Method and device for detecting clamping performance between vacuum electron device pipe casings and helical line

A vacuum electronic device and helix technology, which is applied in the field of optical fiber sensing and industrial measurement and control, can solve the problems of restricting output power, burning the helix, and rising temperature of slow wave structure, so as to reduce production cost, improve yield and high sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

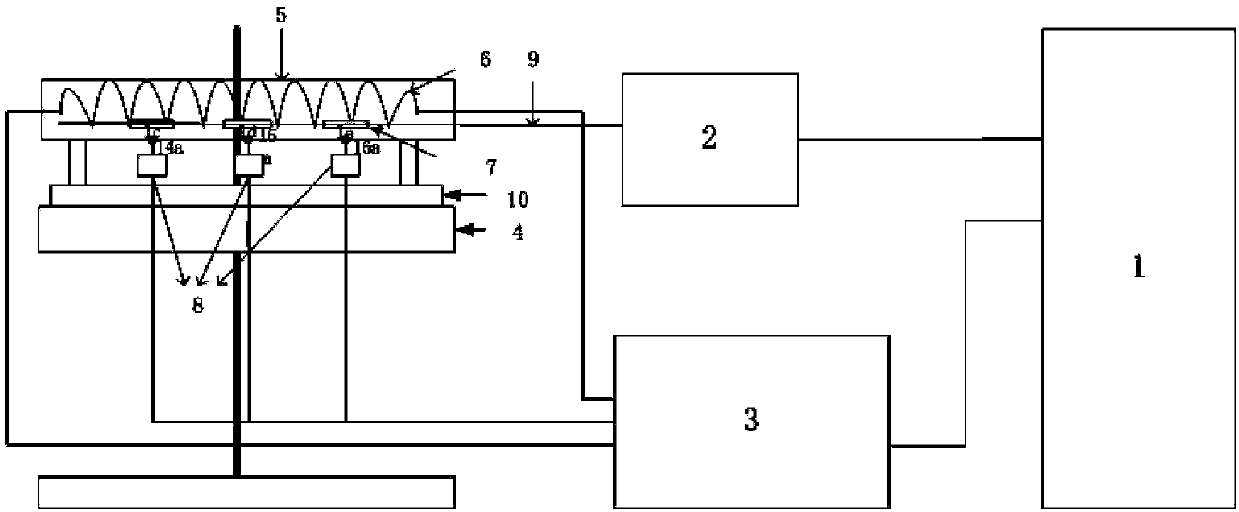

[0023] The technical content of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] A method for detecting the clamping property between the vacuum electronic device shell and the helix of the present invention, the method comprises the following steps:

[0025] The first step: place the optical fiber sensor 7 in the optical fiber line 9 in the inner cavity of the helix 6, make the optical fiber sensor 7 contact the inner wall of the helix 6, and then connect one end of the optical fiber line 9 to the optical port of the demodulator 2 connect.

[0026] The second step: fix the temperature sensor 8 on the outer wall of the vacuum electronic device shell 5, and make the probe of the temperature sensor 8 contact with the vacuum electronic device shell 5, and the probe of the temperature sensor 8 is in contact with the vacuum electronic device shell 5 The contact point between and the contact point between the optical fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com