Nd-Ni-Mo-P/Go chemical composite deposition layer and preparation method thereof

A deposition layer, chemical technology, applied in liquid chemical plating, coating, metal material coating process, etc., can solve the problem of corrosion resistance, friction resistance, low hardness, etc., to increase the brightness of the coating, improve the crystal orientation of the coating , the effect of excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

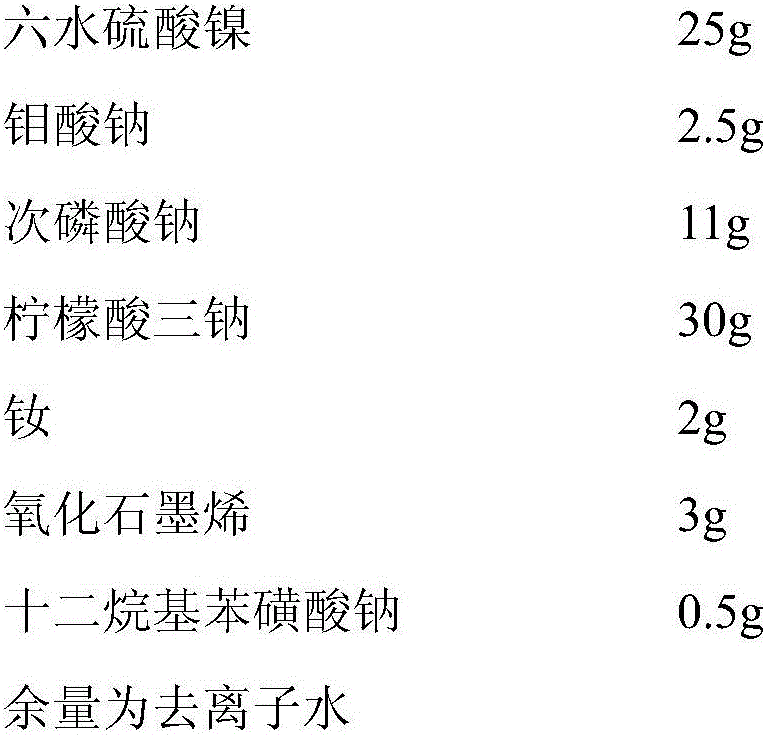

[0021] A kind of Nd-Ni-Mo-P / Go chemical composite deposition solution, calculated by every liter of solution, its composition and content are as follows:

[0022]

[0023] Add nickel sulfate hexahydrate, sodium molybdate, sodium hypophosphite, trisodium citrate, neodymium, graphene oxide, and sodium dodecylbenzenesulfonate into deionized water to dissolve, then add ammonia water to adjust the pH value to 8, That is, the Nd-Ni-Mo-P / Go chemical composite deposition solution is obtained.

Embodiment 2

[0025] The chemical composite deposition liquid of embodiment 1 gained is applied to low carbon steel surface to form Nd-Ni-Mo-P / Go chemical composite deposition layer, specifically comprises the steps:

[0026] (1) Pretreatment of the surface of the low-carbon steel workpiece, the surface of the low-carbon steel workpiece is polished and decontaminated by No. 1, 4, and No. 7 sandpaper in turn, and then degreased with acetone for 1 minute under the assistance of ultrasonic cleaning, and rinsed with deionized water 10 seconds; then pickling with 10% hydrochloric acid by mass percentage concentration for 15 seconds, and rinsing with deionized water for 10 seconds.

[0027] (2) Put the low-carbon steel workpiece pretreated in step 1 into the prepared Nd-Ni-Mo-P / Go chemical composite deposition solution, control the solution temperature at 85°C, the ultrasonic intensity at 150W, and the ultrasonic frequency Take it out after 1 hour at 20KHZ, wash it with deionized water, and blow ...

Embodiment 3

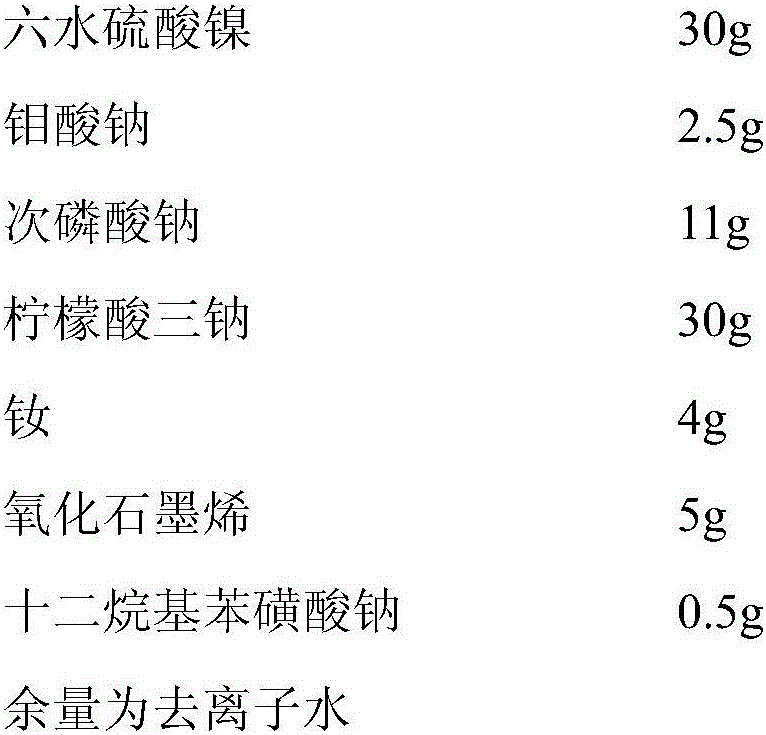

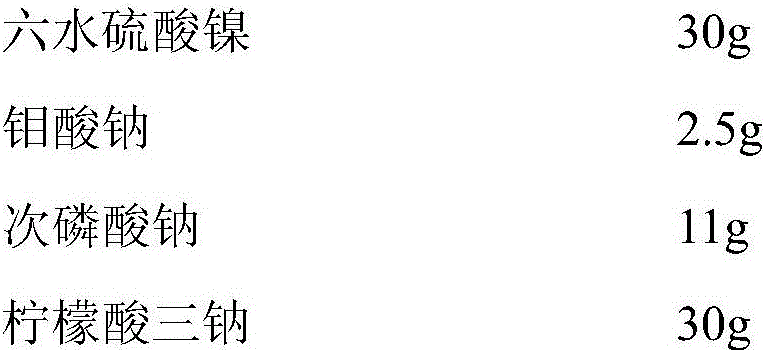

[0029] A kind of Nd-Ni-Mo-P / Go chemical composite deposition solution, calculated by every liter of solution, its composition and content are as follows:

[0030]

[0031] Add nickel sulfate hexahydrate, sodium molybdate, sodium hypophosphite, trisodium citrate, neodymium, graphene oxide, and sodium dodecylbenzenesulfonate into deionized water to dissolve, then add ammonia water to adjust the pH value to 8, That is, the Nd-Ni-Mo-P / Go chemical composite deposition solution is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion rate | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com