Antisticking coating mixture for steel-smelting and preparation method threreof

A smear and anti-adhesive technology, which is applied in the fields of unshaped refractories, anti-adhesive smears for steelmaking and their preparation, can solve the problems of increased refractory materials, damage to refractory smears, and short service time, so as to reduce porosity High efficiency, not easy to hang slag, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The mass percentages of the main chemical components of the anti-stick coating material for steelmaking are: MgO 74.80%, Al 2 o 3 3.11%, CaO 2.13%, C 10.98%, SiO 2 3.45%, Fe 2 o 3 1.26%.

[0030] The specific ratio (percentage by weight) of each raw material is: 75% of waste magnesia carbon sand with a particle size of 0-3mm, 10% of waste magnesia carbon powder, 6% of fused magnesia powder, 3.5% of silicon micropowder, α-Al 2 o 3 2.0%, sodium hexametaphosphate 0.6%, calcium lignosulfonate 0.4%, soft clay 2.5%.

[0031] Weigh according to the above weight percentage, first put the fine powder into the mixer for pre-mixing for 10 minutes, then add 0-3mm granular material and stir to mix. The total kneading time is 20 minutes after discharge, sampling inspection, weighing and packaging. spare.

Embodiment 2

[0033] The mass percentages of the main chemical components of the anti-stick coating material for steelmaking are: MgO 79.16%, Al 2 o 3 3.77%, CaO 1.63%, C 9.08%, SiO 2 3.85%, Fe 2 o 3 1.69%.

[0034] The specific ratio (percentage by weight) of each raw material is: 70% of waste magnesia carbon sand with a particle size of 0-3mm, 8% of waste magnesia carbon powder, 12% of fused magnesia powder, 3.0% of silicon micropowder, α-Al 2 o 3 3.0%, sodium hexametaphosphate 0.6%, calcium lignosulfonate 0.4%, soft clay 3.0%

[0035] Weigh according to the above weight percentage, first put the fine powder into the mixer for pre-mixing for 10 minutes, then add 0-3mm granular material and stir to mix. The total kneading time is 20 minutes after discharge, sampling inspection, weighing and packaging. spare.

Embodiment 3

[0037] The smear provided by the present invention is compared with the performance, application and economic benefit of the previously used smear:

[0038] 1. Performance comparison

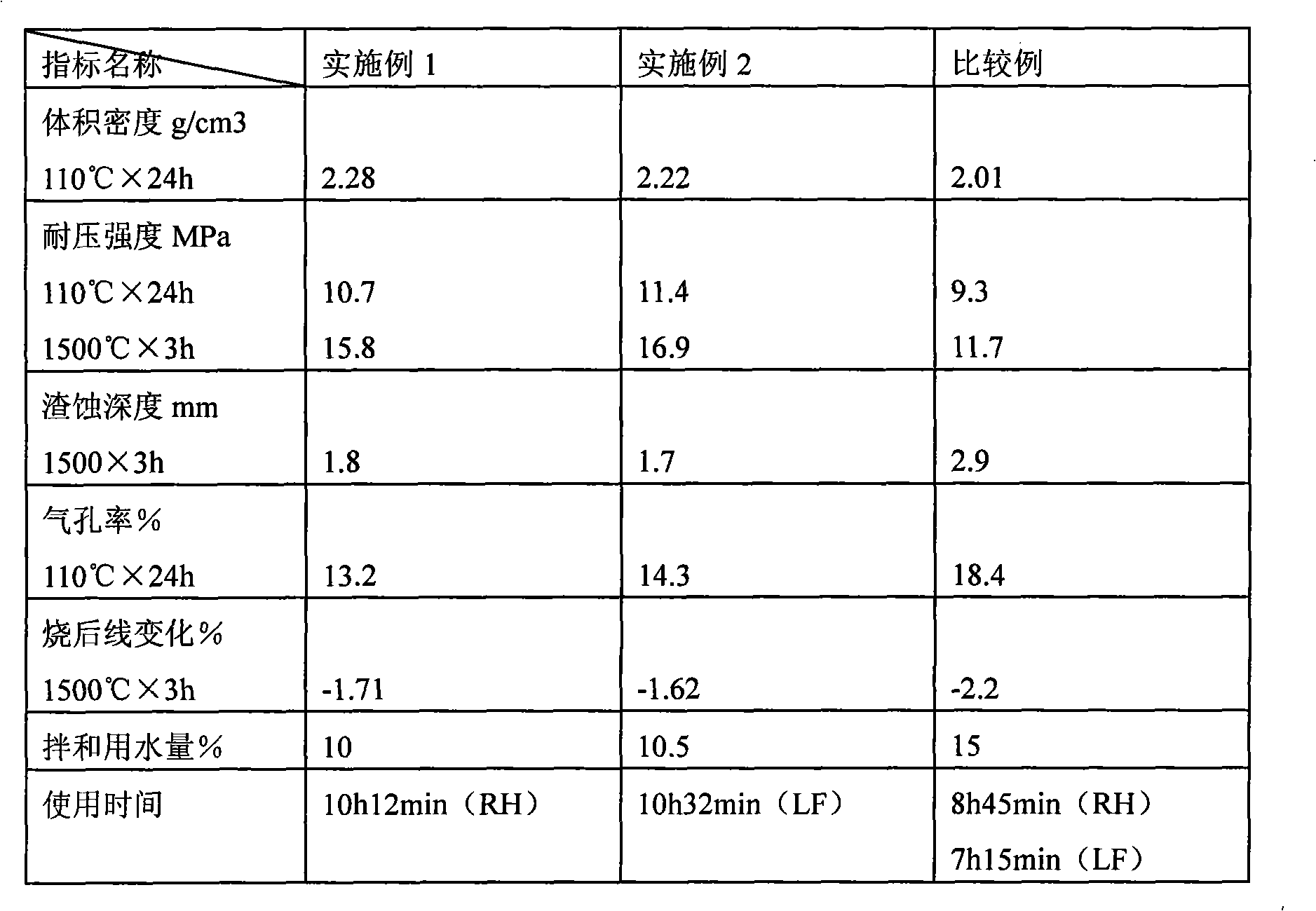

[0039] Take an appropriate amount of anti-stick coating material for steelmaking produced in Example 1, add an appropriate amount of water and stir evenly, mold it in a triple mold of 160×40×40mm and a crucible mold with an inner hole size of φ25mm×40mm, place it at room temperature for 24 hours, and demould , bake at 110°C for 24 hours, and test the drying performance indicators. Put 30g of slag material into the crucible, perform heat treatment at 1500℃φ×3h in a high-temperature furnace, cool naturally, and detect the depth of slag corrosion. The slag used in the slag resistance test is the final steelmaking slag of Panzhihua Iron and Steel Corporation. The comparative example is a conventional product. The detection indicators are as follows:

[0040]

[0041] 2. Application

[0042] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com