Recycling method and recycling device for cathode material and anode material of spent lithium-ion battery

A technology of lithium ion battery and recycling method, which is applied in the field of recycling and recycling device of positive and negative electrode materials of waste lithium ion battery, can solve the problems of reducing recycling efficiency, increasing process flow, increasing recycling cost, etc., so as to reduce recycling cost and separate Good effect, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

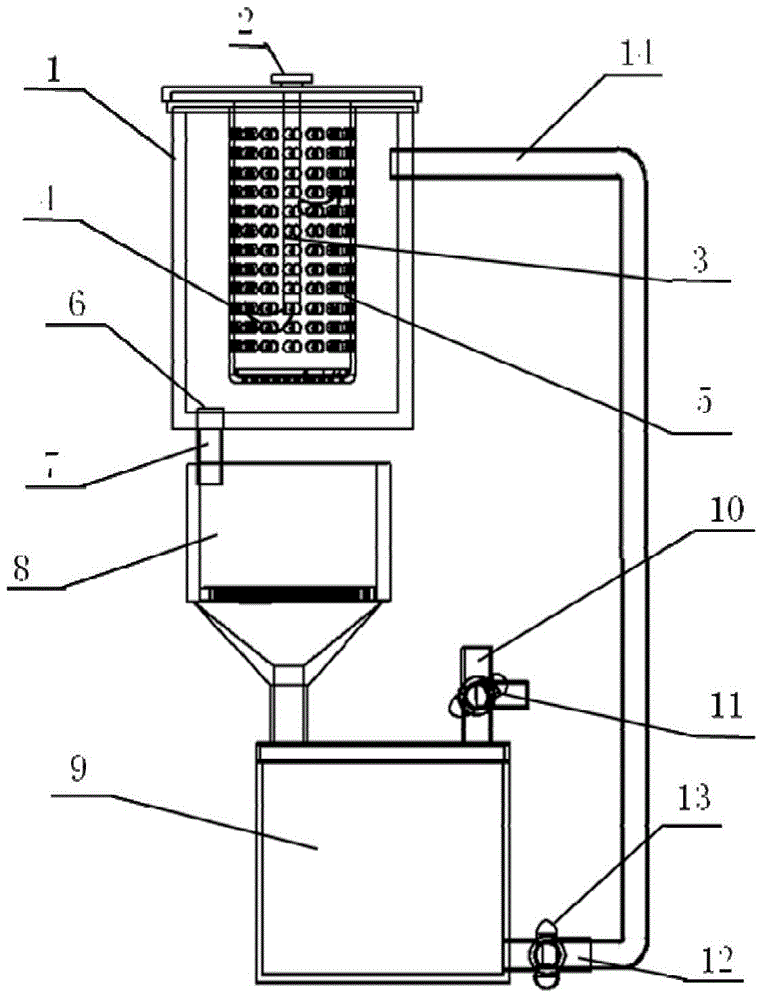

Image

Examples

Embodiment Construction

[0020] The following is a recycling method for positive and negative materials of waste lithium-ion batteries:

[0021] Discharge the waste lithium-ion battery first, remove the shell, and then break the inner core of the battery into 2-4 cm pieces, immerse in a solvent mixed with water and ethanol at a volume ratio of 2:1, and stir for 2-10 min with the aid of mechanical stirring. The positive and negative electrode materials are separated from the diaphragm, foil, etc., and then filtered to recover the positive and negative electrode materials, and the solvent can be recycled again. The polar solvent system is a mixed solvent system of water and ethanol mixed in a certain volume ratio, and the waste lithium ion battery can be lithium iron phosphate battery, lithium manganate battery, ternary lithium ion battery, etc.

[0022] The above recovery method is carried out according to the following separation mechanism:

[0023] According to the principle of similar miscibility, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com