Apple peeling agent

A peeling agent and apple technology, which is applied in the field of food processing additives, can solve the problems of inability to peel by hand, large peeling loss, inability to reach processed foods, etc., and achieves the effects of good appearance and not easy browning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] An apple peeling agent comprises the following components, and the mass percentages of each component are: sodium hydroxide 3%; surfactant 0.5%; auxiliary agent: 0.3%; water: the balance. And described surfactant is the mixture of glycerol fatty acid ester, carboxylic acid and Tween, and the mass ratio of described glycerol fatty acid ester, carboxylic acid and Tween is: 2:1:2, wherein, glycerol fatty acid The number of carbon atoms of the acid ester is 12, the number of carbon atoms of the carboxylic acid is 12, and the number of carbon atoms of Tween is 14. In addition, the auxiliary agents are sodium chloride, sodium citrate, hexadecimal A mixture of sodium phosphate and sucrose, and the mass ratio of the sodium chloride, sodium citrate, sodium hexametaphosphate and sucrose is 2: 2: 1: 1.

Embodiment 2

[0019] An apple peeling agent comprises the following components, and the mass percentages of each component are: potassium hydroxide 5%; surfactant 0.8%; auxiliary agent: 0.2%; water: the balance. Described surfactant is the mixture of glycerol fatty acid ester, carboxylic acid and Tween, and the mass ratio of described glycerol fatty acid ester, carboxylic acid and Tween is: 2:3:1, wherein, glycerol fatty acid The number of carbon atoms of the ester is 14, the number of carbon atoms of the carboxylic acid is 12, and the number of carbon atoms of Tween is 12. In addition, the auxiliary agents are sodium chloride, sodium citrate, hexametaphosphoric acid The mixture of sodium and sucrose, and the mass ratio of described sodium chloride, sodium citrate, sodium hexametaphosphate and sucrose is: 2: 1: 3: 1.

Embodiment 3

[0021] An apple peeling agent comprises the following components, and the mass percentages of each component are: potassium hydroxide 4%; surfactant 0.6%; auxiliary agent: 0.3%; water: the balance. Described surfactant is the mixture of glycerol fatty acid ester, carboxylic acid and Tween, and the mass ratio of described glycerol fatty acid ester, carboxylic acid and Tween is: 2:2:1, wherein, glycerol fatty acid The number of carbon atoms of the ester is 13, the number of carbon atoms of the carboxylic acid is 13, and the number of carbon atoms of Tween is 12. In addition, the auxiliary agents are sodium chloride, sodium citrate, hexametaphosphoric acid A mixture of sodium and sucrose, and the mass ratio of sodium chloride, sodium citrate, sodium hexametaphosphate and sucrose is 2: 2: 2: 1.

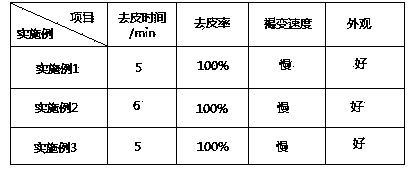

[0022] Utilize the peeling agent described in above-mentioned embodiment 1-3 to carry out peeling process to apple, and its result is as shown in table 1:

[0023] Table 1: Application r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com