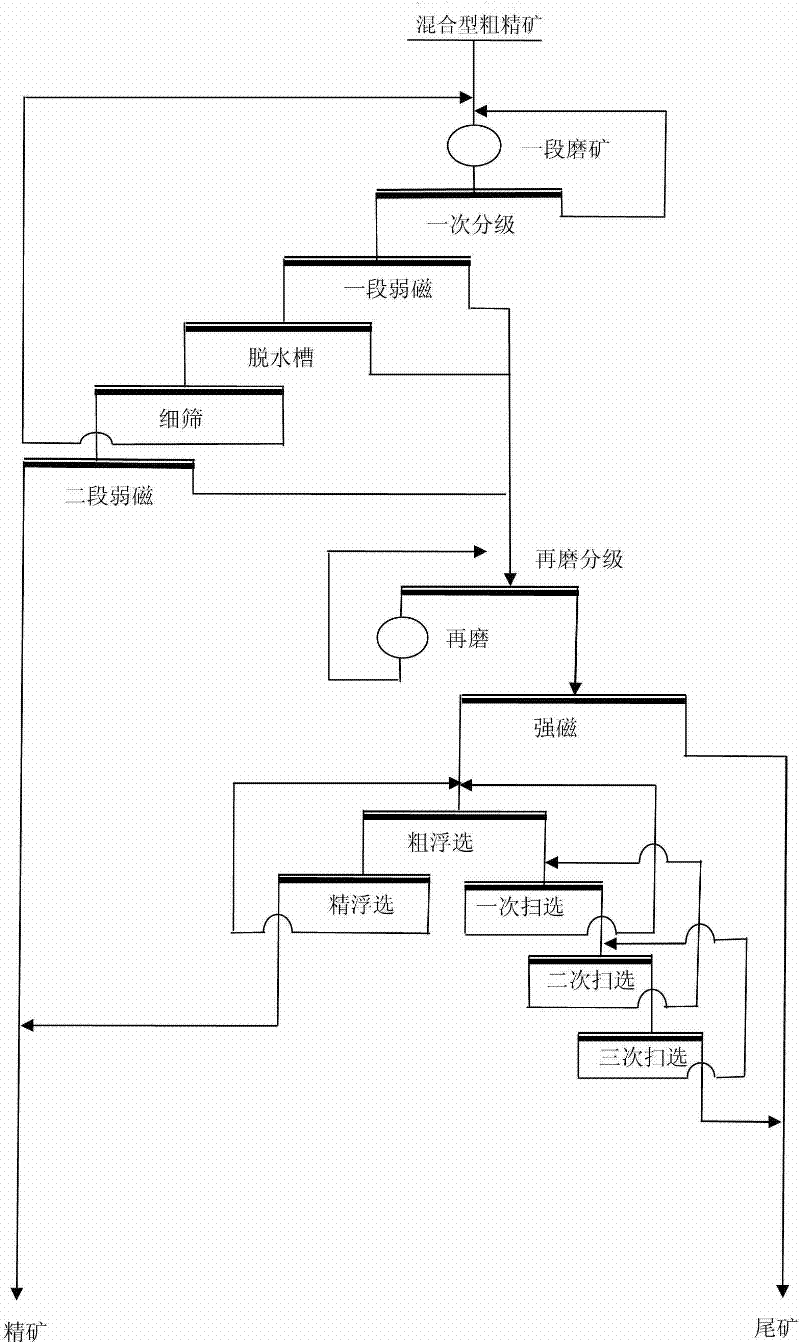

Mineral separation process for magnetic hematite rough concentrates

A mixed-type, coarse concentrate technology, applied in flotation, magnetic separation, solid separation, etc., can solve the problems of high tailings grade, low metal recovery rate, low recovery rate of fine-grained hematite, etc. High concentrate grade and metal recovery rate, efficient utilization of resources, and easy to achieve the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] 1) Feed the magnetic and erythroic mixed coarse concentrate with a particle size of -200 mesh, content of 65.2%, grade of 51.2%, and silica content of 20.6% into a closed-circuit grinding system consisting of one-stage grinding and one-stage classification.

[0088] 2) Grain size -200 mesh, content 94.24%, weight concentration 35.0% of a graded overflow is fed into a section of weak magnetic separator, the magnetic field strength of a section of weak magnetic separator is 2150 Oe, the concentrate grade of a section of weak magnetic is 59.87%, and a section of weak magnetic Magnetic tailings grade is 49.35%,

[0089] 3) A section of weak magnetic concentrate is fed into the dehydration tank. The magnetic field strength of the dehydration tank is 950 Oe. Mesh sieve with a mesh size of 0.09×0.09mm,

[0090] 4) The coarse-grained products on the sieve are returned to the first stage of grinding, and the fine-grained products under the sieve are sent to the second-stage wea...

Embodiment 2

[0101] 1) Feed the magnetic and red mixed type coarse concentrate with a particle size of -200 mesh, a content of 67.51%, a grade of 54.49%, and a silica content of 16.10% into a closed-circuit grinding system consisting of one-stage grinding and one-stage classification.

[0102] 2) Grain size -200 mesh, content 93.74%, weight concentration 33.5% of a graded overflow is fed into a section of weak magnetic separator, the magnetic field strength of a section of weak magnetic separator is 2100 Oe, the concentrate grade of a section of weak magnetic is 60.60%, and a section of weak magnetic Magnetic tailings grade is 49.57%,

[0103]3) A section of weak magnetic concentrate is fed into the dehydration tank. The magnetic field strength of the dehydration tank is 900 Oe. Mesh sieve with a mesh size of 0.09×0.09mm,

[0104] 4) The coarse-grained products on the sieve are returned to the first-stage grinding, and the fine-grained products under the sieve are sent to the second-stage...

Embodiment 3

[0115] 1) Feed the mixed magnetic and erythroic coarse concentrate with a particle size of -200 mesh, content of 72.0%, grade of 57.30%, and silica content of 12.24% into a closed-circuit grinding system consisting of one-stage grinding and one-stage classification,

[0116] 2) Grain size -200 mesh, content 93.50%, weight concentration 35.5% primary graded overflow is fed into a section of weak magnetic field, the magnetic field strength of a section of weak magnetic separator is 2000 Oe, the concentrate grade of a section of weak magnetic field is 60.88%, and a section of weak magnetic Magnetic tailings grade is 49.64%,

[0117] 3) A section of weak magnetic concentrate is fed into the dehydration tank. The magnetic field strength of the dehydration tank is 850 Oe. Mesh sieve with a mesh size of 0.08×0.08mm,

[0118] 4) The coarse-grained products on the sieve are returned to the first stage of grinding, and the fine-grained products under the sieve are sent to the second-st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com