Automatic sorting garbage bin

An automatic sorting and trash can technology, which is applied in the field of trash cans, can solve the problems of high equipment cost, many impurities, and large volume, and achieve the effects of reducing labor intensity, shortening the sorting process, and saving recycling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

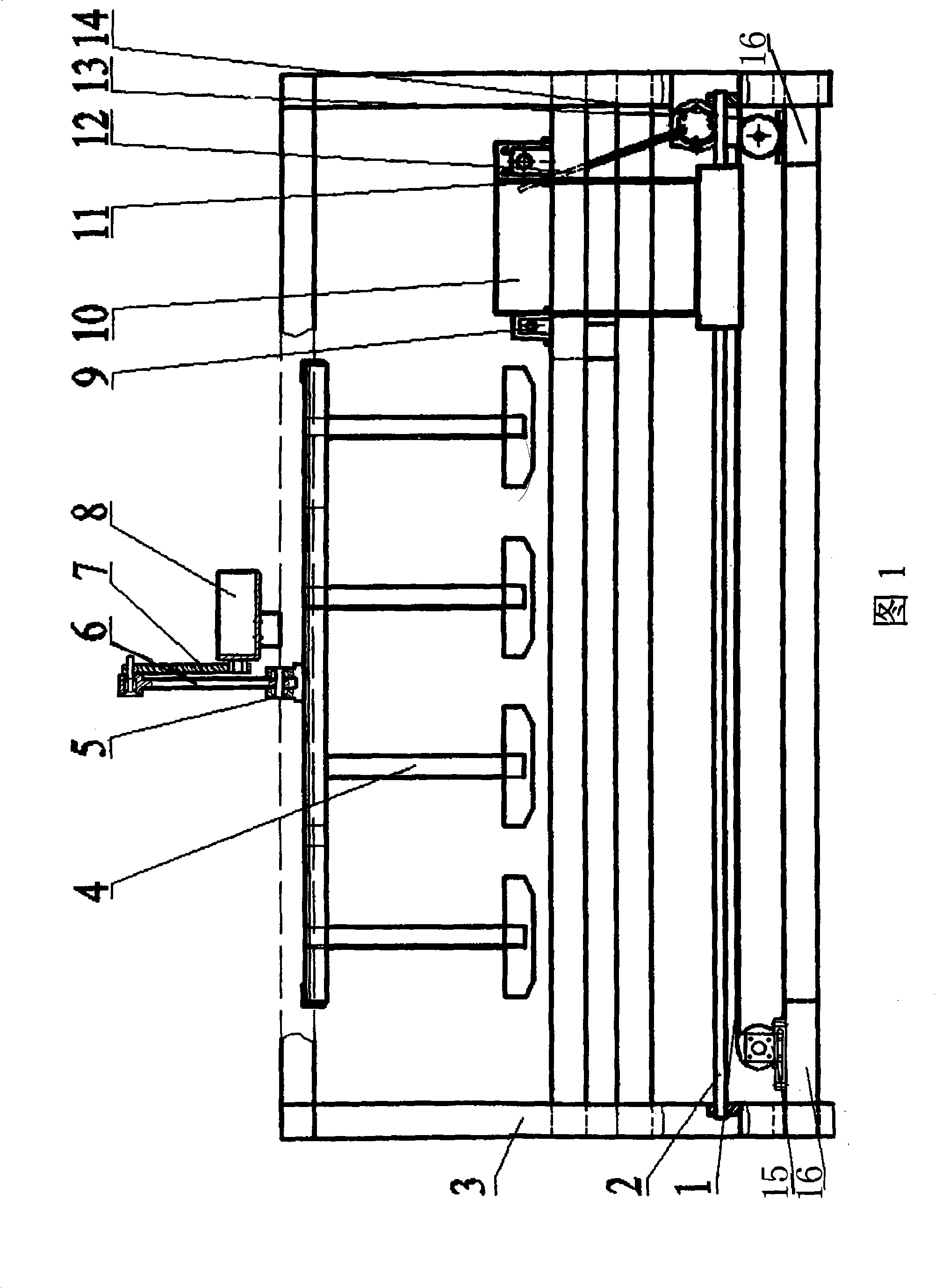

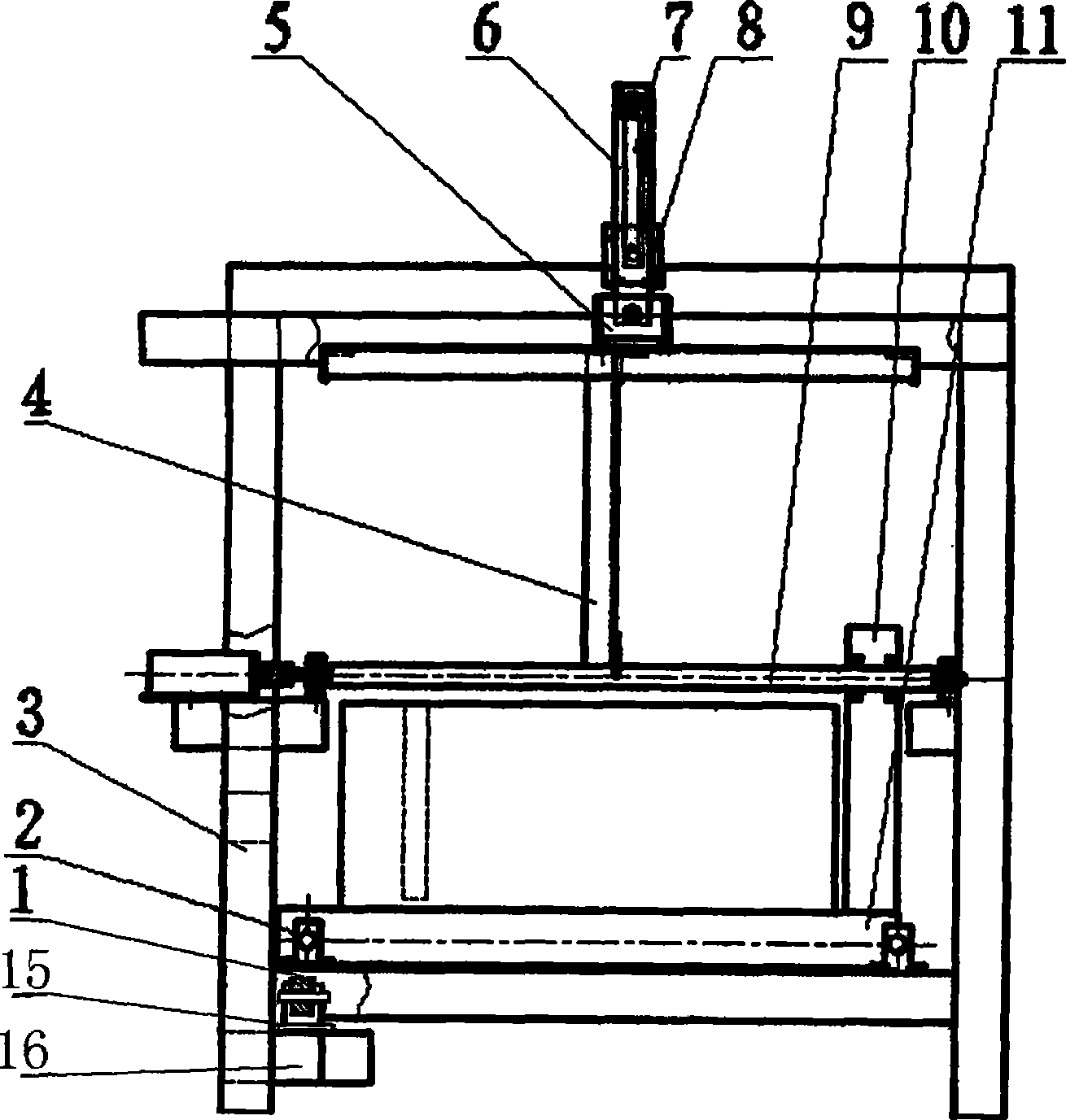

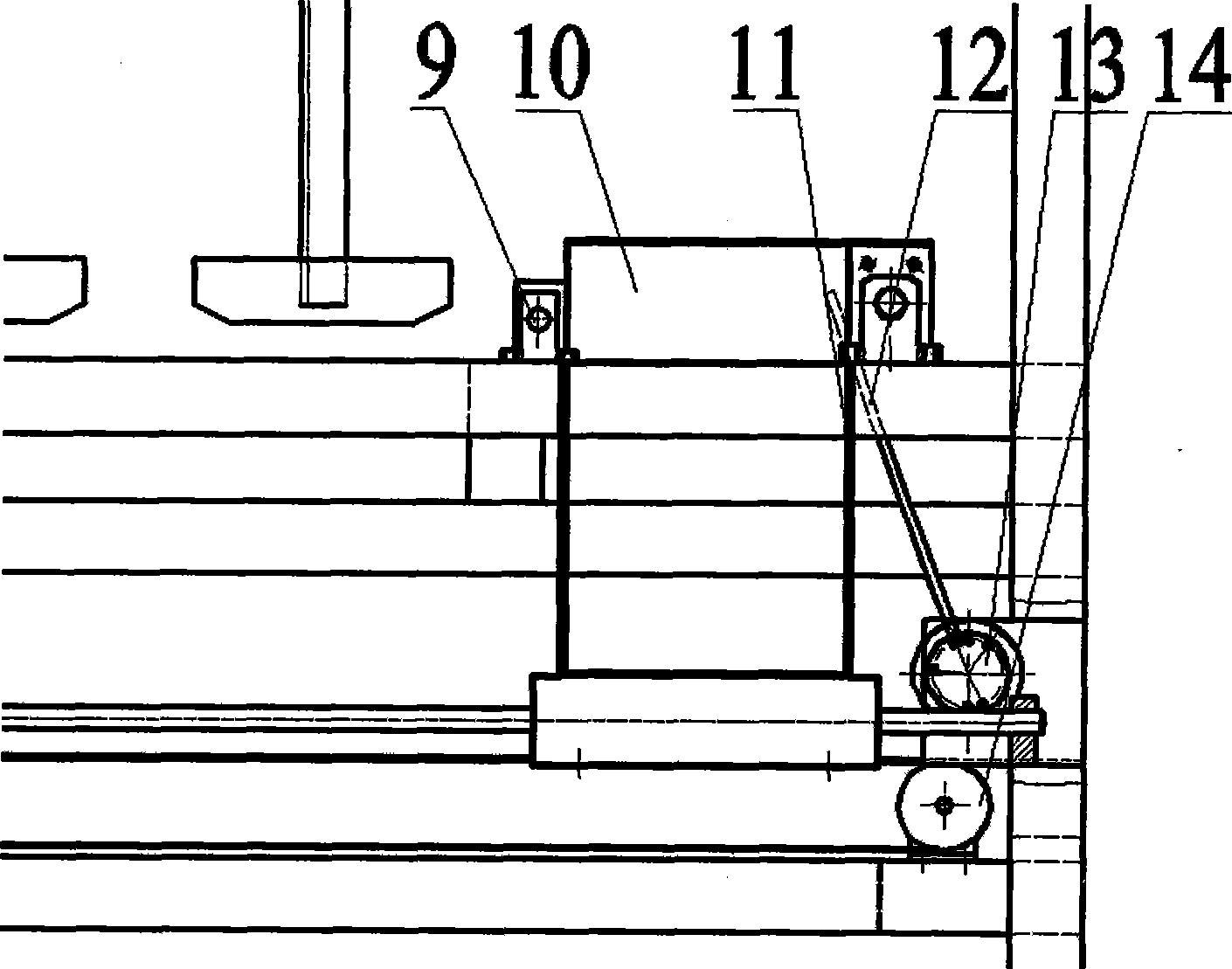

[0025] The principle, structure and working process of the present invention will be further described below with reference to the accompanying drawings.

[0026] The overall principle of material classification and identification is: first, metal detectors are used to detect metals. Secondly, the external force forces the object under test to vibrate locally, and the detection of glass bottles and plastic bottles is realized by collecting and analyzing the fundamental frequency of the sound signal. The fundamental frequency characteristics of the material are: the fundamental frequency of the sound emitted by striking glass is greater than 1.5kHz; the fundamental frequency of the sound emitted by striking plastic is less than 1kHz. In addition, objects that are easily compressed or that are too small are considered other garbage.

[0027] In order to realize the predetermined function and combine the principle of sound analysis, the actuator of the mechanical part of garbage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com