Quality detection method of boring on printed circuit board

A technology for printed circuit boards and detection methods, which is applied to measuring devices, instruments, scientific instruments, etc., can solve problems such as high scrap rate, affecting processing steps, waste of raw materials, etc., to reduce drilling scrap rate and improve processing quality efficiency and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

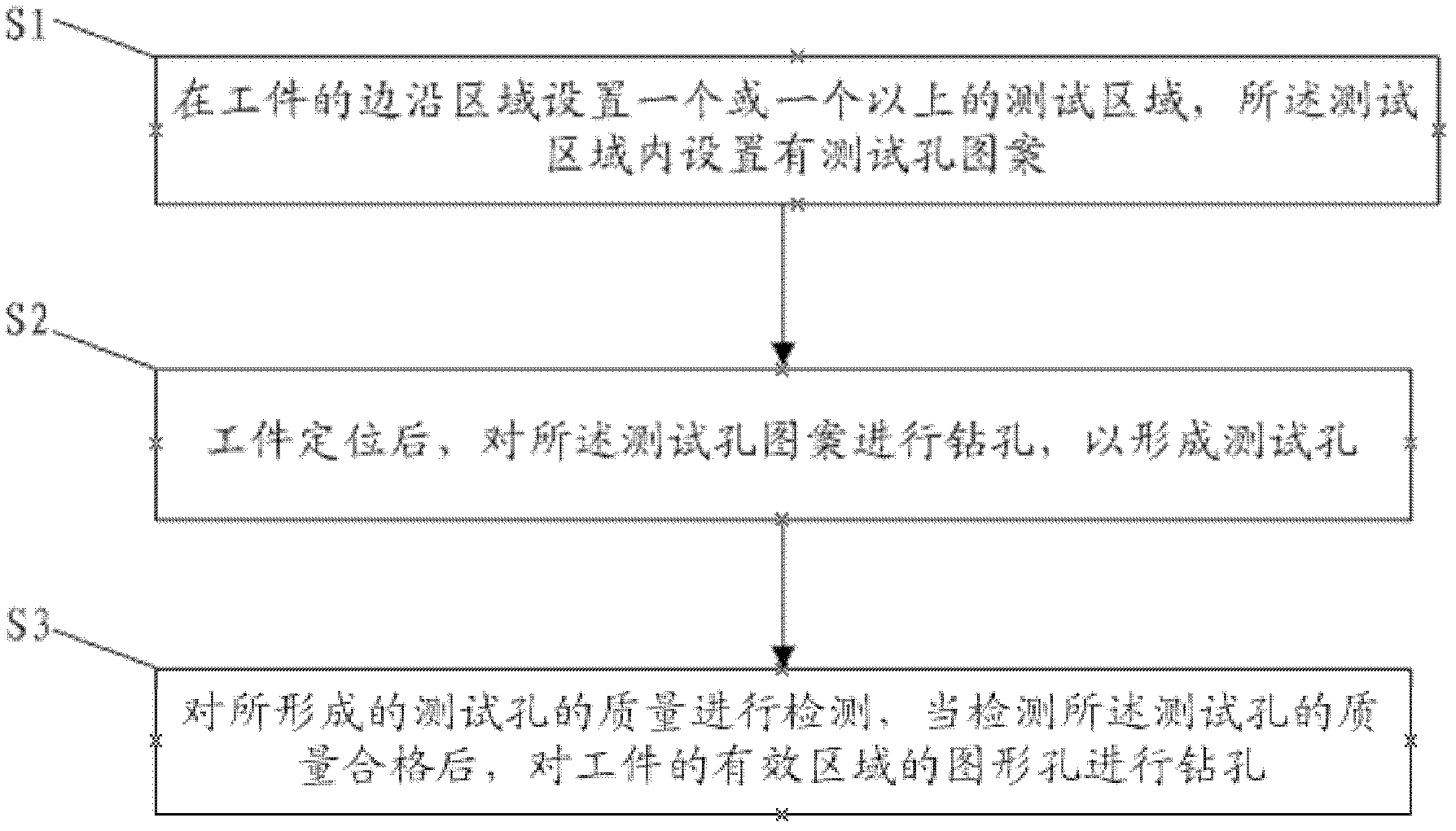

[0035] Such as figure 1 As shown, in the present embodiment, the detection method of drilling quality on the printed circuit board comprises the following steps:

[0036] S1) One or more test areas are set in the edge area of the workpiece, and test hole patterns are set in the test areas.

