Light heat-insulating honeycomb ceramic and preparation method thereof

A honeycomb ceramic and heat preservation technology, applied in the field of ceramics, can solve the problems of low strength, quality influence, high water absorption, and achieve the effects of firm connection, lower production cost and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] And, this embodiment also provides the preparation method of the above-mentioned lightweight thermal insulation honeycomb ceramics, including the following steps:

[0031] S1. Provide insulation layer materials and facing layer materials. The insulation layer materials include tuff mineral powder and pearls with a weight ratio of 25-50:40-90:10-30:10-30:1-15:5-15 Components of rock ore powder, expanded vitrified bead powder, glass powder, pore forming agent and sodium phosphate;

[0032] S2. Put the insulation layer material and the facing layer material into the mold for firing to form an integrated insulation layer and facing layer to obtain the light-weight heat-insulating honeycomb ceramics, or put the insulation layer material into the mold The heat-insulating layer is obtained by firing, and then the heat-insulating layer and the facing layer materials are combined through sintering or bonding to form the light-weight heat-insulating honeycomb ceramics.

[0033] ...

Embodiment 1

[0053] One-time firing to prepare lightweight thermal insulation honeycomb ceramics:

[0054] 1) Provide materials for preparing the insulation layer and the facing layer. The material formula for the insulation layer is tuff tailings powder: perlite tailings powder: expanded vitrified microbead waste tails powder: glass powder: wood chips: calcium carbonate: sodium phosphate=25: 90:30:10:0.2:6:10; the materials for the facing layer are stone powder and sodium phosphate accounting for 7% of the stone powder;

[0055] 2) Put the insulation layer into the mold by means of vibrating cloth, and then spread a 6mm-thick decorative layer material on the insulation layer material layer, and then put it into the kiln for one firing at 950°C. The firing time 40min to obtain the light-weight thermal insulation honeycomb ceramics of this embodiment.

