Method of making photosensitive lead salt thin film of infrared detector

An infrared detector, photosensitive lead salt technology, used in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., to achieve the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

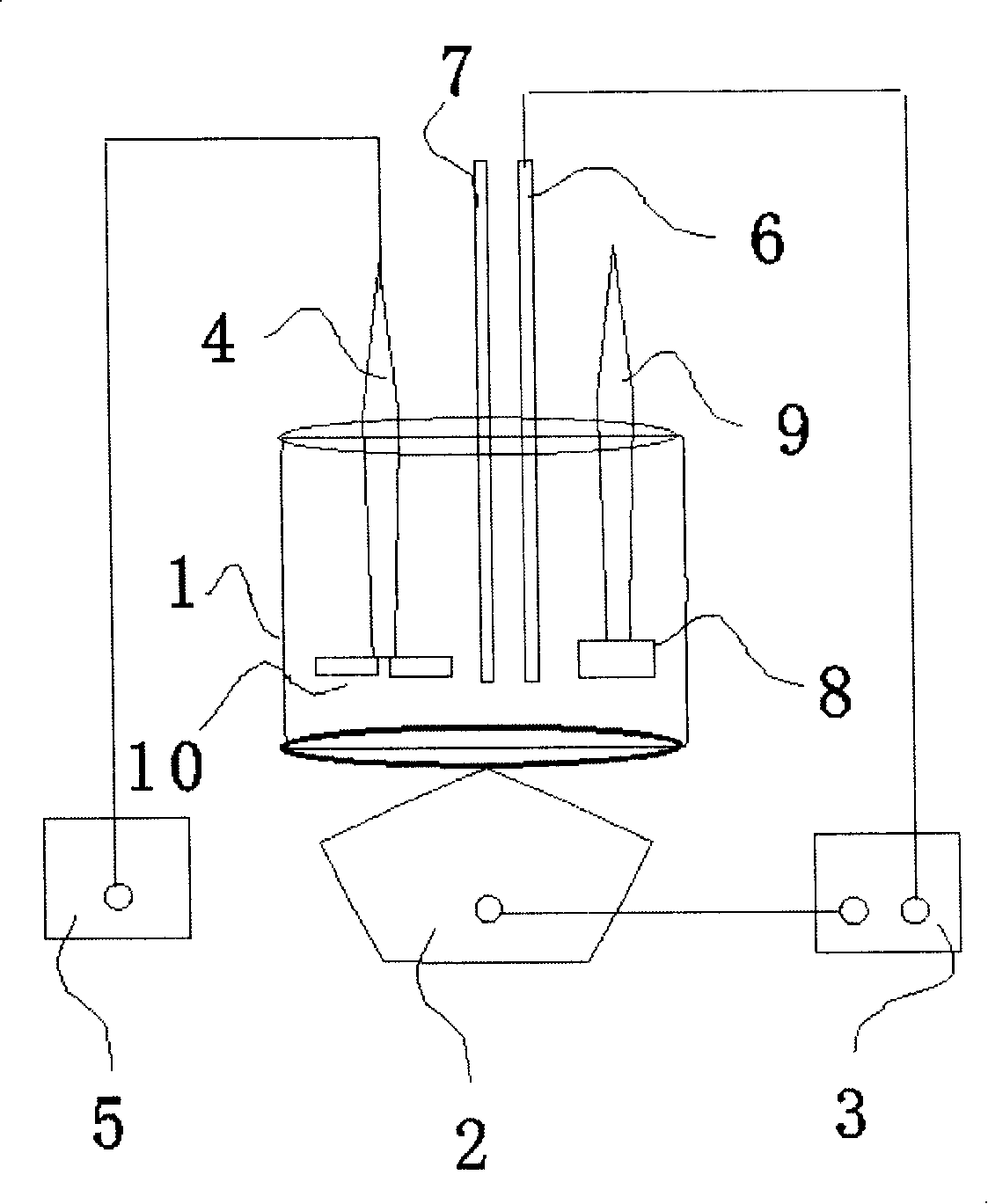

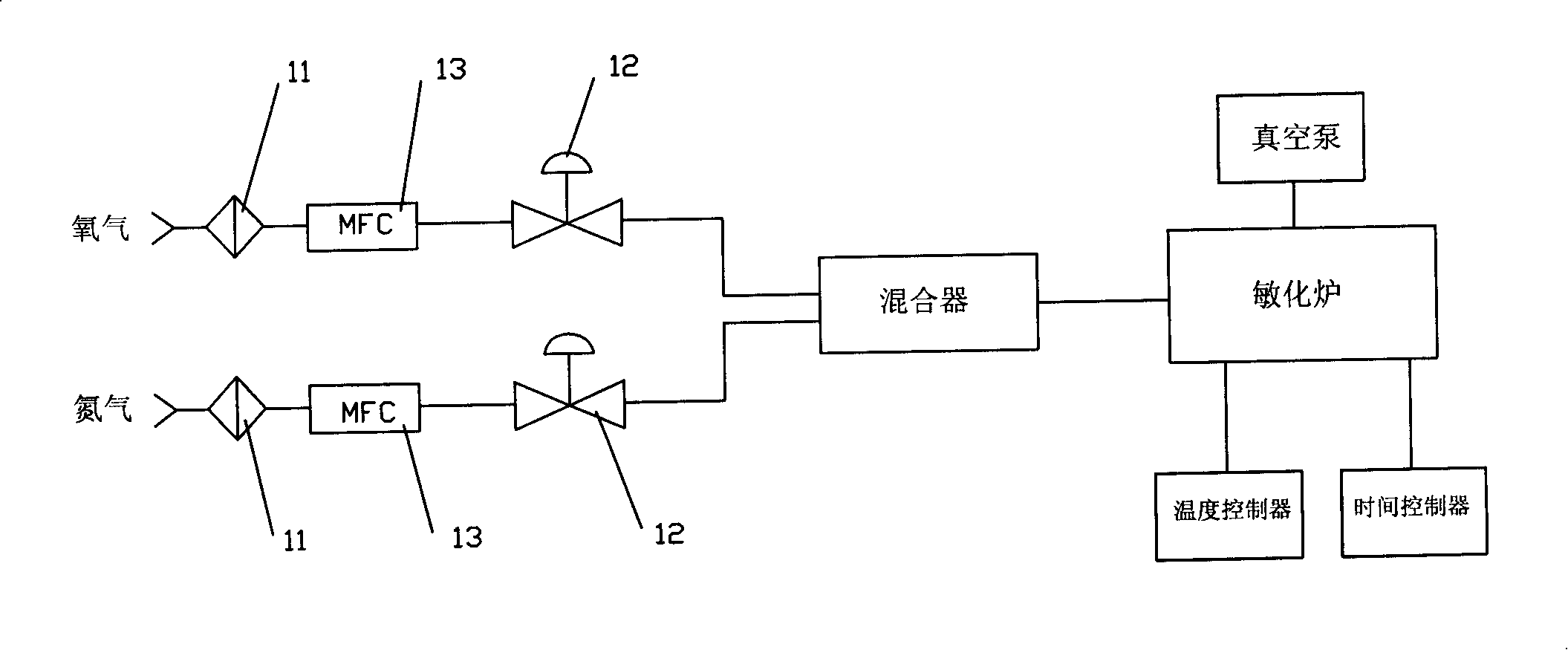

[0040]figure 1 Shown is the precipitation device used in the preparation of infrared detector photosensitive lead salt thin film according to the present invention. The substrate 8 is placed on the sample holder 9, and it is placed in a reaction kettle filled with the reaction mother liquor during precipitation. The substrate is completely immersed in the reaction mother solution. The temperature controller 3 receives the temperature of the reaction mother liquid fed back by the thermometer 6, and controls the heater 2 to heat the reaction mother liquid according to the required heating rate and keep the temperature according to the required time. During the reaction process, the pH value of the reaction mother liquid is monitored by a pH meter 7 and adjusted and supplemented by manually or automatically adding corresponding mother liquid components as required; after the precipitation starts, the stirring controller 5 controls the agitator 4 to drive the stirrer 10 to make th...

