Inorganic thermal insulating decorative panel and production process thereof

A technology of inorganic heat preservation and production technology, which is applied in the direction of layered products, other household appliances, ceramic layered products, etc., can solve problems such as bonding of microcrystalline composite boards, and achieve faster construction speed, good comprehensive performance, and good heat preservation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

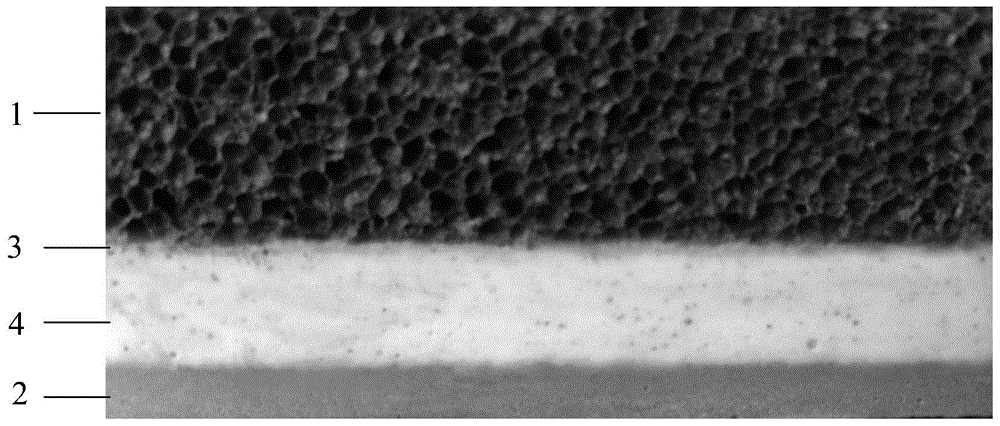

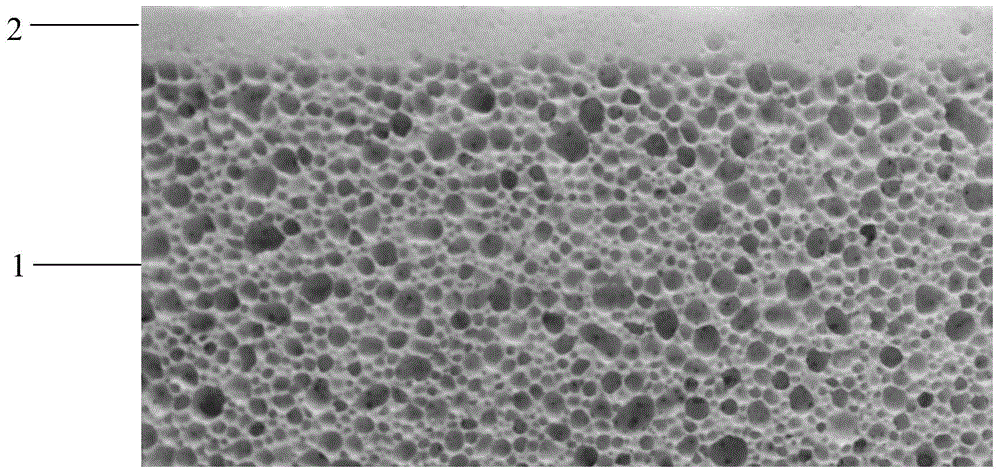

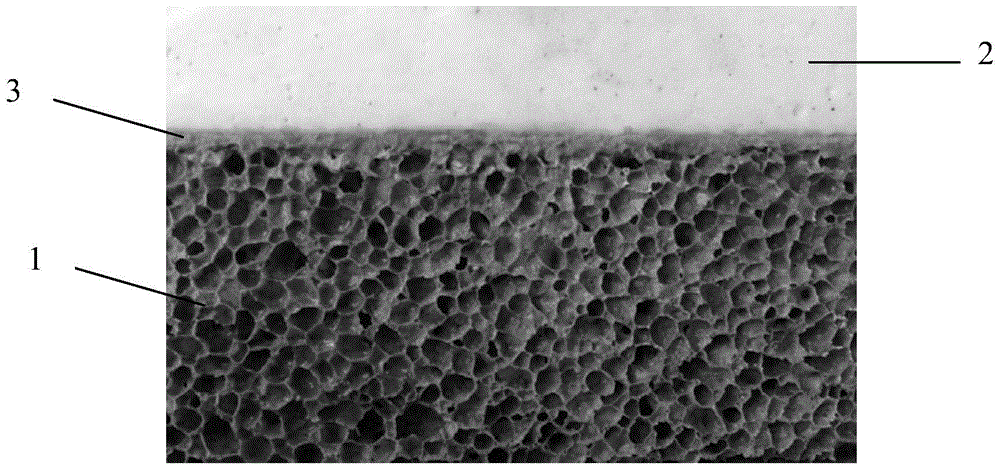

[0124] An inorganic thermal insulation decorative board, the inorganic thermal insulation decorative board includes a two-layer structure, the two-layer structure is respectively a foam base layer and a decorative layer covering it;

[0125] The base layer is a foamed ceramic layer, and the decorative layer is a microcrystalline layer;

[0126] Described whipping agent is magnesium carbonate and silicon carbide, and the mass ratio of the two is 1:1;

[0127] Described foam stabilizer is boric acid and titanium oxide, and the mass ratio of the two is 1:1;

[0128] The flux is Na 2 CO 3 .

[0129] The preparation process of the above-mentioned inorganic thermal insulation decorative board is as follows:

[0130] (1) Ingredients: the raw materials are mixed according to the proportion to obtain foaming material and decorative material respectively;

[0131] (2) Mixing: add water accounting for 110% of the total mass of the foaming material in the foaming material, fully mix ...

Embodiment 2

[0140] An inorganic thermal insulation decorative board, the inorganic thermal insulation decorative board includes a two-layer structure, the two-layer structure is respectively a foam base layer and a decorative layer covering it;

[0141] The base layer is a foamed ceramic layer, and the decorative layer is a microcrystalline layer;

[0142] Described whipping agent is magnesium carbonate and silicon carbide, and the mass ratio of the two is 2:1;

[0143] Described foam stabilizer is boric acid and titanium oxide, and the mass ratio of the two is 2:1;

[0144] The flux is titanium oxide.

[0145] The preparation process of the above-mentioned inorganic thermal insulation decorative board is as follows:

[0146] (1) Ingredients: the raw materials are mixed according to the proportion to obtain foaming material and decorative material respectively;

[0147] (2) Mixing: add water accounting for 80-150% of the total mass of the foaming material in the foaming material, fully...

Embodiment 3

[0156] An inorganic thermal insulation decorative board, the inorganic thermal insulation decorative board includes a two-layer structure, the two-layer structure is respectively a foam base layer and a decorative layer covering it;

[0157] The base layer is a foamed ceramic layer, and the decorative layer is a microcrystalline layer;

[0158] The blowing agent is K 2 CO 3 ;

[0159] Described foam stabilizer is manganese dioxide;

[0160] The flux is waste glass.

[0161] The preparation process of the above-mentioned inorganic thermal insulation decorative board is as follows:

[0162] (1) Ingredients: the raw materials are mixed according to the proportion to obtain foaming material and decorative material respectively;

[0163] (2) Mixing: add water accounting for 80% of the total mass of the foaming material in the foaming material, fully mix and remove iron, and mix in a mixer with a magnet;

[0164] (3) Drying and granulation: Add the foaming material mixed in st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com