Carbon fiber surface chemical nickel plating method

A technology of surface chemistry and carbon fiber, applied in the direction of liquid chemical plating, coating, metal material coating process, etc., can solve the problem that Fe powder cannot be removed cleanly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

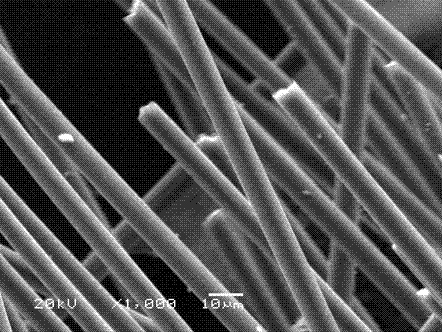

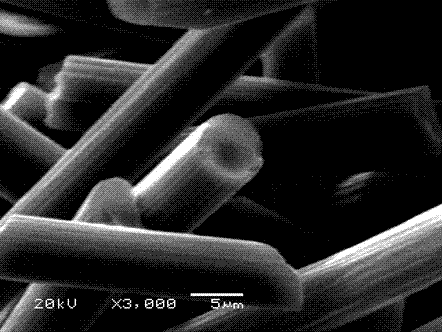

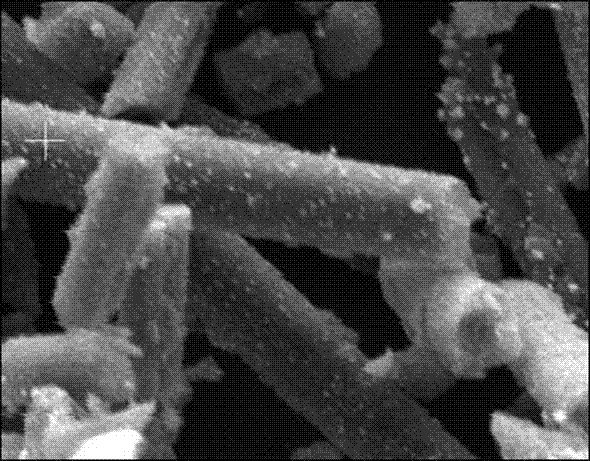

Image

Examples

Embodiment 1

[0044] The surface of the carbon fiber is electrolessly plated with nickel. First, the carbon fiber is pretreated:

[0045] (1) Degreasing treatment: burn the target carbon fiber at high temperature in a muffle furnace, burning temperature: 400℃, burning time 15min; after burning, soak in acetone solution for 10min and then take it out, in this process, ultrasonic Treat it so that the attachment can be better removed, and then rinse with deionized water to neutral.

[0046] (2) Coarsening treatment: Put the degreased carbon fiber into a coarsening solution of 98% concentrated nitric acid: 65% concentrated sulfuric acid=1:1, and ultrasonic treatment for 1h. After that, it is neutralized with NaOH and washed with deionized water to neutrality, which not only ensures the formation of gullies on the surface of the carbon fiber, but also does not weaken the strength of the carbon fiber.

[0047] (3) Sensitization treatment: sensitize the roughened carbon fiber with a sensitization soluti...

Embodiment 2

[0051] (1) Degreasing treatment: Burn 2g of carbon fiber in a muffle furnace at high temperature, burning temperature: 450℃, burning time 13min; after burning, soak in acetone solution for 6min and take it out, and ultrasonic Treat it so that the attachment can be better removed, and then rinse with deionized water to neutral.

[0052] (2) Roughening treatment: Put the degreased carbon fiber into a roughening solution of 86% concentrated nitric acid: 70% concentrated sulfuric acid=1:1, and ultrasonic treatment for 0.5h. After titration with 1% KOH solution to neutralize to PH=7, take out the carbon fiber and further rinse with deionized water.

[0053] (3) Sensitization treatment: sensitize the roughened carbon fiber with a sensitization solution. The sensitizing solution is 25g / L SnCl 2 , 10ml / L HCl, when preparing the sensitizing solution, first dissolve concentrated HCl in deionized water, and then add SnCl 2 The particles are dissolved in an aqueous solution of HCl, and magnet...

Embodiment 3

[0057] (1) Degreasing treatment: burn the target carbon fiber at high temperature in a muffle furnace, burning temperature: 500℃, burning time 10min; after burning, soak in acetone solution for 15min and then take it out, in this process, ultrasonic Treat it so that the attachment can be better removed, and then rinse with deionized water to neutral.

[0058] (2) Coarse treatment: Put the degreased carbon fiber into a coarsening solution of 98% concentrated nitric acid: 65% concentrated sulfuric acid=1:1, and ultrasonic treatment for 1.5h. Then neutralize with NaOH solution and rinse with deionized water to neutral.

[0059] (3) Sensitization treatment: sensitize the roughened carbon fiber with a sensitization solution. The sensitizing solution is 25g / L SnCl 2 , 10ml / L HCl, when preparing the sensitizing solution, first dissolve concentrated HCl in deionized water, and then add SnCl 2 The particles are dissolved in an aqueous solution of HCl. This can prevent SnCl 2 hydrolysis. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com