Embodiment 1

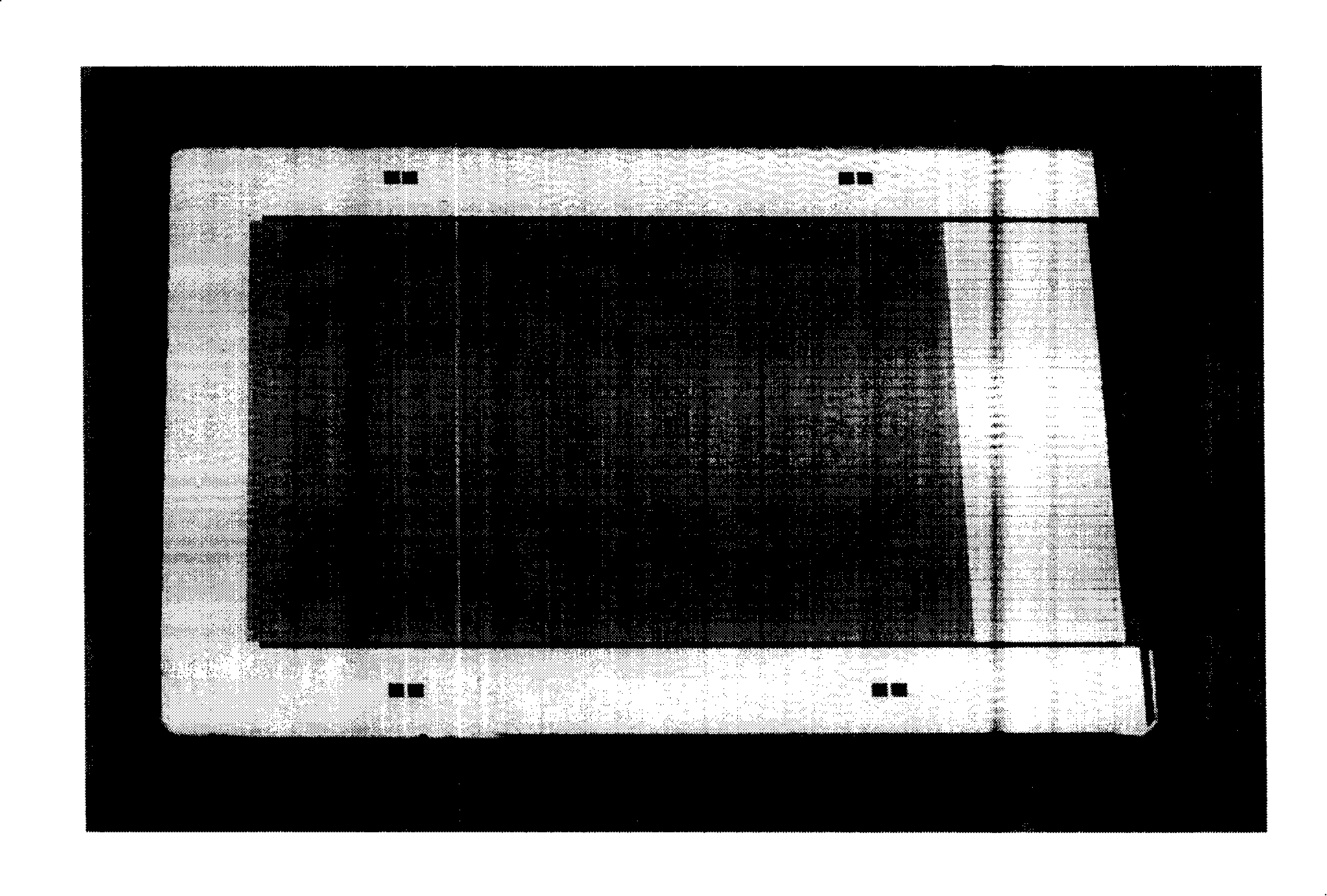

[0046] A 36mmx25mm quartz substrate is used with a thickness of 3mm. PbS films were deposited by the hydrazine method. Heating adopts an electric heating plate furnace, and stirring adopts a magnetic stirrer. The stirring rate was 500 rpm. And the PbS multi-element (42 elements) short-wave infrared detector was prepared by using the film deposited in this example.

[0047] Prepare 200ml of 0.35M lead acetate solution, 110ml of 0.35M thiourea solution, 200ml of 15% hydrazine solution and 16ml of 12% glacial acetic acid. Heat the lead acetate solution to boiling, add 15ml of glacial acetic acid, and then gradually drop the hydrazine solution into the mixture. Fix the quartz substrate on the sample holder and put it into the prepared mixed solution. After 10 minutes of pre-seed crystal process, the temperature of the mixed solution is raised to 90 degrees and kept at a constant temperature for 90 minutes. In the middle of the constant temperature process, add the same concent...

Embodiment 2

[0055] A φ5mm K9 glass substrate with a thickness of 1mm is used. PbS thin films were deposited by high temperature method. The heating is heated by infrared lamps, and the steady-speed motor drives the stirring paddle to stir. The stirring rate was 100 rpm. A unitary PbS short-wave infrared detector was prepared by precipitation in this example, and the area of the photosensitive element is 1.5 mm x 1.5 mm.

[0056] Prepare 150ml of lead acetate solution with concentration of 0.5M, 150ml of thiourea solution with concentration of 0.5M, and 100ml of NaOH solution with concentration of 50%. Mix thiourea with lead acetate solution, and add strong base (NaOH) dropwise. Fix the K9 glass substrate on the sample holder and put it into the prepared mixed solution. After 10 minutes of pre-seed crystallization process, the temperature of the mixed solution was kept constant at 22° C. for precipitation, and the precipitation time was 120 minutes. After the precipitation process i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com