Monitoring the deposition properties of an oled

a technology of deposition properties and oleds, which is applied in the direction of discharge tube luminescnet screens, semiconductor/solid-state device testing/measurement, instruments, etc., can solve the problems of not being able to measure the actual films being deposited on the substrate, requiring frequent changes, and affecting the calibration accuracy. , to achieve the effect of improving the control of the deposition process, reducing the occurrence of devices, and improving manufacturing yield loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

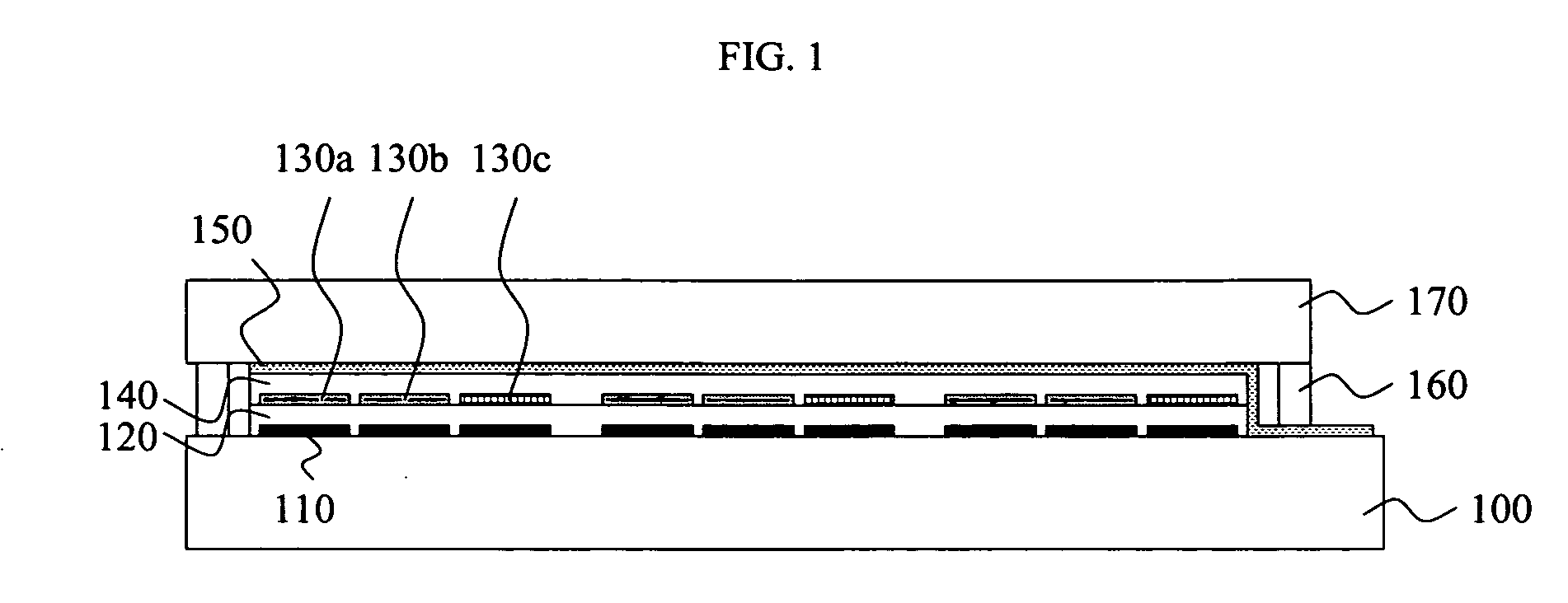

[0019] An OLED device is constructed by sandwiching two or more organic layers between a first and second electrode. In a passive matrix device, the first electrode is supplied on the device substrate forming laterally spaced rows. Alternately, in an active matrix device, thin film transistors, capacitors, and electrode lines are formed over the substrate and first electrode connections are formed on the substrate and are electrically connected to the active matrix circuitry.

