Hydraulic-motor angular speed servo system

A technology of hydraulic motor and servo system, which is applied in the direction of electric speed/acceleration control, etc., to achieve the effect of improving stability, insensitive to system performance changes, and avoiding overshoot phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention is described in further detail:

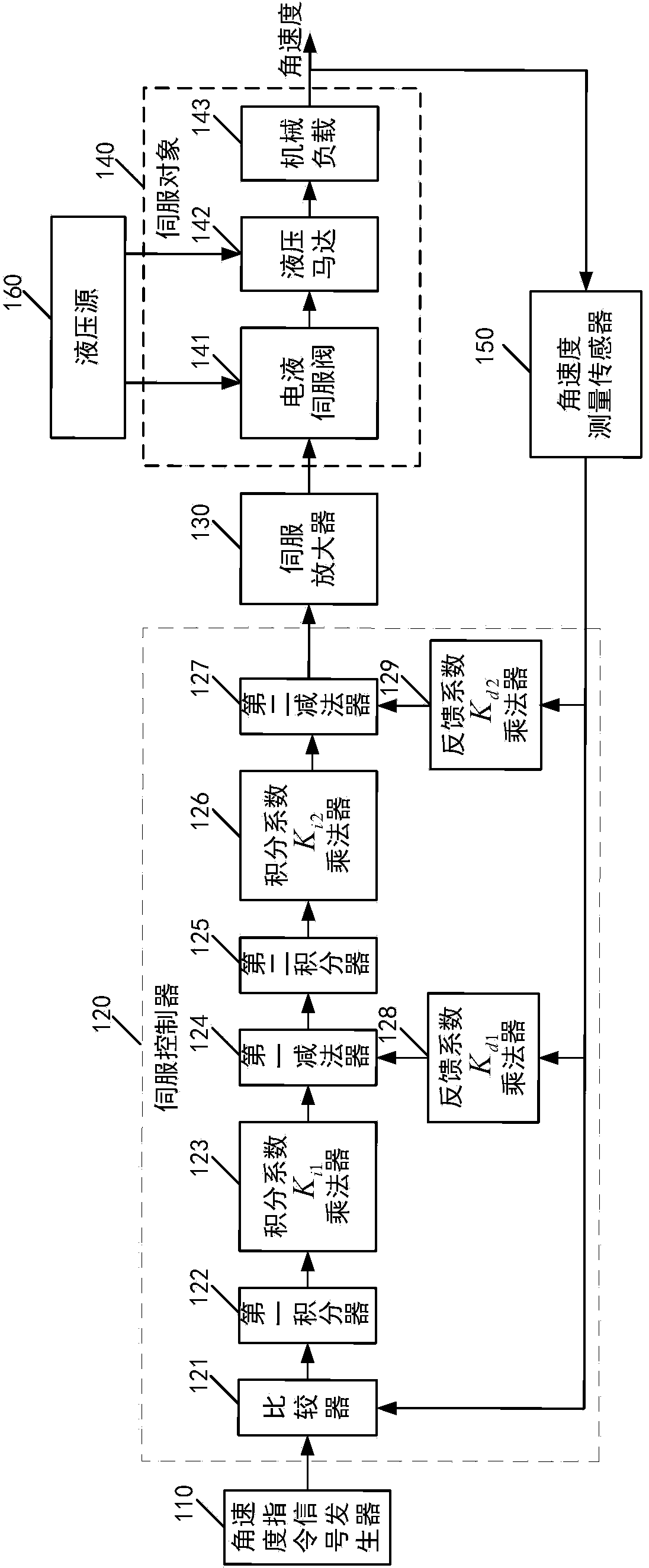

[0021] Such as figure 1 Shown is a block diagram of the electro-hydraulic angular velocity servo system of the present invention. This electro-hydraulic angular velocity servo system is made up of angular velocity command signal generator 110, servo controller 120, servo amplifier 130, servo object 140, angular velocity measuring sensor 150 and hydraulic pressure source 160; Integrator 122, integral coefficient K i1 Multiplier 123, first subtractor 124, second integrator 125, integral coefficient K i2 Multiplier 126, second subtractor 127, feedback coefficient K d1 Multiplier 128 and the feedback coefficient K d2 The multiplier 129 is composed of the comparator 121, the first integrator 122, the integral coefficient K i1 Multiplier 123, first subtractor 124, second integrator 125, integral coefficient K i2 The multiplier 126 and the second subtractor 127 are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com