Anti-crack alkalis excited ecological cement

An alkali-activated cement and cement technology, applied in cement production, etc., can solve problems such as poor crack resistance, achieve good crack resistance, good freeze-thaw resistance, low energy consumption and carbon dioxide emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

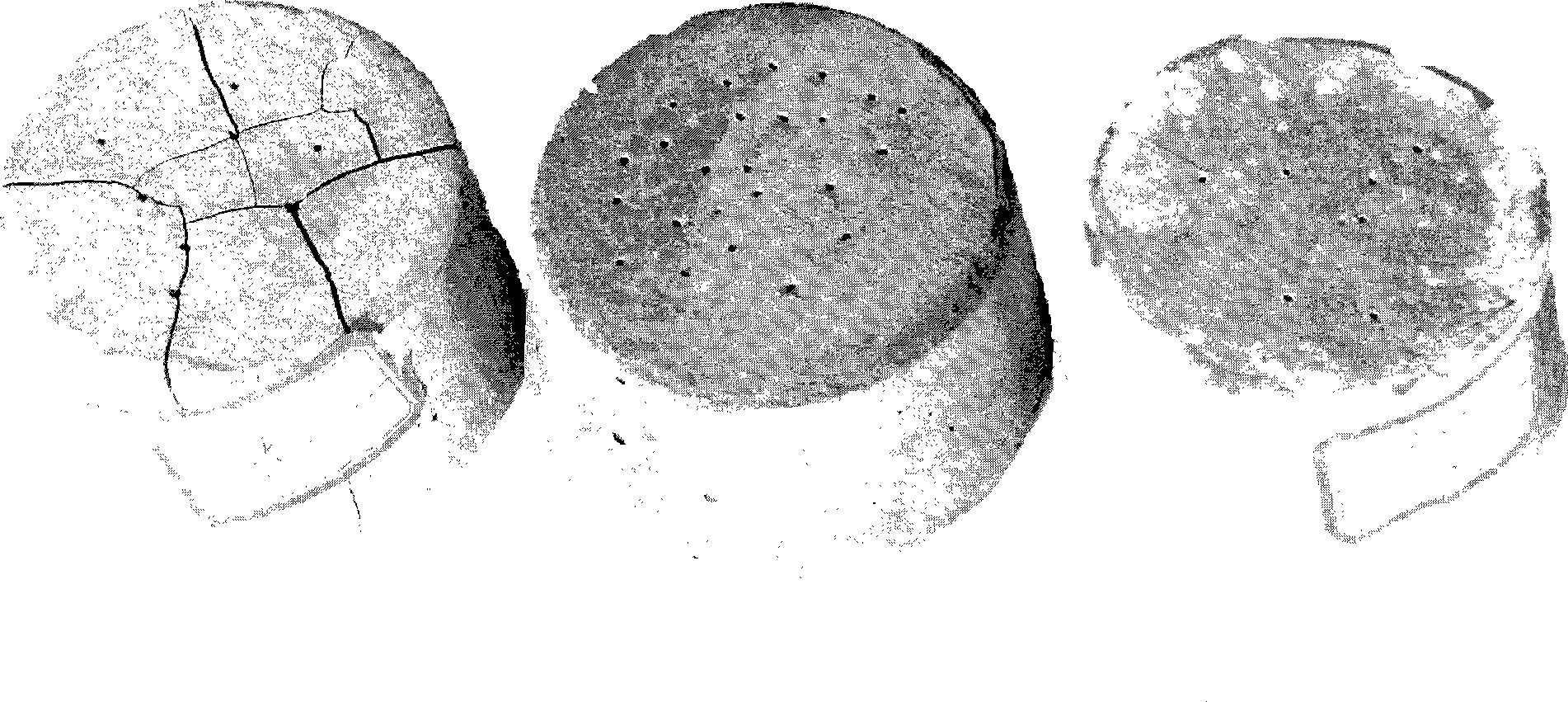

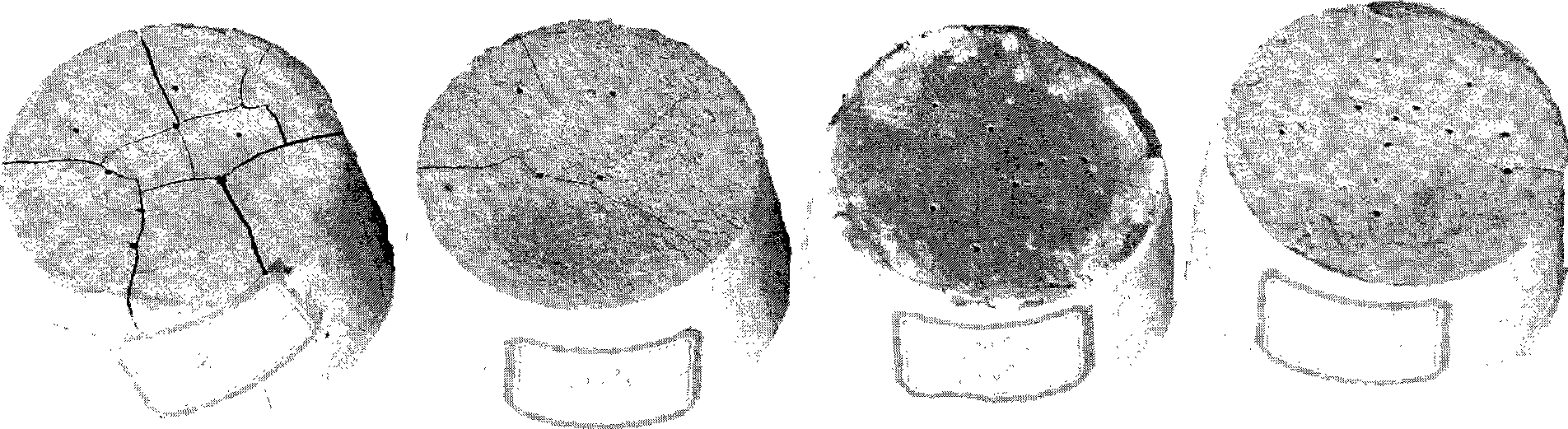

Image

Examples

Embodiment 1

[0020] The mass ratio of the anti-cracking alkali-activated cement is A:B:C=7.5:83:9.5. Among them, A is water glass with a modulus of 1; B is composed of fly ash and slag in a mass ratio of 40:60, with a specific surface area of 380m 2 / g; C is the calcination temperature of 750°C to produce activated magnesium oxide, and the water-cement ratio of the standard mortar is 0.34.

[0021] The 3-day flexural strength of the crack-resistant alkali-activated cement mortar obtained in this example is 5.06MPa, and the compressive strength is 22.7MPa; the 7-day flexural strength is 6.35MPa, and the compressive strength is 33.1MPa; the 28-day flexural strength It is 7.78MPa, and the compressive strength is 46.2MPa. Shrinkage rate of mortar: 0.00188% for 1 day, 0.00477% for 3 days, 0.00817% for 7 days, 0.00863% for 14 days, 0.00895% for 21 days, and 0.00915% for 28 days.

Embodiment 2

[0023] The mass ratio of the anti-cracking alkali-activated cement is A:B:C=9.5:83:9.5. Among them, A is water glass with a modulus of 1.2; B is composed of fly ash and slag at a mass ratio of 40:60, with a specific surface area of 680m 2 / g; C is the calcination temperature of 800°C to produce activated magnesium oxide, and the water-cement ratio of the standard mortar is 0.37.

