Chlorinated polyvinyl chloride double-wall corrugated pipe formulation and its production process

A chlorinated polyvinyl chloride, double-wall corrugated pipe technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of poor fluidity, poor pre-plasticity, poor processing performance, etc. High, low manufacturing cost, good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

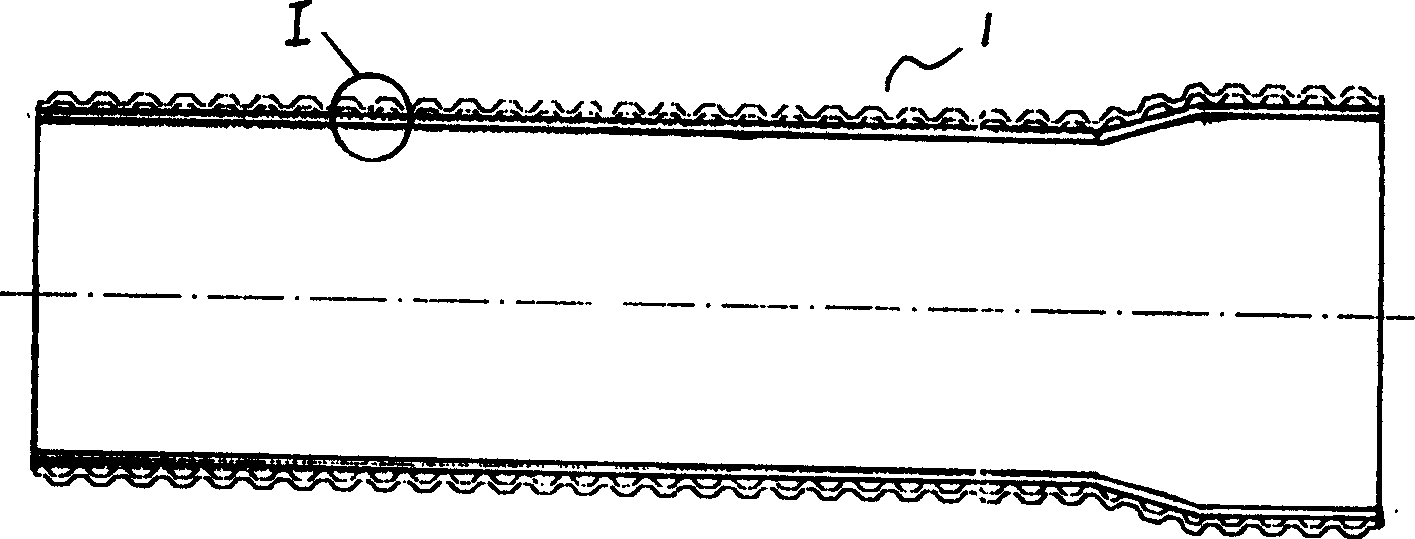

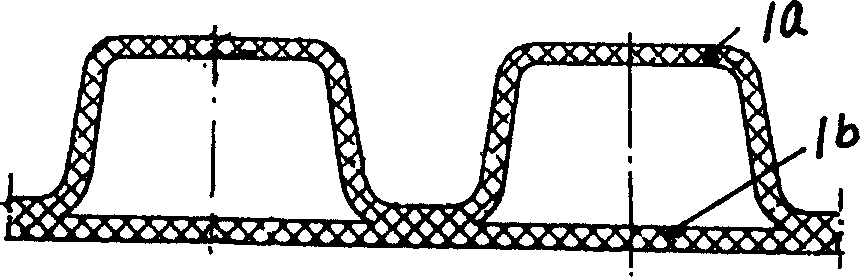

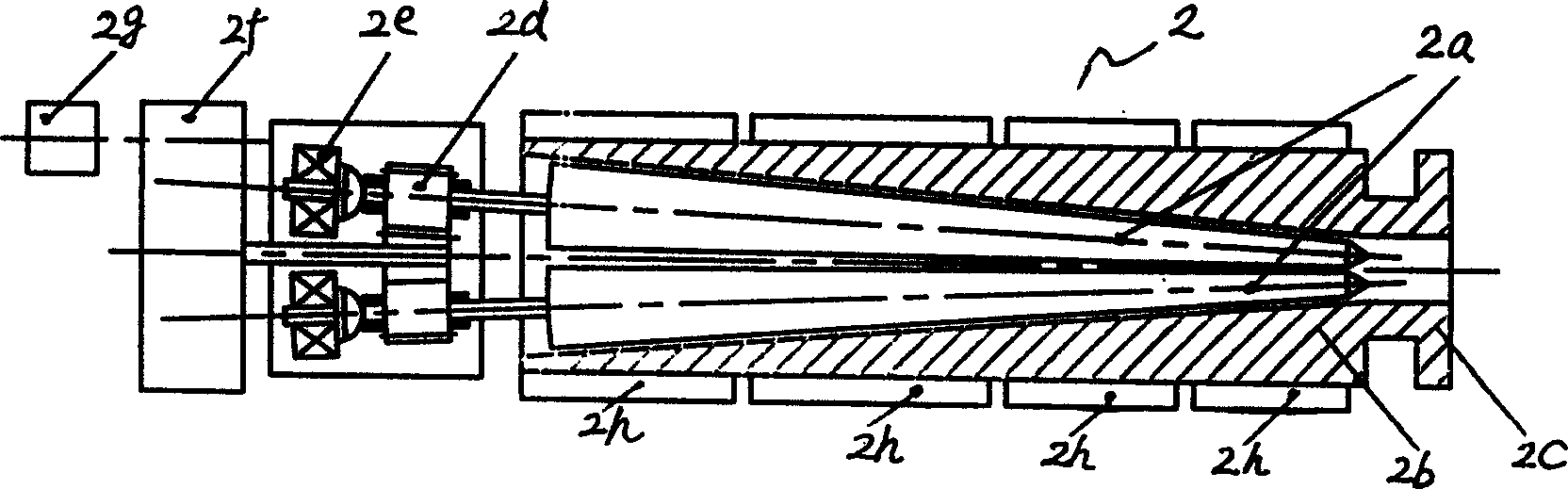

[0027] Embodiment The structure of the chlorinated polyvinyl chloride double-wall corrugated pipe of this embodiment can be obtained from figure 1 with figure 2 It can be seen in the figure that it contains the outer wall 1a and the inner wall 1b, and the air that enters the space during the molding process is left between the inner and outer walls.

[0028] The formula of the chlorinated polyvinyl chloride double-wall bellows of the present embodiment (each component is represented by weight parts) is as follows: chlorinated polyvinyl chloride resin (being CPVC resin) 50-80; Polyvinyl chloride resin (being PVC resin) 20-50; composite lead salt stabilizer 4.5-7.5; stearic acid 0.6-0.8; polyethylene wax 0.3; paraffin wax 0.3; superfine calcium carbonate 4-10; impact resistance ACR 6-8.

[0029] The molecular structure of CPVC resin in the above formula is similar to that of PVC resin, and they have good compatibility. They can be mixed in any ratio to improve the processing f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com