A clamping fiber bragg grating temperature sensor and its application method

A temperature sensor, clip-on technology, applied to thermometers, thermometers with physical/chemical changes, instruments, etc., can solve the problems of low practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

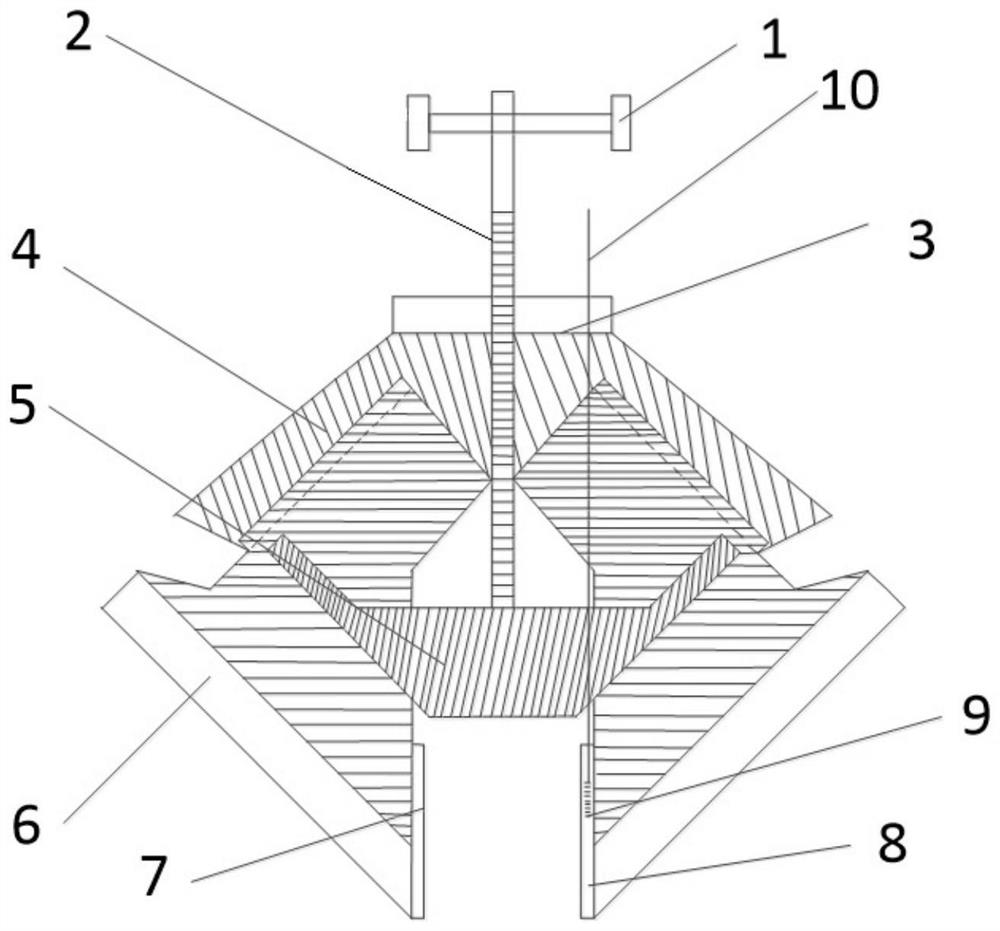

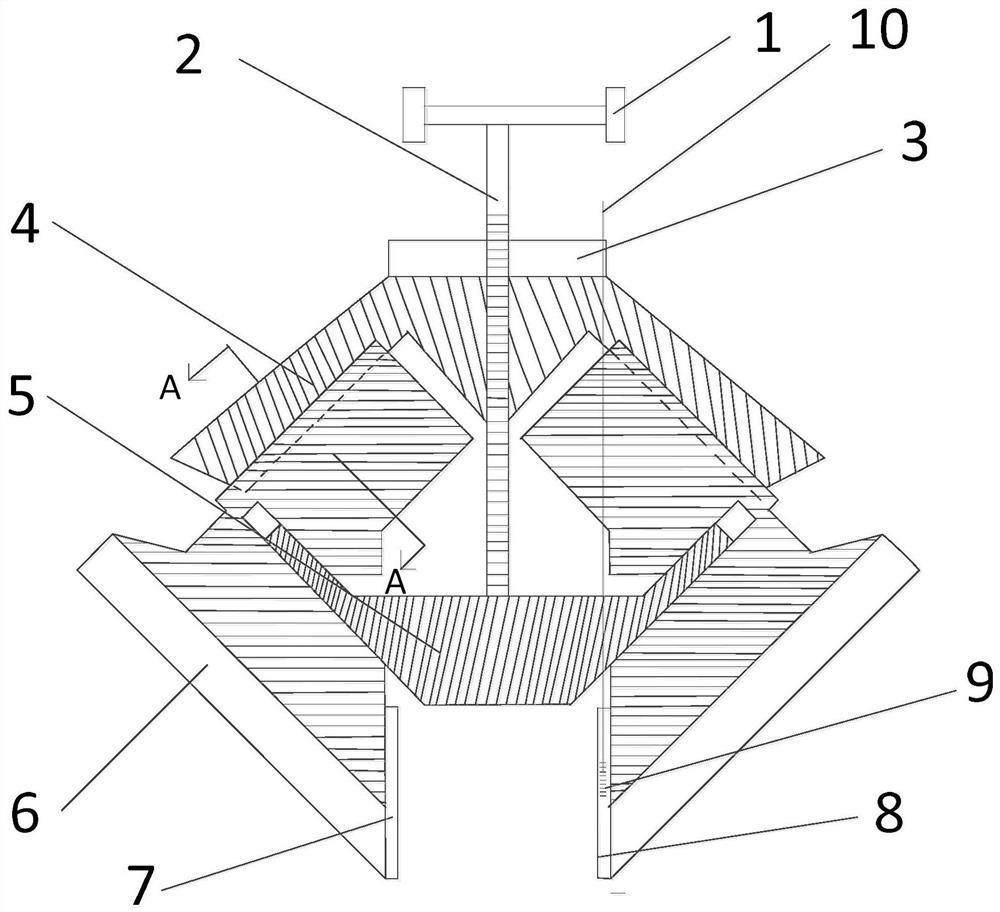

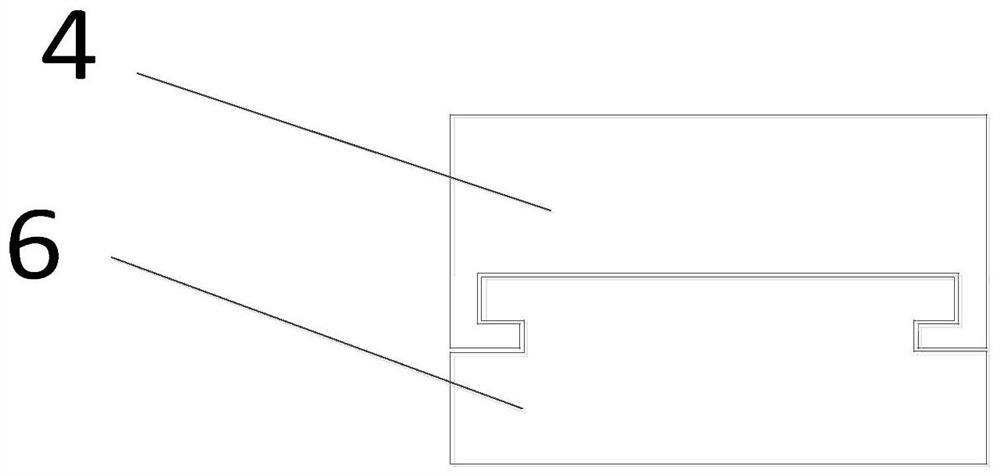

[0022] Embodiment 1: as Figure 1-3 As shown, a clamping optical fiber Bragg grating temperature sensor includes an adjustment rotating rod 1, a screw rod 2, a fixed block 3, a bottom plate 4, a control block 5, a clamp arm 6, a gasket 7, a polytetrafluoroethylene plate 8, an optical fiber Bragg grating 9, leading optical fiber 10; wherein the fixed block 3 is fixed on the base plate 4, the upper end of the clamp arm 6 is connected to the base plate 4, the upper end of the screw rod 2 is connected with the adjustment rotating rod 1, and the lower end passes through the fixed block 3 and the base plate 4 from top to bottom. It is connected with the top of the control block 5, the two ends of the control block 5 are provided with obliquely upward bosses, and the middle part of the clamp arm 6 is provided with jacks, and the two bosses of the control block 5 can be slidably inserted into the jacks of the left and right clamp arms 6 , and one side of the clamp arm 6 is provided wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com