[0024] The 3-day flexural strength of the crack-resistant alkali-activated cement mortar obtained in this example is 9.24MPa, and the compressive strength is 41.2MPa; the 7-day flexural strength is 12.12MPa, and the compressive strength is 63.2MPa; the 28-day flexural strength It is 14.33MPa, and the compressive strength is 84.6MPa. Shrinkage rate of mortar: 0.00201% for 1 day, 0.00493% for 3 days, 0.00921% for 7 days, 0.00863% for 14 days, 0.008947% for 21 days, and 0.009151% for 28 days.

Embodiment 3

[0026] The mass ratio of anti-cracking alkali activated cement is A:B:C=5:80:15. Where A is water glass with a modulus of 0.8 plus 20% Na 2 SO 4 Composition; B is composed of coal gangue and slag at a mass ratio of 60:40, with a specific surface area of 450m 2 / g; C is the calcination temperature of 800 ° C to produce activated magnesium oxide, the water-cement ratio of the standard mortar is 0.36.

[0027] The 3-day flexural strength of the crack-resistant alkali-activated cement obtained in this example is 4.46MPa, and the compressive strength is 19.1MPa; the 7-day flexural strength is 6.20MPa, and the compressive strength is 30.8MPa; the 28-day flexural strength is 7.39 MPa, the compressive strength is 50.2MPa. Shrinkage rate of mortar: 0.00201% for 1 day, 0.00504% for 3 days, 0.00932% for 7 days, 0.00874% for 14 days, 0.00912% for 21 days, and 0.00931% for 28 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com