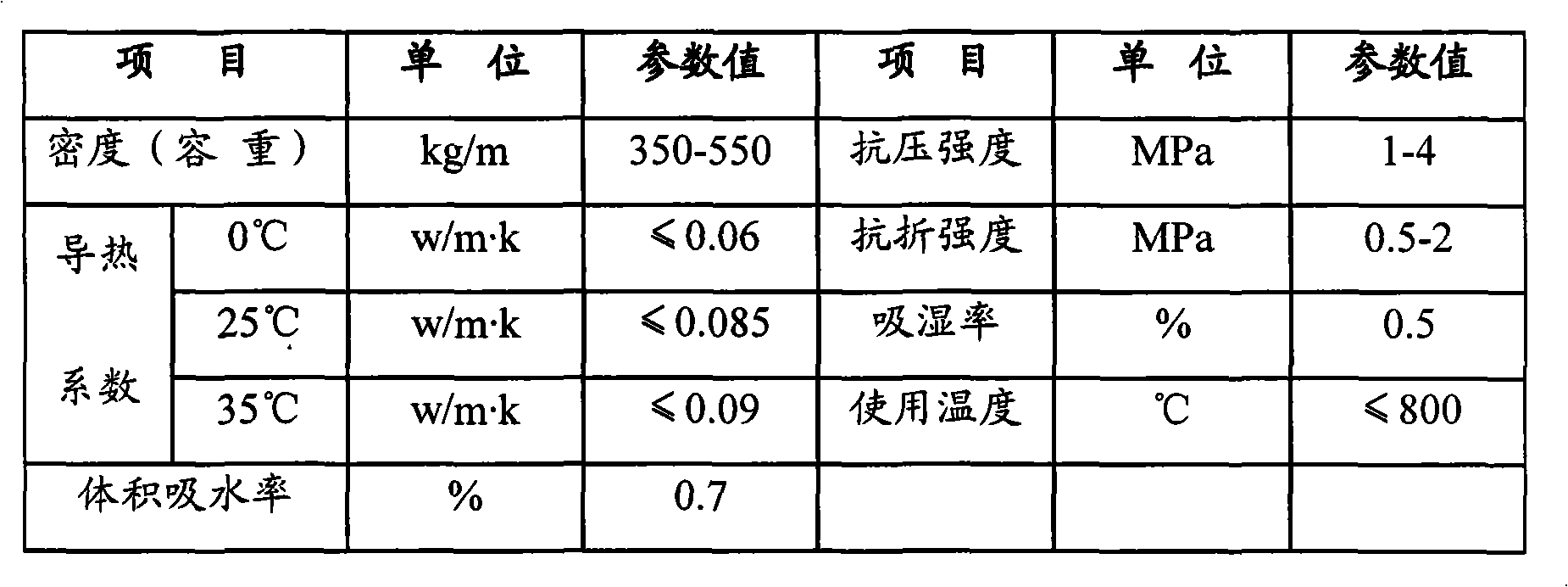

[0056] The properties of the lightweight heat-insulating honeycomb ceramics prepared in this example are shown in Table 1. It can be seen ...

Embodiment 2

[0058] One-time firing to prepare lightweight thermal insulation honeycomb ceramics:

[0059] 1) Provide materials for preparing the insulation layer and the facing layer. The material formula for the insulation layer is tuff tailings powder: perlite tailings powder: expanded vitrified microbead waste tails powder: glass powder: carbon: calcium carbonate: sodium phosphate=50: 40:10:30:0.1:10:15; the facing layer material is stone powder and sodium phosphate accounting for 3% of stone powder;

[0060] 2) Put the insulation layer into the mold by means of vibrating cloth, and then spread a 6mm-thick decorative layer material on the insulation layer material layer, and then put it into the kiln for one firing at 1000°C. The firing time 30min to obtain the light-weight thermal insulation honeycomb ceramics.

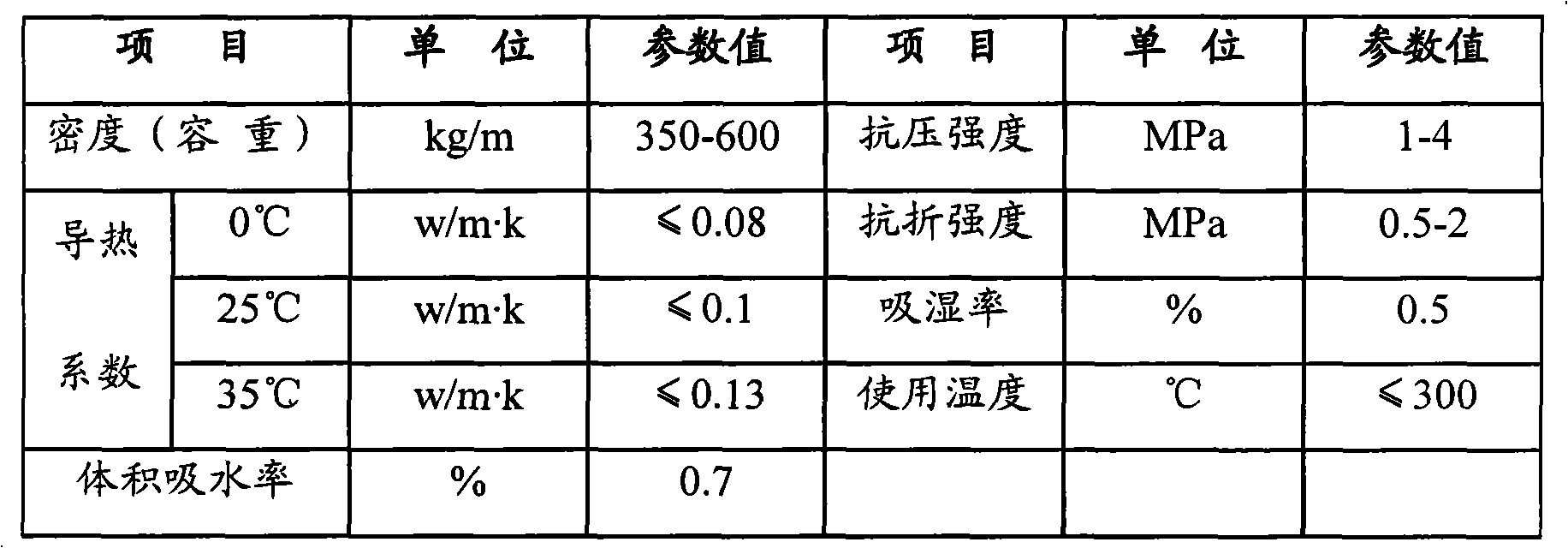

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com