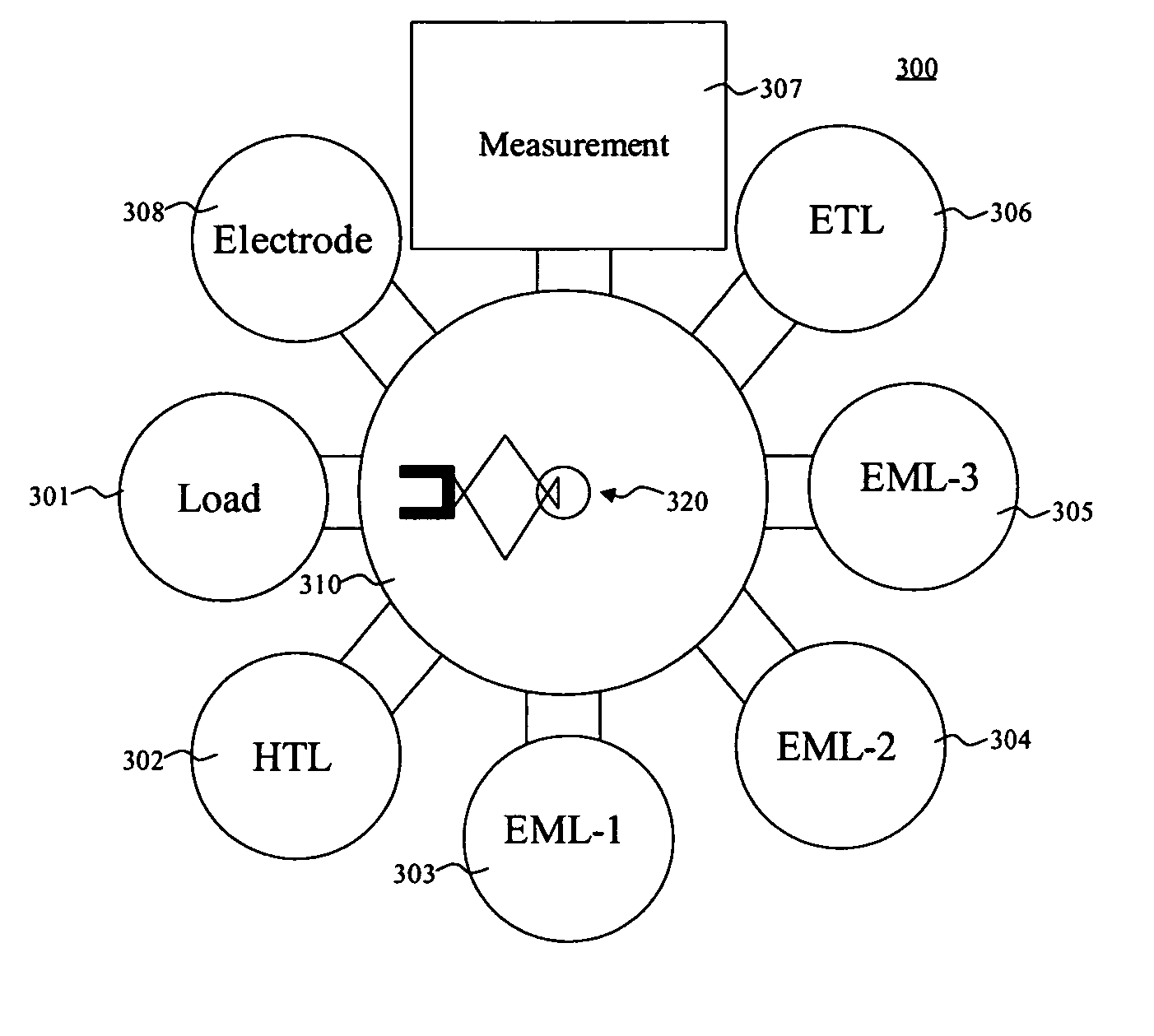

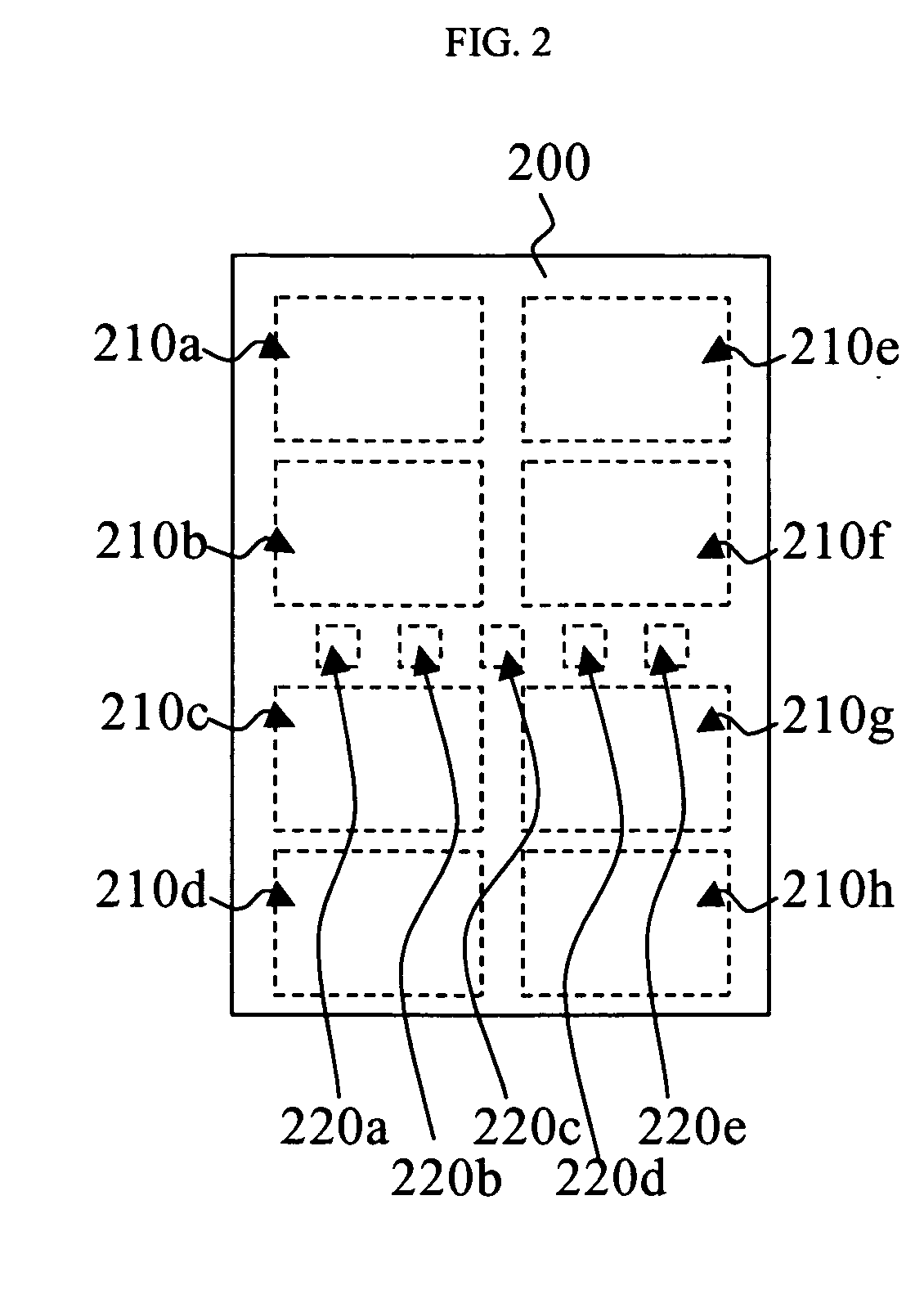

[0020] Two or more organic layers are formed over the first electrode. For example, the OLED can be formed by first depositing a hole-transporting layer, then an emission layer, and finally an electron-transporting layer. The organic layers are typically deposited by using evaporation sources where the organic materials are heated such that vapor is produced and deposited on the substrate. The layers are typically deposited in vacuum chambers. Shadowmasks are used to control where on the substrates the organic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| vacuum pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com