Dual-shaft synchronous stretching device

A technology of synchronous stretching and stretching frame, which is applied in the field of material stretching devices, can solve the problems of increasing device cost, complex structure, large volume, etc., achieve accurate stretching data and results, simple equipment structure, and avoid complex mechanisms Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

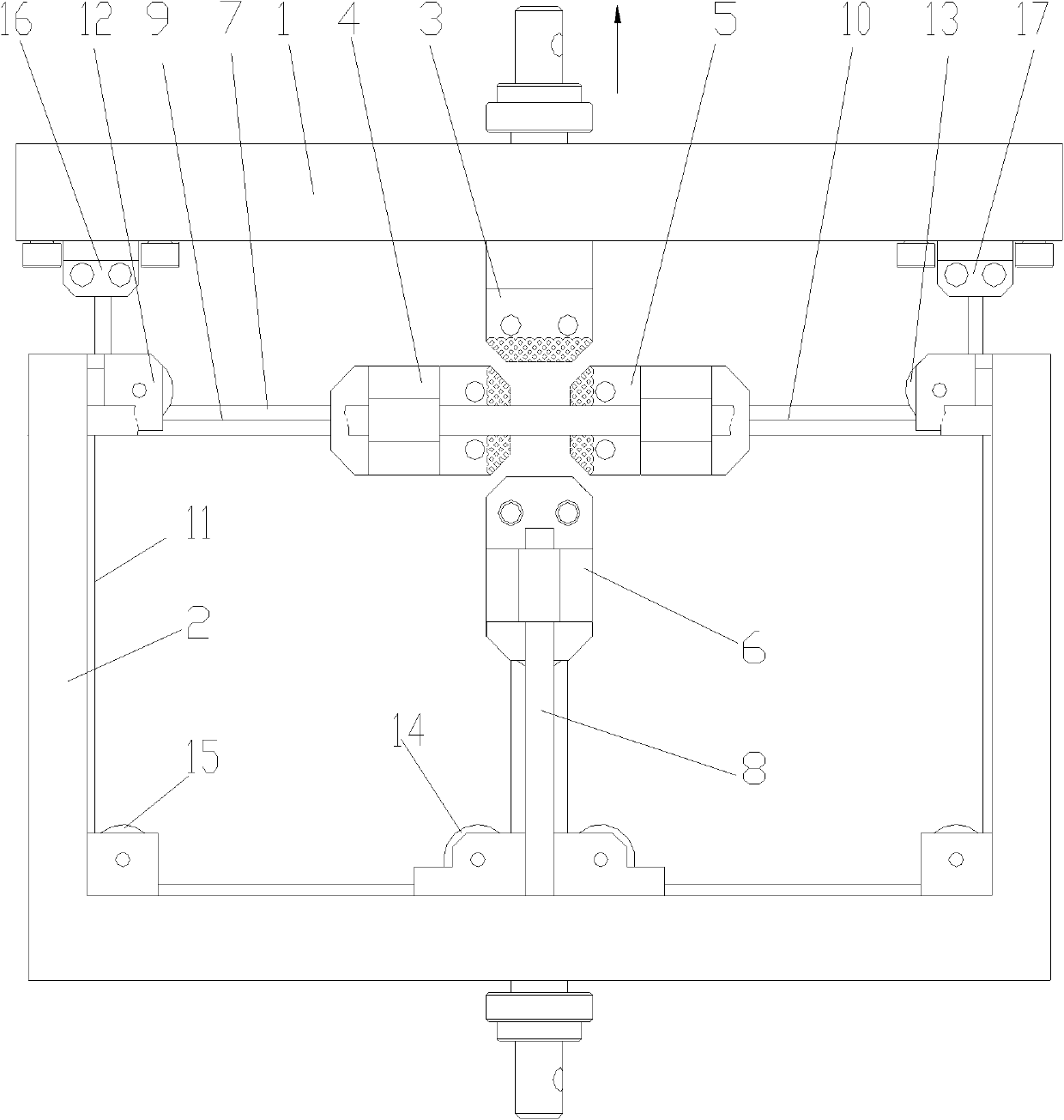

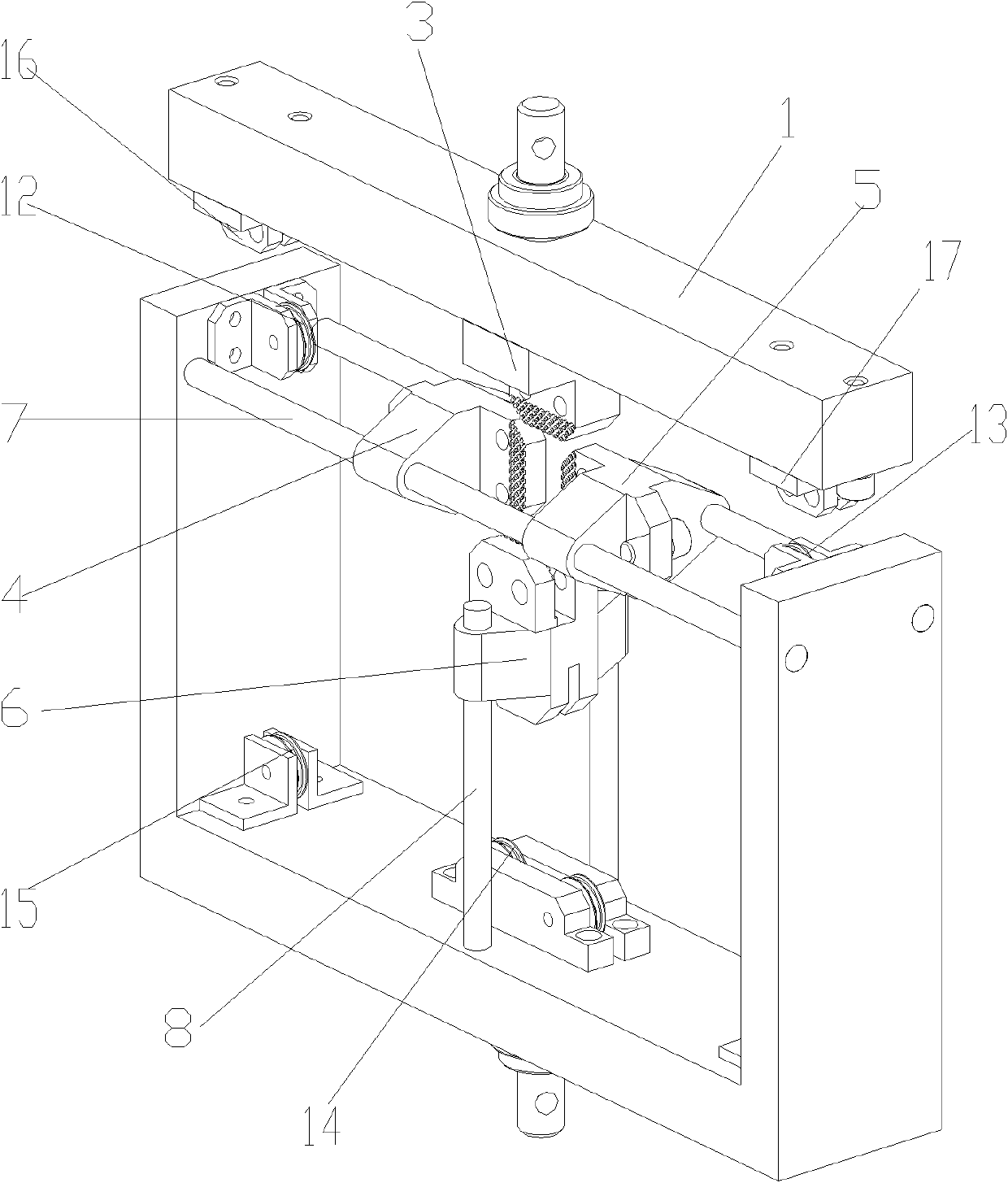

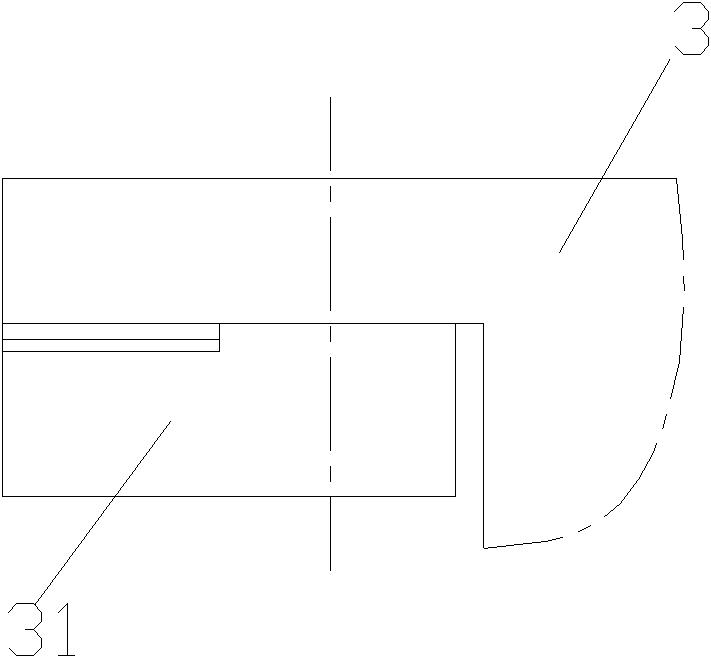

[0022] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 It is a three-dimensional schematic diagram of the structure of the present invention, image 3 It is a schematic diagram of the clamp structure of the present invention, as shown in the figure: the biaxial synchronous stretching device of this embodiment includes a fixed frame 2, a stretching frame 1 and a stretching assembly, and the stretching assembly includes a longitudinal clamp assembly and a transverse clamp assembly , the vertical clamp assembly includes a vertical clamp I3 and a vertical clamp II6 arranged oppositely, and the horizontal clamp assembly includes a horizontal clamp I4 and a horizontal clamp II5 arranged oppositely; the relative setting refers to between the vertical clamp I3 and the vertical clamp II6 and the horizontal clamp I4 It is opposite to the collet used to clamp the workpiece between the horizontal fixture II5 to achieve symmetrical stretching. It be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com