Single drum type mechanical property stretching test method and device for plastic film

A plastic film, single-roller technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of high temperature mechanical properties of plastic films, such as difficulty in testing, low precision, and excessive error, and achieve positive technical effects. It has the effect of promoting application value, simple structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

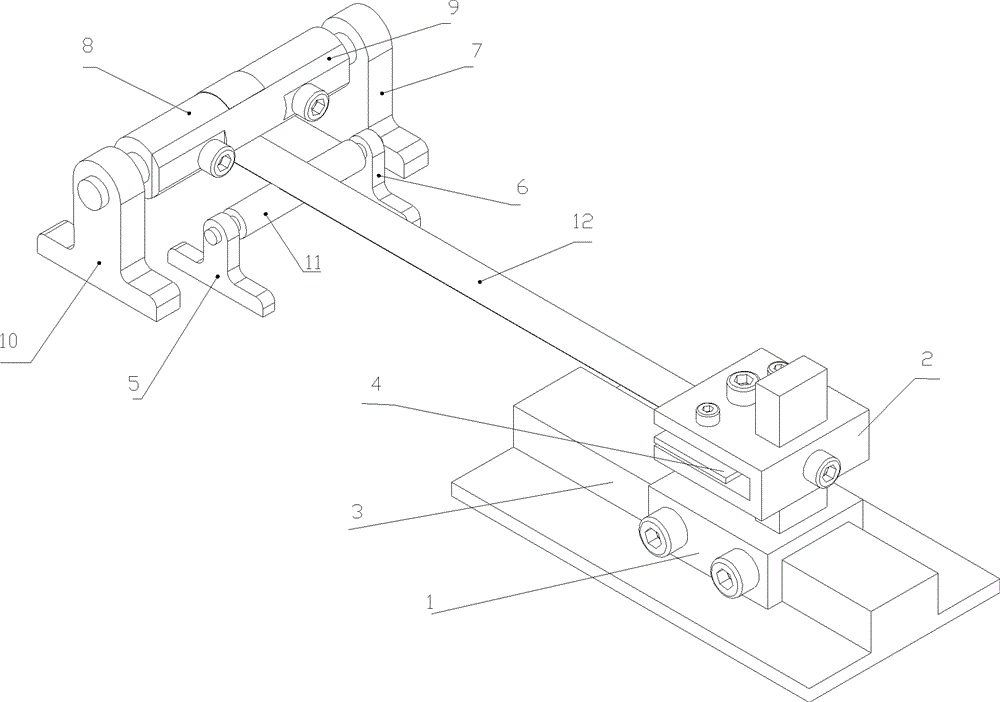

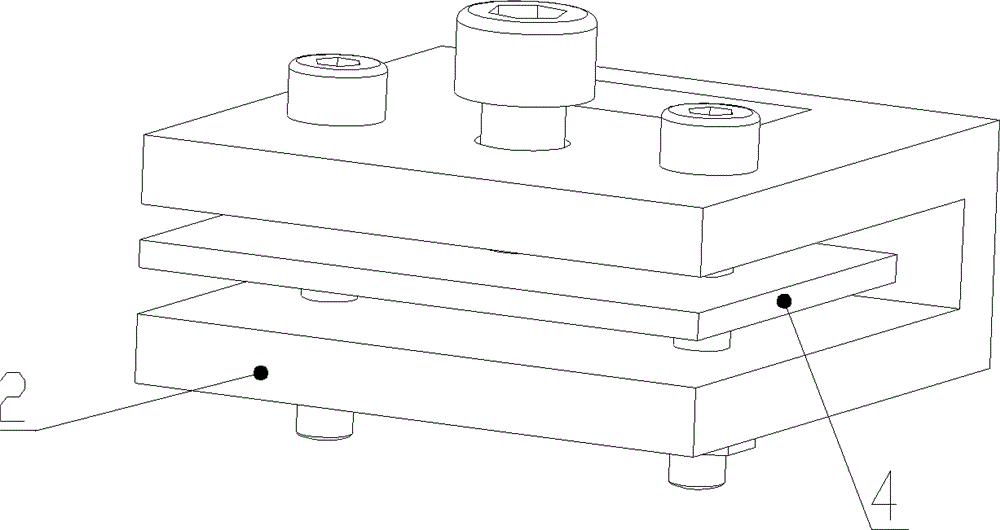

[0029] Such as figure 1 , 2 As shown, the plastic film single-roller mechanical properties tensile test device of the present invention includes a computer, an electric heating system, a transmission mechanism, a stretching mechanism, and a restraint device. The transmission mechanism is connected to the computer, and the stretching mechanism is placed in a sealed box. , the transmission mechanism includes a tension sensor, a main shaft 8, supports 7, 10, and a gasket 9, the main shaft 8 is cylindrical, and there is a plane on the middle surface, and the gasket 9 is connected to the plane by bolts, Both ends of the main shaft 8 are movably connected with supports 7, 10, and the tension sensor is arranged on the main shaft 8; the stretching mechanism includes an electric heating system, a slide block 1, a guide rail 3, a clamp 2, and a pad 4. The slider 1 is placed on the guide rail 3 to slide and cooperate with it, the clamp 2 is arranged on the slider 1, and a bolt is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com