Four-point bending elastic parameter measuring method and four-point bending elastic parameter measuring system

A four-point bending, elastic parameter technology, applied in the direction of using a stable bending force to test the strength of materials, can solve the problems that the displacement measurement direction of the displacement sensor is difficult to achieve a coplanar state, and the measurement accuracy is low, and achieves light weight and measurement. The effect of high precision and low screw drive precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

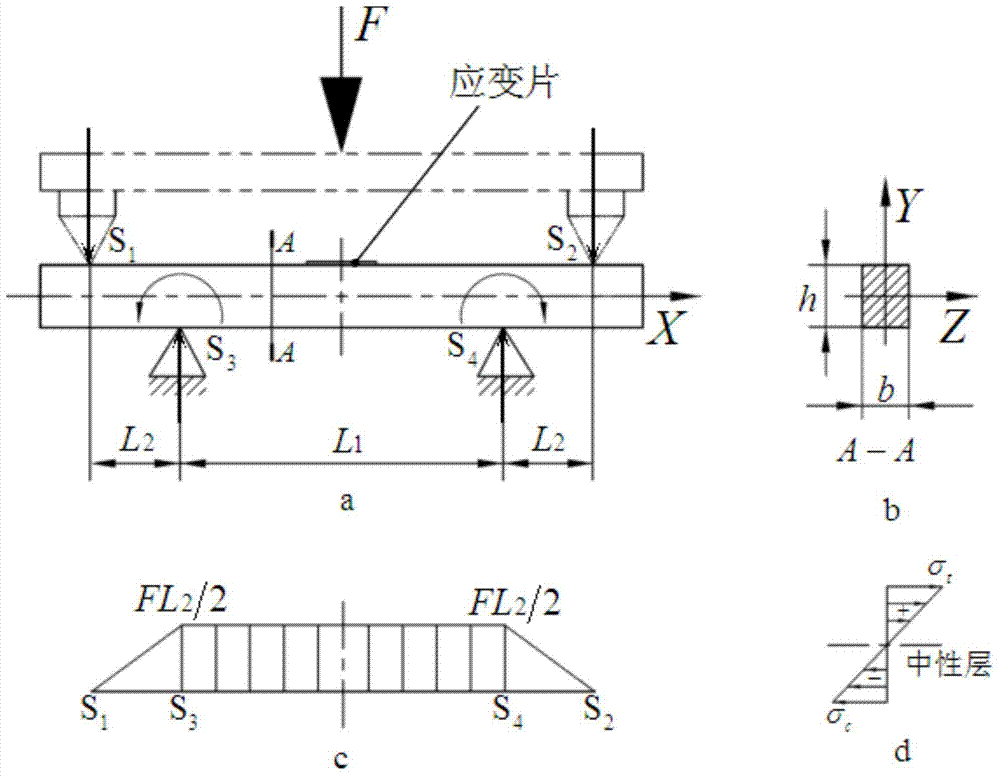

[0031] like figure 1 As shown, the four-point bending principle of a rectangular cross-section beam.

[0032] The bending force F passes through the movable fulcrum S 1 and S 2 Acting on the upper side of the beam, fixed fulcrum S 3 and S 4 acting on the underside of the beam, S 3 and S 4 The reaction force and the movable fulcrum S 1 and S 2 The force causes the beam to bend and deform. Fixed fulcrum S 3 and S 4 The section between them only bears the action of pure bending moment, the part above the neutral layer of the beam is in a pure tension state, and the part below the neutral layer is in a pure compression state. According to the Euler-Bernoulli beam theory, the theoretical value of the stress at the position of the strain gauge is shown in formula (1), and according to Hooke's law, the stress-strain relationship is shown in formula (2). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com