PVC (polyvinyl chloride) power pipeline material and preparation method thereof

A technology for power pipes and raw materials, applied in pipes, rigid pipes, mechanical equipment, etc., can solve the problems of unsatisfactory flame retardant effect, difficult to achieve, increase product cost, etc., and achieve low production cost, simple process, and flame retardant performance. Good results

Active Publication Date: 2013-01-16

安徽安诺热能科技有限公司

View PDF2 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

If the flame retardant formula is unreasonable, the flame retardant effect is not ideal. If the flame retardant performance is improved by increasing the amount of addition, it will increase the cost of the product and affect the bending performance of the material, making it difficult to meet the national standards.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

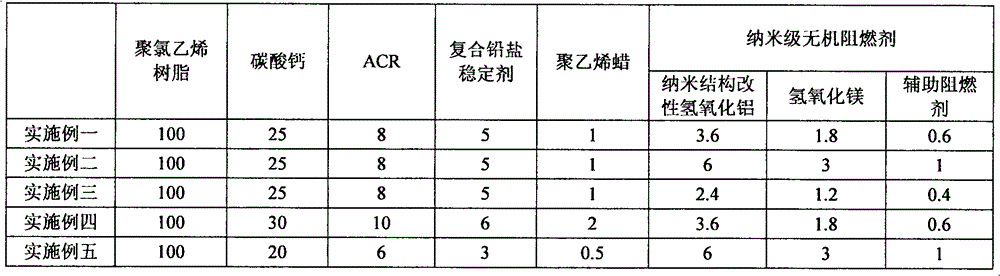

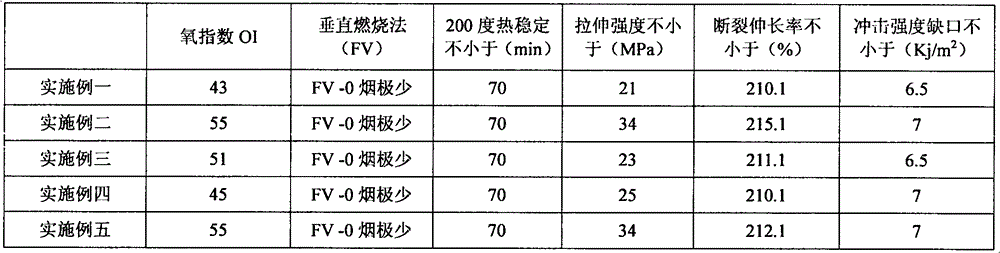

[0012] Provide the component of the embodiment of the present invention PVC power pipe material and the list of parts by weight below:

[0013] Table 1 Component and Content Table

[0014]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

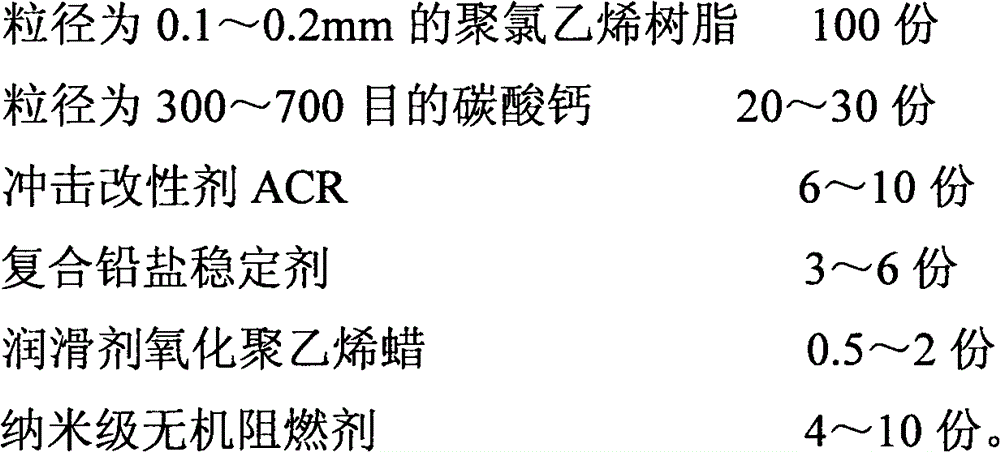

The invention discloses PVC (polyvinyl chloride) power pipeline material. The PVC power pipeline material comprises, by weight, 100 parts of polyvinyl chloride resin 0.1-0.2mm in particle size, 20-30 parts of calcium carbonate 300-mesh to 700-mesh in particle size, 6-10 parts of impact modifier ACR, 3-6 parts of composite lead salt stabilizer, 0.5-2 parts of lubricant oxidized polyethylene wax, and 4-10 parts of nano-scale inorganic flame retardant. The PVC power pipeline material is high in flame retardancy with oxygen index up to more than 40. PVC power pipelines of the power pipeline material is high in rigidity, heat resistance and ageing resistance, low in manufacturing cost and simple in processing technique.

Description

technical field [0001] The invention belongs to the technical field of polyvinyl chloride composite materials, in particular relates to a PVC power pipe material, and also relates to a preparation method of the power pipe. Background technique [0002] The threading pipe is a hard rubber pipe for electrical installation and wiring, including PVC and PE threading pipes. The threading pipe needs to meet the requirements of anti-corrosion, anti-leakage and flame retardancy. The formula of PVC plastic pipe is mainly composed of PVC resin and additives, among which additives are divided into heat stabilizers, lubricants, processing modifiers, impact modifiers, fillers, anti-aging agents, colorants, etc. . [0003] The threading pipes that are often used in construction have higher requirements for flame retardancy because they are used to install wires. At present, the standard for flame-retardant line pipe is mainly the national quality standard GB8624-2006. Threading pipes c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L27/06C08K13/06C08K9/00C08K3/26C08K3/22C08K3/38C08K3/32F16L9/12

Inventor 张婷婷

Owner 安徽安诺热能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com