High-transparency ultraviolet-blocking energy-saving film and solution-fusion preparation method thereof

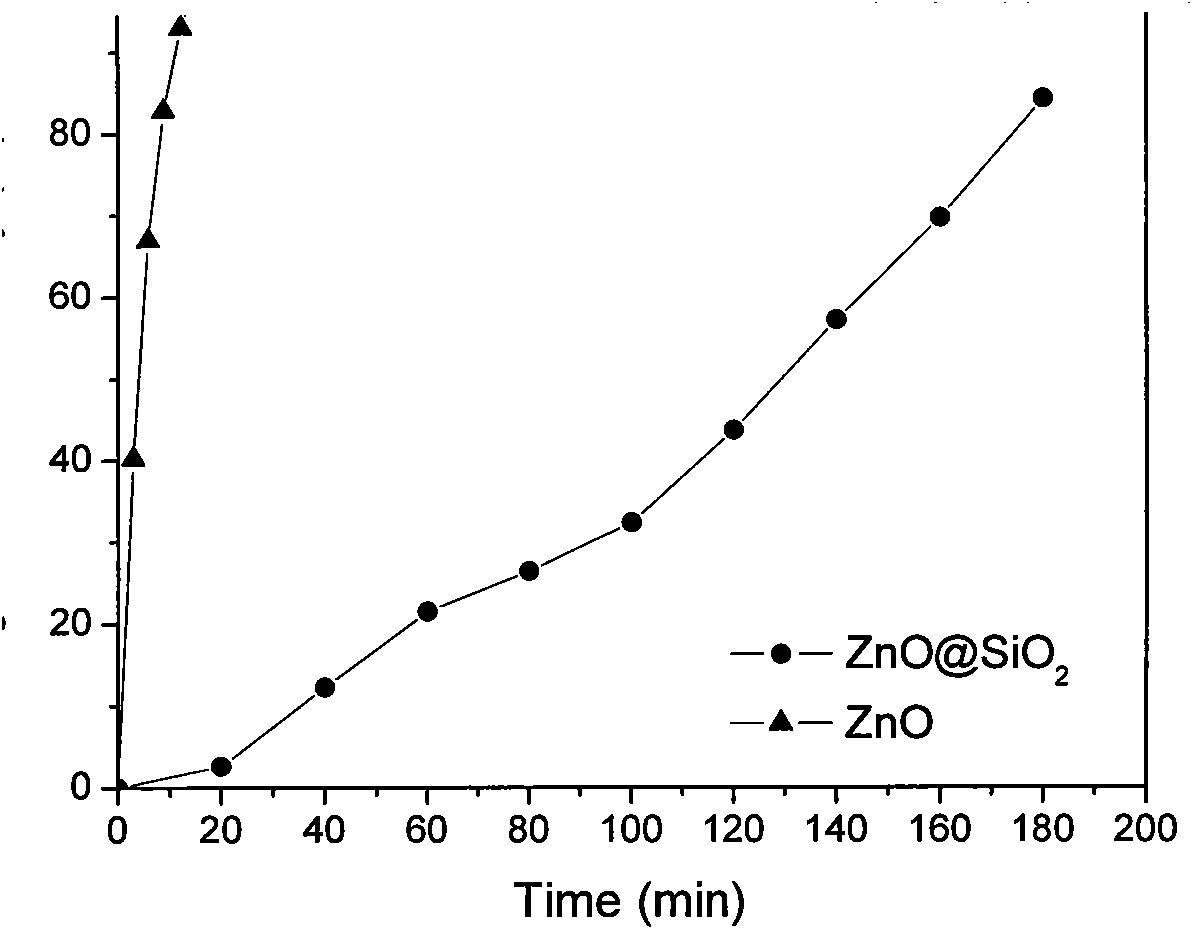

A transparent violet, energy-saving film technology, which is applied in the field of polymer-inorganic nanoparticle composite technology to synthesize composite films, can solve the problems of coating yellowing, reduce the service life of the coating, etc., achieve low production costs, increase energy-saving performance, UV Excellent shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1) The methanol solution (initial dispersion) of the core-shell structure ZnO nanoparticles is centrifuged and washed, then transferred to absolute ethanol, and ultrasonically dispersed to make a concentration of 5.88wt% core-shell structure ZnO nanoparticles The ethanol dispersion liquid, the ZnO nanoparticles in the dispersion liquid are in the shape of long rods with a diameter of about 50nm;

[0047] 2) Take by weighing 220g of the core-shell structure ZnO nanoparticle ethanol dispersion liquid prepared in step 1), add 633.86g absolute ethanol, just add 12.963g PVB powder while stirring, make PVB dissolve, make core-shell structure nano ZnO / Dispersion of PVB in ethanol;

[0048] 3) The ethanol dispersion of the core-shell structure nano ZnO / PVB obtained in step 2) is spray-dried on a spray dryer to obtain a dry powder masterbatch of ZnO:PVB=1:1;

