Method for improving machining thermal stability of chlorinated polyvinyl chloride resin

A chlorinated polyvinyl chloride, resin processing technology, applied in the field of chlorinated polyvinyl chloride resin processing, can solve the problem of affecting the Vicat softening point and heat distortion temperature of the blend, loss of CPVC heat resistance, large amount of stabilizer, etc. Problems, to achieve good static and dynamic thermal stability, to meet the effect of thermal stability needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

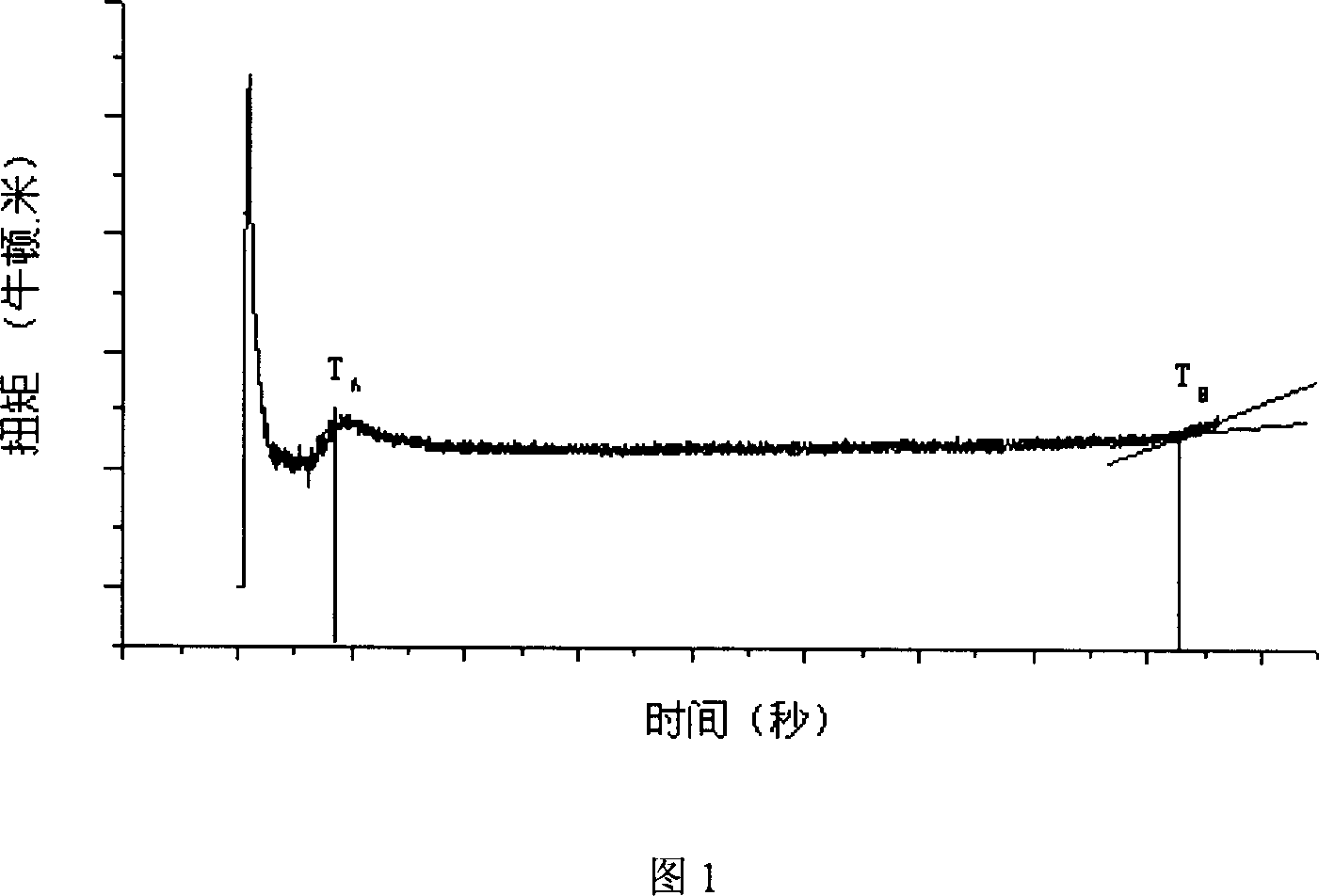

Image

Examples

Embodiment 1

[0029] 100 parts of CPVC resin, 2 parts of hydrotalcite and 3.5 parts of lubricant (0.5 part of glyceric fatty acid ester, 0.5 part of paraffin wax, 1.0 part of polyethylene wax and 1.0 part of oxidized polyethylene wax) and 8 parts of impact modifier (methyl methacrylate-styrene-butadiene copolymer), mix in a high-speed mixer, heat up to 125°C, then cool to below 50°C and discharge, test static and dynamic thermal stability, test data see table 1.

Embodiment 2

[0031] 100 parts of CPVC resin, 4 parts of hydrotalcite and 3.5 parts of lubricant (0.5 part of glyceric fatty acid ester, 0.5 part of paraffin wax, 1.0 part of polyethylene wax and 1.0 part of oxidized polyethylene wax) and 8 parts of impact modifier (methyl methacrylate-styrene-butadiene copolymer), mix in a high-speed mixer, heat up to 120-130°C, then cool to below 50°C and discharge, test static and dynamic thermal stability, test data See Table 1.

Embodiment 3

[0033] 100 parts of CPVC resin, 6 parts of hydrotalcite and 3.5 parts of lubricant (0.5 part of glyceric fatty acid ester, 0.5 part of paraffin wax, 1.0 part of polyethylene wax and 1.0 part of oxidized polyethylene wax) and 8 parts of impact modifier (methyl methacrylate-styrene-butadiene copolymer), mix in a high-speed mixer, heat up to 120-130°C, then cool to below 50°C and discharge, test static and dynamic thermal stability, test data See Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com