Mixed phosphate and caustic alkali solution for preparing monocrystal silicon textured surfaces

A technology of orthophosphate and mixed solution, which is applied in crystal growth, chemical instruments and methods, post-processing details, etc., can solve problems such as uneven pyramid size and chromatic aberration on the surface of silicon wafers, and achieve good consistency and uniformity on the surface of silicon wafers Good performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

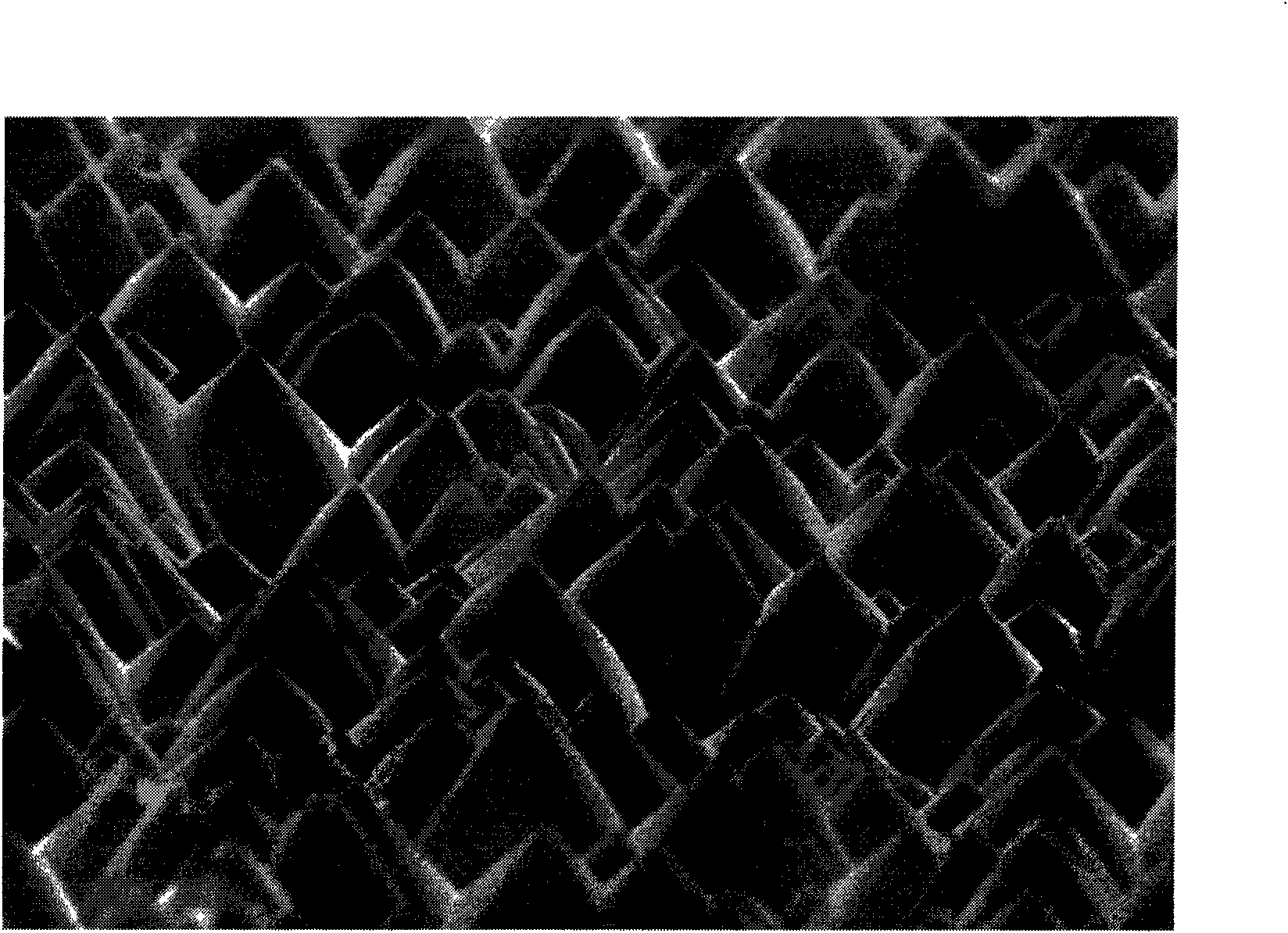

[0012] Reference figure 1 , This specific embodiment adopts the following technical scheme: 210g sodium orthophosphate (Na 3 PO 4 ), 240g sodium hydroxide (NaOH), 1500mL isopropanol were added to 30L deionized water, stirred well, mixed uniformly, and added to 80°C. Then put the cut, non-textured monocrystalline silicon wafer with an area of 125mm×125mm into the solution for etching. The etching time is 25 minutes. The quality of each monocrystalline silicon wafer before and after the etching is poor (the amount of thinning) ) Is about 0.5g. The resulting suede pyramid is uniform in size and the surface of the silicon wafer is uniform.

[0013] Take every 50 silicon wafers as a batch and add them to the above solution for etching and texturing. After each batch of silicon wafers is etched, before the next batch of silicon wafers is etched and texturing, 25g of hydrogen must be added to the etching solution. Sodium oxide and 200 mL of isopropanol. In this embodiment, 16 batch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com