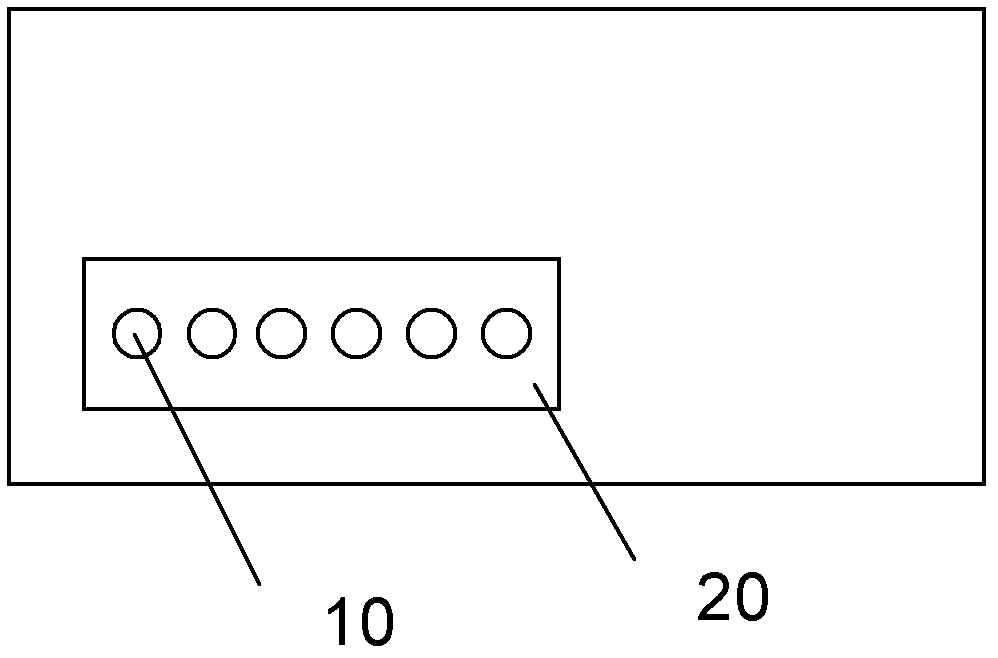

[0037] Such as Figure 5 As shown, the workpiece includes an edge region 14 and an active region 15 . There are one or more test areas, and each test area is distributed on two or more sides of the edge area of the workpiece. In this embodiment, the shape of the workpiece is a rectangular plate, and a test area 20 is respectively set at the four corners of the edge area of the workpiece, and the four test areas 20 are arranged on the four sides of the workpiece in pairs. The positions of the two test areas separated on the two opposite sides correspond to each other, so as to ensure that the drilling quality of the entire plate surface of the workpiece can be tested.

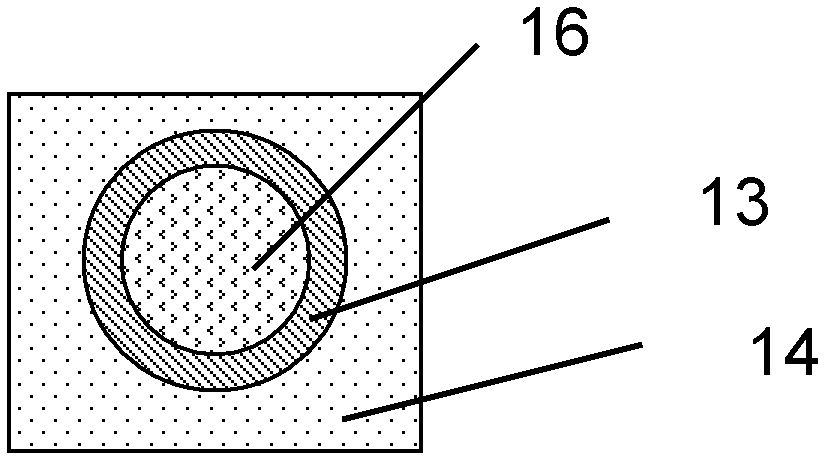

[0038] In ...

Embodiment 2

[0061] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that there are 2 test areas in the edge area of the workpiece in this embodiment, which are distributed at the diagonal positions of the workpiece, and 4 test areas are respectively arranged in each test area. 10 test holes. Compared with Embodiment 1, this embodiment is suitable for the inspection of the drilling quality of PCB boards with relatively simple graphic lines and fewer graphic holes in the effective area of the workpiece.

[0062] The pattern of the test hole, the setting of the test hole and the detection method in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

[0063] In embodiments 1 and 2, using the detection method of the drilling quality to drill the test hole in the edge area of the workpiece is different from the pattern hole drilling in the effective area of the workpiece, even if holes appear in the process of dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com