Recovery method of rough ferro-nickel alloy and application of recovery method

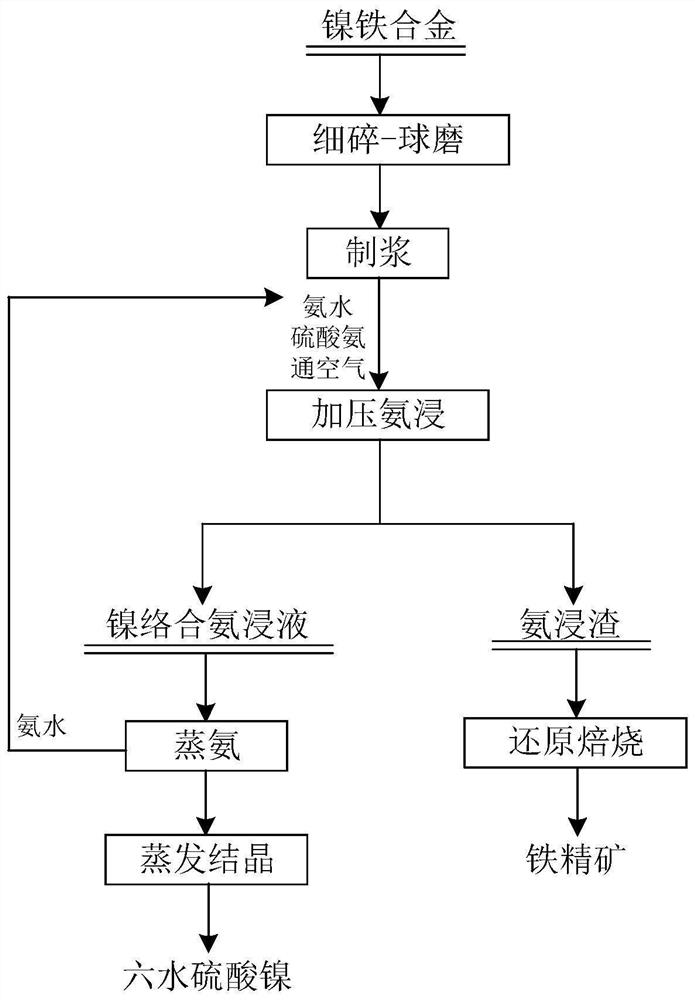

A recovery method and a nickel-iron alloy technology are applied in the recovery field of crude nickel-iron alloys, which can solve the problems of iron concentrates with a purity of less than 80%, and achieve the effects of simple operation, easy control of technical conditions, and short technological process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The recovery method of the crude nickel-iron alloy of the present embodiment may further comprise the steps:

[0042] (1) Crude nickel-iron alloy (from a laterite nickel ore processing plant product in Indonesia) (composition in the crude nickel-iron alloy is: Fe 64%, Ni 33%, C 1.2%, S 1.7%) 100g is broken, and then Use a ball mill to mill until the particle size of the nickel-iron alloy is less than 100 mesh (>95%);

[0043] (2) The ammonia water and ammonium sulfate system is configured into a leachate, and added to the nickel-iron alloy after ball milling, the liquid-solid ratio of the leachate and the nickel-iron alloy is 3:1mL / g, and the total ammonia concentration is 6mol / L, wherein the sulfate radical and the ammonia The root molar concentration ratio is 1:2, put it into a closed reaction container, and the stirring speed is 400r / min. After 30 minutes of reaction, start to pass the air and heat it. After the reaction, the pH of the slurry is detected to be 9.8, ...

Embodiment 2

[0054] The recovery method of the crude nickel-iron alloy of the present embodiment may further comprise the steps:

[0055] (1) Take 100g of crude nickel-iron alloy (from a laterite nickel ore processing plant in Indonesia) (the composition of the nickel-iron alloy is: Fe64%, Ni 33%, C 1.2%, S 1.7%) 100g is crushed, and then ball mill is used Ball milling until the particle size of the nickel-iron alloy is less than 100 mesh (the particle size is less than 100 mesh and the proportion is >95%);

[0056] (2) The aqueous ammonia and ammonium sulfate system is configured into a leach solution, which is added to the above-mentioned nickel-iron alloy after ball milling. The liquid-solid ratio of the leach solution and the nickel-iron alloy is 4:1mL / g, and the total ammonia concentration is 5mol / L, wherein the sulfate radical and the ammonia The root molar concentration ratio is 1:3, put it into a closed reaction container, and the stirring speed is 400r / min. After the reaction for ...

Embodiment 3

[0066] The recovery method of the crude nickel-iron alloy of the present embodiment may further comprise the steps:

[0067] (1) Get the crude nickel-iron alloy (the composition in the nickel-iron alloy is: Fe 64%, Ni 33%, C 1.2%, S 1.7%) 100g is crushed, and then ball milled by a ball mill until the nickel-iron alloy particle size is less than 100 mesh (grain diameter less than 100 meshes accounted for >95%);

[0068] (2) The ammonia water and ammonium sulfate system is configured into a leach solution, and added to the nickel-iron alloy after ball milling, the liquid-solid ratio of the leach solution and the nickel-iron alloy is 5:1mL / g, and the total ammonia concentration is 7mol / L, wherein the sulfate radical and the ammonia The root molar concentration ratio is 1:4, wherein the solution pH=10.8 is recorded, put it into a closed reaction vessel, and the stirring speed is 500r / min, and after 30 minutes of reaction, air is started and heated, the flow rate of the air is 2.5L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com