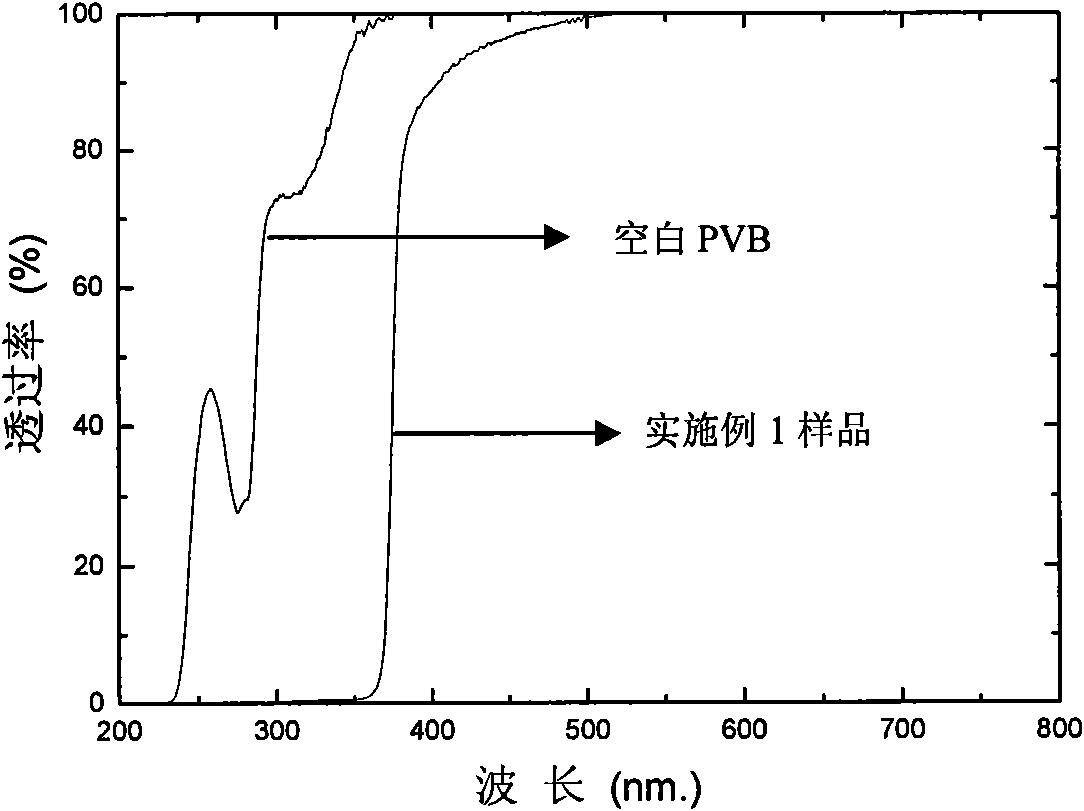

[0049] 4) Weigh the dry powder masterbatch prepared in step 3) with PVB and plasticizer DOS in a ratio of 2:99:20 by w...

Embodiment 2

[0056] 1) The dry powder masterbatch prepared in step 3 of Example 1 and PVB and plasticizer DBS are weighed in a ratio of 2:99:40 by weight (the actual proportioning of ZnO, PVB, DBS is 1: 100:40), fully mixed uniformly in a high-speed mixer to obtain a complete recipe, the composition (weight percentage) is shown in Table 2-1:

[0057] composition

[0058] table 2-1

[0059] 2) Injection molding the complete recipe prepared in step 1) in an injection molding machine, the temperature of the feeding section is 100-120°C, the temperature of the melting section is 120-150°C, and the outlet temperature is 130-140°C. The sample prepared by injection molding was pressed between two pieces of quartz glass to form a thin film. The thickness of the obtained thin film was 0.22mm. The optical performance test results are shown in Table 2-2.

[0060] Visible light transmittance (%) (550nm)

[0061] Table 2-2

Embodiment 3

[0063] 1) according to the method of embodiment 1 step 1), make the ethanol dispersion liquid of the core-shell structure ZnO nanoparticle that concentration is 5.88wt%;

[0064] 2) Take by weighing 220g step 1) the core-shell structure ZnO nanoparticle ethanol dispersion liquid prepared, add 356.56g dehydrated alcohol, just add 5.544g PVB powder while stirring, make PVB dissolve, make core-shell structure nano ZnO / Dispersion of PVB in ethanol;

[0065] 3) The ethanol dispersion of the core-shell structure nano ZnO / PVB obtained in step 2) is spray-dried on a spray dryer to obtain a dry powder masterbatch of ZnO:PVB=7:3;

[0066] 4) Weigh the dry powder masterbatch prepared in step 3) with PVB and plasticizer 3G8 according to the actual ratio of ZnO, PVB and 3G8 at 2:100:35, and fully mix them evenly in a high-speed mixer to obtain a complete formula material, its composition (weight percentage) is shown in Table 3-1;

[0067] composition

[0068] Table 3-1

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com