Synthesis method of hydroxyoximate

A hydroxamate and synthesis method technology, applied in solid separation, organic chemistry, flotation, etc., can solve the problems of inability to precipitate hydroxamic acid, complicated operation, and increased cost, so as to avoid a large amount of acidic wastewater and improve synthesis yield rate, loss avoidance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

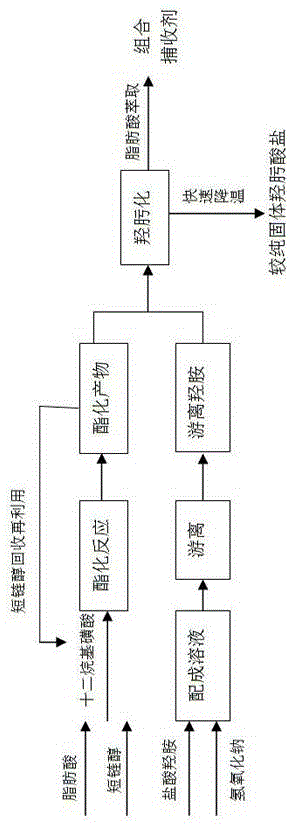

[0028] Embodiment 1, with reference to attached figure 1 , a kind of synthetic method of hydroxamate, this method uses fatty acid, short-chain alcohol, dodecylsulfonic acid, hydroxylamine hydrochloride and caustic alkali to divide into two steps and synthesize hydroxamate, and its concrete steps are as follows:

[0029] (1) Preparation of fatty acid ester: Add fatty acid, short-chain alcohol and dodecylsulfonic acid into the reactor, the ratio of the three substances is, fatty acid: short-chain alcohol: dodecylsulfonic acid=1: 3: 0.10, stirred and reacted at 75°C for 4 hours; the reactant was distilled under reduced pressure to obtain fatty acid ester, and unreacted alcohol was recovered;

[0030] (2) Preparation of hydroxamate: add hydroxylamine hydrochloride solution in another reactor, add caustic alkali in batches under stirring condition, the ratio of hydroxylamine hydrochloride to caustic alkali is 1:2, after adding caustic Stir and mix for 10 minutes after alkali; add ...

Embodiment 2

[0031] Embodiment 2, a kind of synthetic method of hydroxamate, this method uses fatty acid, short-chain alcohol, dodecylsulfonic acid, hydroxylamine hydrochloride and caustic alkali to synthesize hydroxamate in two steps, and its specific steps are as follows:

[0032] (1) Preparation of fatty acid ester: Add fatty acid, short-chain alcohol and dodecylsulfonic acid into the reactor, the ratio of the three substances is, fatty acid: short-chain alcohol: dodecylsulfonic acid=1: 8: 0.15, stirred and reacted at 100°C for 8 hours; the reactant was distilled under reduced pressure to obtain fatty acid ester, and unreacted alcohol was recovered;

[0033] (2) Preparation of hydroxamate: Add hydroxylamine hydrochloride solution in another reactor, add caustic alkali in batches under stirring condition, the ratio of hydroxylamine hydrochloride to caustic alkali is 1: 2.2, after adding Stir and mix for 20 minutes after the base; add fatty acid ester, the ratio of fatty acid ester to hyd...

Embodiment 3

[0034] Embodiment 3, a kind of synthetic method of hydroxamate, this method uses fatty acid, short-chain alcohol, dodecylsulfonic acid, hydroxylamine hydrochloride and caustic alkali to synthesize hydroxamate in two steps, and its specific steps are as follows:

[0035] (1) Preparation of fatty acid ester: Add fatty acid, short-chain alcohol and dodecylsulfonic acid into the reactor, the ratio of the three substances is, fatty acid: short-chain alcohol: dodecylsulfonic acid=1: 5: 0.12, stirred and reacted at 85°C for 6 hours; the reactant was distilled under reduced pressure to obtain fatty acid ester, and unreacted alcohol was recovered;

[0036] (2) Preparation of hydroxamate: add hydroxylamine hydrochloride solution in another reactor, add caustic alkali in batches under stirring condition, the ratio of hydroxylamine hydrochloride to caustic alkali is 1:2, after adding caustic Stir and mix for 15 minutes after alkali; add fatty acid ester, the ratio of fatty acid ester to h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com