Method for extracting stachyose

An extraction method, stachyose technology, applied in oligosaccharides, pharmaceutical formulations, plant raw materials, etc., can solve the problems of lead salts, shorten the process time, etc., achieve the effect of high raw material utilization rate and shorten the process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

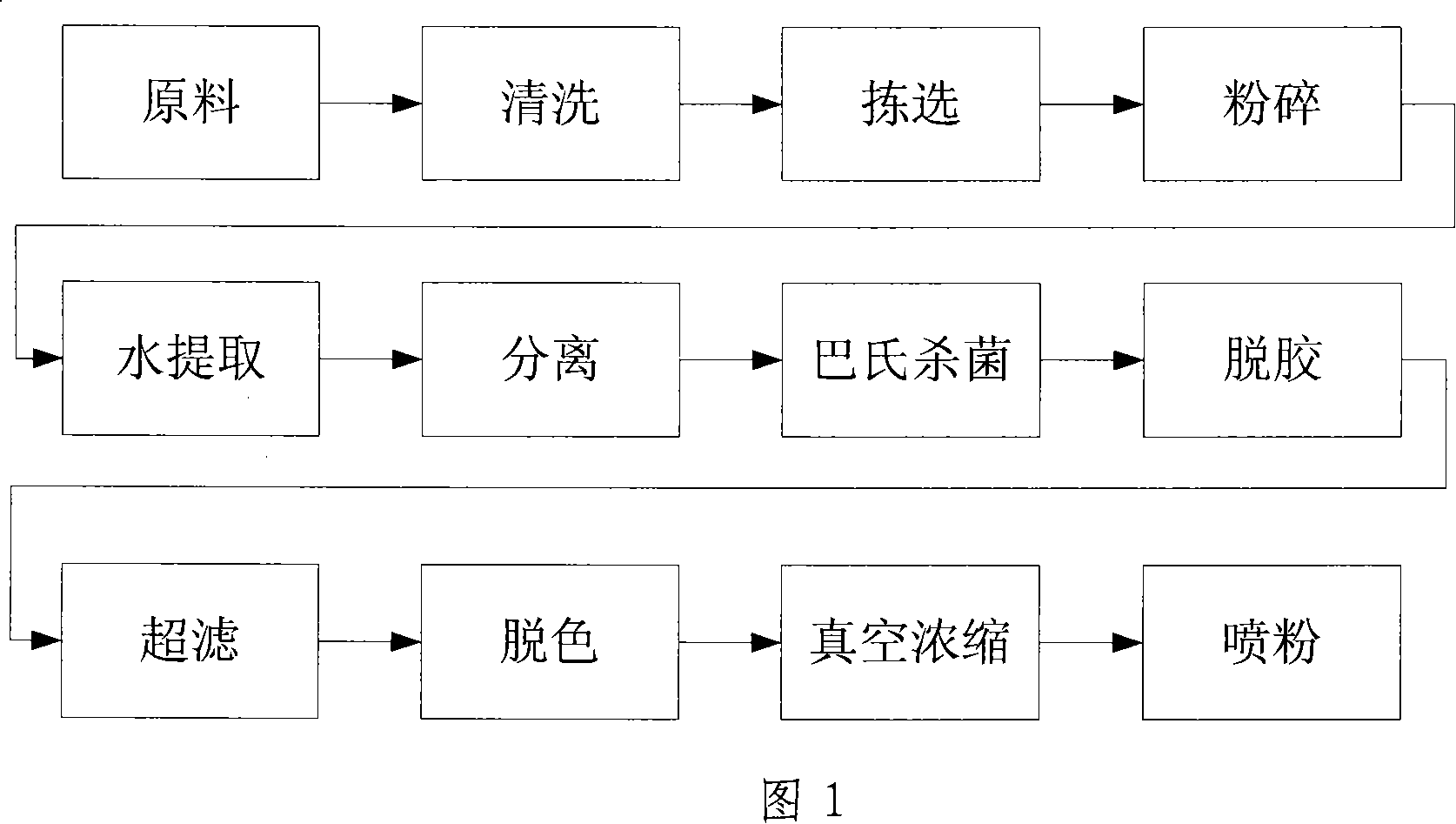

[0018] The raw materials used in the present invention can be extracted by fresh raw materials in the harvest season, and dry products can be used in the non-harvest season. Figure 1 shows the flow chart from obtaining raw materials to making finished products.

[0019] Using dried bamboo shoots as raw materials to extract stachyose:

[0020] (1) Cleaning, sorting and crushing 100kg of dried bamboo shoots as raw material, with a particle size of <5mm;

[0021] (2) leaching with 500kg of pure water at 70-80°C for 2 hours, centrifuging, separating and removing impurities from the obtained slurry to obtain an extract;

[0022] (3) Pasteurize the extract and solidify the vegetable protein at a temperature of 92±2°C for 30 seconds;

[0023] (4) adding a pectin compound enzyme preparation of 1 / 10,000 of the weight of the extract to the extract sterilized by the above step (3) and keeping it warm for 1 hour for degumming, and the temperature is controlled at 50-60° C.;

[0024] (5...

example 2

[0030] Using dried silver bars as raw material to extract stachyose:

[0031] (1) 1000kg raw material silver bar dry product is cleaned, pulverized, particle size<5mm;

[0032] (2) leaching with 5 tons of pure water at 70-80°C for 2 hours, centrifuging, separating, and removing impurities to obtain an extract;

[0033] (3) Pasteurize the extract and solidify the vegetable protein at a temperature of 92±2°C for 30 seconds;

[0034] (4) adding a pectin compound enzyme preparation of 1 / 10,000 of the weight of the extract to the extract sterilized by the above step (3) and keeping it warm for 1 hour for degumming, and the temperature is controlled at 50-60° C.;

[0035] (5) carry out ultrafiltration through the ultrafiltration membrane of 10000D through the solution after degumming through above-mentioned step (4), to remove impurities, obtain ultrafiltrate;

[0036] (6) The ultrafiltrate is decolorized in a 3-meter-high decolorizing column through the MG type decolorizing resin...

example 3

[0041] Using dried bamboo shoots as raw materials to extract stachyose:

[0042] (1) 1000kg raw material dry bamboo shoots are cleaned and pulverized, particle size<5mm;

[0043] (2) leaching with 5T pure water at 70-80°C for 2 hours, centrifuging, separating and removing impurities from the obtained slurry to obtain an extract;

[0044] (3) Pasteurize the extract and solidify the vegetable protein at a temperature of 92±2°C for 30 seconds;

[0045] (4) adding a pectin compound enzyme preparation of 1 / 10,000 of the weight of the extract to the extract sterilized by the above step (3) and keeping it warm for 1 hour for degumming, and the temperature is controlled at 50-60° C.;

[0046] (5) carry out ultrafiltration through the ultrafiltration membrane of 10000D through the solution after degumming through above-mentioned step (4), to remove impurities, obtain ultrafiltrate;

[0047] (6) The ultrafiltrate is decolorized in a 3-meter-high decolorizing column through the MG type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com